Short answer: No—a standard carbon monoxide (CO) detector cannot reliably detect propane leaks. They are designed for two different gases and use different sensing technologies. However, there are combined or multi-gas detectors that include sensors for propane (or more broadly flammable/combustible gases) in addition to CO.

In this article, we’ll explore:

- The nature of carbon monoxide vs. propane (properties, behavior).

- How CO detectors work (technologies, limits).

- Why a CO detector doesn’t pick up propane.

- What kinds of detectors do detect propane or other flammable gases.

- Practical recommendations for safety, installation, and best practices.

CO vs. Propane: Differences in Gas Properties & Hazards

To understand why CO detectors don’t “see” propane, we must understand how the two gases differ.

Carbon Monoxide (CO)

- Chemical nature: CO is a diatomic molecule (CO). It is a toxic gas produced when carbon-containing fuels burn incompletely (e.g. in furnaces, stoves, vehicles).

- Behavior: It is colorless, odorless, and typically mixes fairly evenly with air (its molecular weight is close to that of air).

- Hazard: CO is dangerous because it binds to hemoglobin in the bloodstream, reducing oxygen transport, which leads to poisoning.

- Detection goal: Detect low concentrations before they accumulate to dangerous levels.

Propane (C₃H₈)

- Chemical nature: Propane is a hydrocarbon, a combustible gas used as a fuel (often with LPG systems).

- Behavior: Propane is heavier than air (i.e. denser than ambient air), so leaks tend to accumulate near the floor or low spots.

- Hazard: The main dangers are (a) fire or explosion in the presence of an ignition source, (b) asphyxiation in confined spaces when it displaces oxygen, and (c) dizziness or other symptoms in high concentrations.

- Detection goal: Detect when concentrations approach flammable or dangerous levels, and alert before ignition or suffocation risks.

Because these gases differ in chemical structure, behavior, and hazard mechanism, they require different sensing approaches.

How Carbon Monoxide Detectors Work

Carbon monoxide detectors (or CO alarms) are built to sense CO, not hydrocarbons. Below is a summary of common CO sensing technologies and how they operate.

Standard Sensor Types in CO Alarms

Electrochemical sensors

- The most common in modern, high-quality CO detectors.

- CO enters a cell and is oxidized at an electrode, producing a small current proportional to CO concentration.

- Advantages: good sensitivity, low power, selectivity.

Biomimetic (gel or chemical color change)

- A gel or pad changes color in the presence of CO (inspired by how hemoglobin darkens).

- Some versions integrate optics to detect color change and trigger an alarm.

Semiconductor (metal oxide) sensors

- A heated semiconductor (e.g. tin dioxide) changes its electrical resistance in the presence of CO.

- Simpler, but less selective and may suffer cross-sensitivities or drift.

These sensors are designed and calibrated to respond to CO in the parts-per-million (ppm) range, not to hydrocarbons like propane.

Alarm Logic (Concentration-Time Response)

CO detectors generally use a concentration-time curve approach: i.e. lower CO levels must persist longer to trigger an alarm, while high levels trigger quickly. This prevents nuisance alarms from brief CO spikes.

Because of this, the sensor and electronics expect to see the chemical signature of CO, not other gases.

Limitations & Interferences

- They are not designed to detect combustible gases (like propane, methane, etc.).

- Some combination detectors (discussed later) incorporate additional sensor elements.

- If a CO detector is exposed to other gases or vapors outside its design range, it typically will not respond, or may yield false readings.

As Wikipedia notes, “Carbon monoxide detectors will not detect explosive mixtures; thus the device is often recommended to complement the CO detector.”

Why a CO Detector Does Not Detect Propane

Given the above, here are the key reasons:

- Different gas chemistry: CO is not a hydrocarbon; propane is. The sensors and electronics in CO detectors respond to CO specifically—propane does not produce the same chemical reaction or electrical signal in those sensors.

- Lack of cross-sensitivity or calibration: CO detectors are calibrated to a narrow target gas. They do not include the catalytic, infrared, or pellistor elements needed to sense hydrocarbons (unless explicitly added).

- Gas concentration and detection thresholds: Propane leaks are often detected when reaching a certain fraction of the Lower Explosive Limit (LEL). CO detectors do not have the necessary sensitivity or design to detect hydrocarbon gases at those levels.

