In the fast-paced and ever-evolving world of construction, ensuring the safety and efficiency of excavation processes is paramount. Whether laying the foundation for a towering skyscraper or installing underground utilities, excavation is a fundamental part of many construction projects. However, excavations come with their own set of challenges, particularly concerning the stability of trench walls. This is where the critical technique of ‘benching’ comes into play.

In this informative blog, we will dive into the nuts and bolts of benching in excavation. We’ll start by unravelling what benching is and why it’s vital. From there, we will delve into the intricate design requirements that ensure not only the safety of the workforce but also the structural integrity of the excavation. Whether you’re a construction professional, a civil engineering student, or someone with a keen interest in construction methodologies, this blog will equip you with essential knowledge about benching in excavation. Let’s dig in!

What is Benching in Excavation?

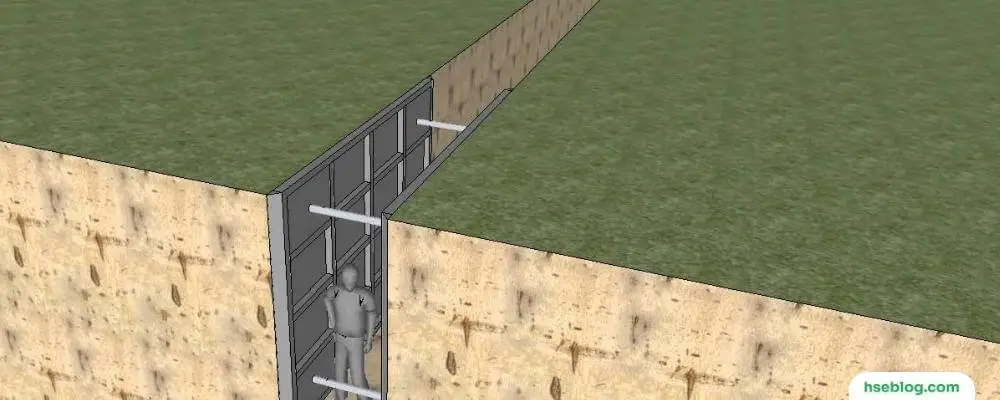

Benching in excavation is a safety method used to protect workers from potential cave-ins during the excavation process. It involves excavating the sides of an excavation to create a series of horizontal levels or steps, with near-vertical or vertical surfaces between each level. This step-like pattern, known as a ‘bench’, helps prevent the excavated walls from collapsing inward, protecting the construction workers from being trapped.

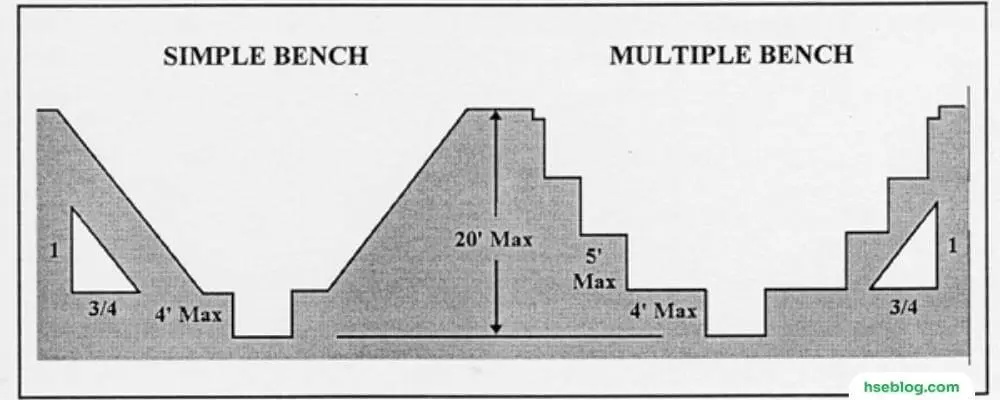

There are two basic types of benching – simple and multiple. The choice of which to use largely depends on the excavated soil type. As a rule of thumb, the bottom vertical height of the trench should not exceed 4 ft for the first bench. The maximum vertical height for subsequent benches is up to 5 ft in Type A and 4 ft in Type B, provided the total trench depth does not surpass 20 ft. However, benching is not allowed in Type C soil due to its instability.

Importance Of Benching

In construction and excavation, benching is not just a technique; it’s an essential safety measure that bears great importance. Here’s why benching is crucial:

- Prevents Soil Collapse: One of the primary reasons for employing benching is to prevent soil collapse into the excavation. The step-like structure redistributes the weight of the soil, significantly reducing the risk of cave-ins, which can be fatal or cause severe injuries to workers.

- Ensures Worker Safety: Safety is paramount in any construction environment. By providing a more stable wall structure through benching, workers can operate with a reduced risk of being trapped or injured by falling debris or collapsing walls.