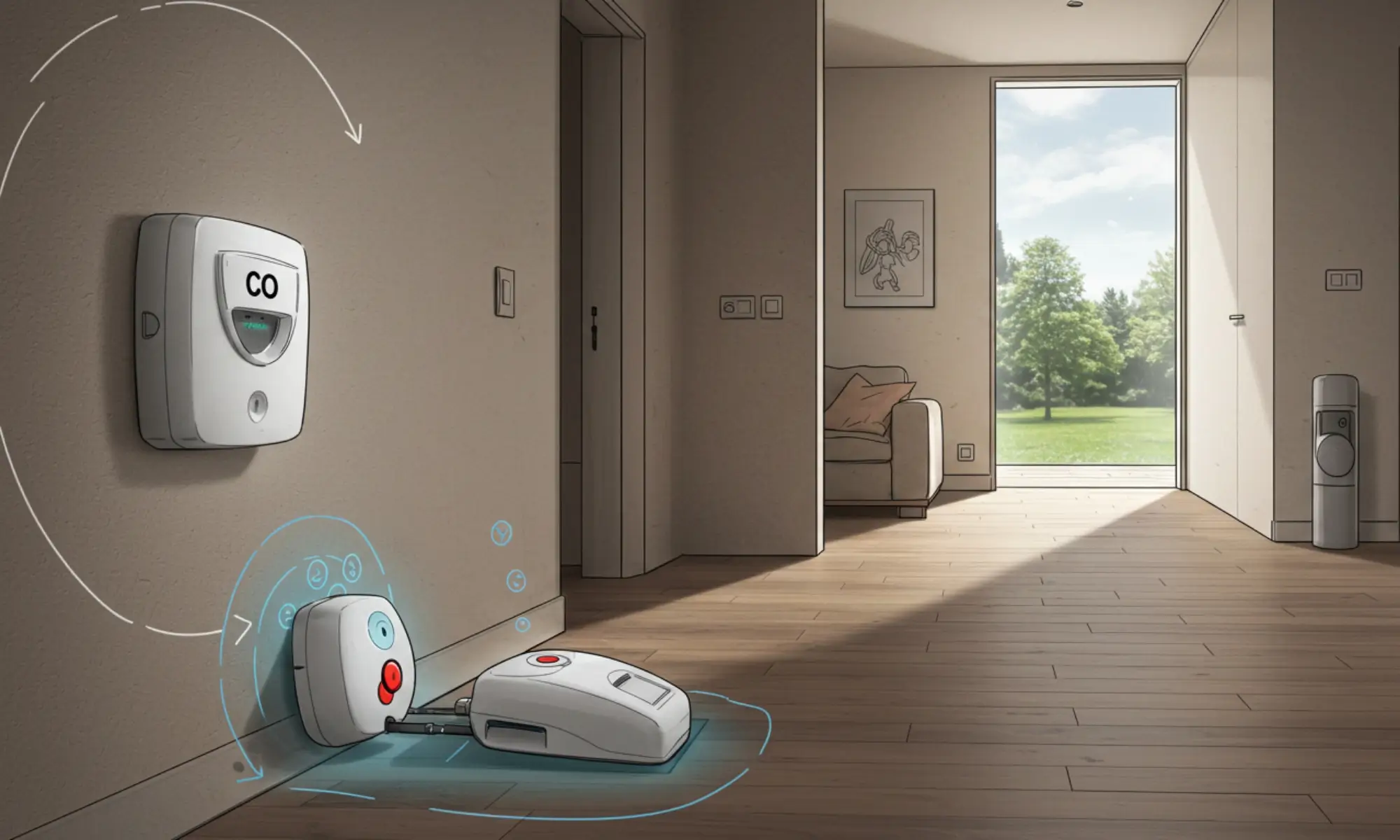

- Physical placement mismatch: Because propane is heavier than air, a proper detector would ideally be placed low (near floor level), whereas CO detectors are often mounted at breathing height or mid-wall. Even if a CO detector somehow responded to propane, its placement would be suboptimal for detecting propane accumulation.

- Manufacturer and safety standards: CO detectors are certified to standards (for example UL 2034) for CO detection, not for combustible gas detection. They are tested for CO performance—not for propane detection ability.

Some combination detectors are marketed with separate sensing modules for propane and CO, but that does not mean a plain CO detector has that capability.

As a practical commentary, many safety organizations and experts consistently state that carbon monoxide detectors cannot detect gas leaks (like propane). You need a separate propane (or combustible gas) detector.

A source from a propane supplier states:

“Despite what you may have heard elsewhere, propane leaks cannot be detected by carbon monoxide detectors. This is why you need both propane leak and carbon monoxide detectors.”

Another guide states absolutely: “No! Carbon monoxide detectors are made to detect carbon monoxide gas. They are not equipped to detect propane.”

Therefore, you cannot rely on a CO detector for propane safety.

Detectors That Can Sense Propane (and Other Combustible Gases)

Because CO detectors are inadequate for propane, one must use the correct device type: combustible/flammable gas detectors, or explosive gas detectors, or multi-gas detectors. Below is a breakdown of relevant types and their technologies.

Types of Gas Detectors for Propane / Hydrocarbons

A. Catalytic Bead (Pellistor) Sensors

- One of the oldest and common methods for detecting combustible gases (including propane, methane).

- Principle: a bead coated with catalyst oxidizes the gas, producing heat, which changes resistance relative to a reference bead.

- Detects gases at a percentage of the Lower Explosive Limit (LEL).

- Widely used in industrial settings.

B. Infrared (IR / NDIR) Sensors

- Based on absorption of infrared wavelengths specific to hydrocarbon bonds.

- More selective (less interference), suitable for some hydrocarbon gases.

- Useful especially in low-oxygen environments or where catalytic sensors may degrade.

C. MEMS / Micro-electromechanical Sensors & Thermal Sensors

- More advanced, miniature sensors that detect changes in thermal conductivity or other thermally mediated effects when a gas is present.

- May categorize gases (e.g., hydrogen, light hydrocarbon, heavy hydrocarbon).

D. Ultrasonic Gas Leak Detectors

- Detect the sound produced by escaping gas under pressure.

- Do not rely on gas diffusion to reach the sensor.

- Good for early detection of leaks in pressurized pipe systems.

E. Multi-Gas or 4-Gas Detectors

- Designed to sense multiple hazardous gases simultaneously (for instance, O₂, CO, H₂S, and combustible gases such as propane or methane).

- The “combustible gas” channel in such devices can often detect propane.

Combined CO + Explosive Gas Alarms

These are consumer-level devices that include both a CO sensor and a combustible gas sensor. For example:

- First Alert GCO1 / GCO1CN: A combination explosive gas + CO alarm that detects propane (and methane) in addition to CO.

- Kidde Firex Plug-In Explosive Gas + CO Detector: marketed to detect CO and combustible gases including propane/natural gas.

In these devices, the combustible gas sensor is a separate element (often catalytic or semiconductor) from the CO sensor. The device will generally have separate thresholds or alarm logic for each gas.

Thus, while a plain CO detector doesn’t detect propane, you can get a combined or dual-function detector that has propane detection capability.

Best Practices, Placement, & Safety Recommendations

Because different gases behave differently (density, mixing behavior, ignition risk), detectors must be installed and maintained correctly.

Placement Guidelines

| Gas Type | Gas Behavior | Ideal Detector Placement |

|---|---|---|

| Propane / heavier-than-air gases | Accumulate low | Place detectors high (near ceiling or upper wall) |

| Natural gas / methane (lighter than air) | Accumulate high | place detectors high (near ceiling or upper wall) |

| Carbon monoxide | Mixes fairly uniformly | Around breathing zone (head- or knee-height), not too high or too low |

Some considerations:

- Don’t place combustible gas detectors too high; the gas may pool beneath before reaching them.

- Avoid installing detectors right next to appliances—they may produce harmless emissions or heat that cause nuisance alarms.

- Ensure ventilation patterns are considered (airflow, drafts).

- For combination detectors (CO + gas), follow manufacturer instructions regarding vertical placement to balance both detection types.

Maintenance & Testing

- Test detectors monthly (if the design allows).

- Replace detectors per manufacturer recommendations (commonly every 5–10 years for sensor lifespan).

- Keep detectors clean, free of dust or paint.

- Don’t install detectors near drafts, vents, fans, or dead air zones.

- Ensure power and backup battery health.

Redundancy & Separate Detectors

Many professionals recommend using separate detectors: one for CO, and another for combustible gas (like propane). This ensures optimal placement and sensitivity tuned to each hazard.

A user discussion in an RV community noted:

“I think you should have both a propane detector and a carbon monoxide detector installed… propane is heavier than air … CO is slightly lighter than air … both gases are a serious health risk.”

This sentiment is echoed by many safety guides.

What to Do in Case of Propane Leak or CO Alarm

- If a propane detector alarms: do not operate electrical switches or appliances, evacuate immediately, call professionals to inspect and repair.

- If a CO detector alarms: also evacuate, get fresh air, turn off fuel-burning appliances (if safe), have qualified technicians check exhausts/venting and appliances.

You cannot rely on a CO detector to warn you of propane leaks, so using both types of detection is crucial to comprehensive safety.

Conclusion & Summary

- A conventional carbon monoxide detector is not designed to detect propane leaks; the gas chemistries and sensing mechanisms differ.

- CO detectors are tuned to sense CO in the ppm range and use electrochemical, biomimetic, or semiconductor sensors specialized for CO.

- Propane (a hydrocarbon) is best detected by combustible gas / explosive gas detectors (catalytic, IR, MEMS, etc.).

- Combined CO + propane detectors exist—they include separate sensors for each gas.

- For best safety, install dedicated propane (or combustible gas) detectors low in the room, and CO detectors near breathing zones, and regularly maintain both.