- Reduces the Lateral Load: The research conducted by Iowa State University indicates that benching reduces the lateral load on conduits or utilities installed within the trench. By having benches that support some of the lateral weight of the soil, the pressure on the buried conduits is significantly reduced, enhancing the safety and integrity of the installation.

- Compliance with Safety Regulations: Benching is often a requirement under safety regulations. For example, in the United States, OSHA (Occupational Safety and Health Administration) requires deep trenches of five feet or greater to have a protective system such as benching. Complying with these regulations is important for worker safety and avoiding fines and legal issues.

- Facilitates Work Processes: A benched excavation can facilitate workers’ ease of movement and operation within the trench. It can also provide spaces for keeping tools or materials, making the workflow more efficient.

- Adaptability to Soil Type: Benching can be adapted according to the type of soil – Type A (most stable) or Type B. The design criteria change based on the soil type, making benching a versatile technique for varying conditions. However, it’s important to note that benching is unsuitable for Type C soils, which are the least stable.

- Reduces Economic Losses: Cave-ins not only risk lives but can also severely impact the timeline and budget of a project. By utilizing benching to reduce the risk of collapse, projects can avoid unexpected costs and delays associated with accidents.

- Boosts Confidence and Morale: Knowing that safety measures like benching are in place can boost the confidence and morale of the workers. When the workforce knows their safety is taken seriously, it can increase productivity and job satisfaction.

Benching is an indispensable technique in excavation projects. Its importance lies in safeguarding human lives, ensuring the structural integrity of the excavation, compliance with regulations, and in contributing to the economic feasibility and efficiency of construction projects.

Design Requirements for Benching in Excavation

Designing an effective and safe benching system is a complex process that requires meticulous consideration of various factors. Below, the previously mentioned design requirements are expanded upon, and additional points are included for a comprehensive understanding.

1. Excavation Size and Shape:

Before embarking on the design process, it is imperative to clearly understand the excavation’s dimensions, including its depth, width, and length. Additionally, the shape of the excavation is essential as it could be rectangular, trapezoidal, or another geometric form. Understanding the size and shape will help calculate the volume of material to be excavated and influence the arrangement of benches.

2. Soil Type:

Soil analysis is a critical component. Soils are classified into various types, typically Type A, B, and C, with Type A being the most stable and Type C being the least. Understanding the soil type helps in determining the angle and depth of benches. For instance, Type A soil can support steeper benches compared to Type B. Type C soil, being unstable, isn’t suitable for benching.

3. Weight of Materials:

Considering the weight of the materials involved includes both the soil and any equipment or structures that will be placed within the excavation. Overloading the benches can cause them to collapse. Engineers must calculate the load each bench can safely support to ensure stability.

4. Availability of Equipment:

Equipment availability, size, and capabilities are significant in designing a benching system. Large excavators may be needed for deep excavations, while smaller equipment may suffice for shallow ones. Additionally, specialized equipment like soil compactors might be necessary depending on the soil type.

5. Local Regulations and Guidelines:

It is crucial to be aware of and adhere to local regulations and guidelines regarding excavation and benching. Different regions may have specific requirements for bench heights, angles, and other aspects of benching that must be incorporated into the design.

6. Environmental Factors:

Environmental conditions such as rainfall, groundwater level, and temperature can impact the stability of an excavation. For instance, additional drainage might be necessary in areas with high rainfall to prevent water from weakening the excavation walls.

7. Worker Access and Egress:

The benching design should facilitate safe access and egress for workers. This might include incorporating steps or ramps into the benching and ensuring these access points are located at appropriate intervals along the excavation.

8. Monitoring and Adjustment:

An effective benching design should include provisions for ongoing monitoring and adjustment. This might involve regular inspections to check for signs of instability and a plan for making necessary adjustments to the benching system in response to changing conditions.

9. Training and Safety Protocols:

The design process should also consider the training and safety protocols necessary for workers. This includes ensuring that workers are trained in the correct procedures for working in benched excavations and that safety protocols are in place to respond to emergencies.

By incorporating these detailed design requirements and considerations, you can ensure that your benching system in excavation is not only compliant with regulations but is also optimally safe and effective.

Conclusion

Benching in excavation is an indispensable safety technique that involves creating horizontal steps or levels within the sides of an excavation site, which mitigates the risk of wall cave-ins. This practice is critical for safeguarding the workforce and ensuring the excavation’s structural soundness.

The design requirements for benching are multifaceted, encompassing the assessment of excavation size and shape, soil types, weight considerations, equipment availability, adherence to local regulations, and addressing environmental factors. Thorough planning, informed decision-making, and vigilant execution in benching design are imperative to ensure excavation projects’ successful and safe completion.