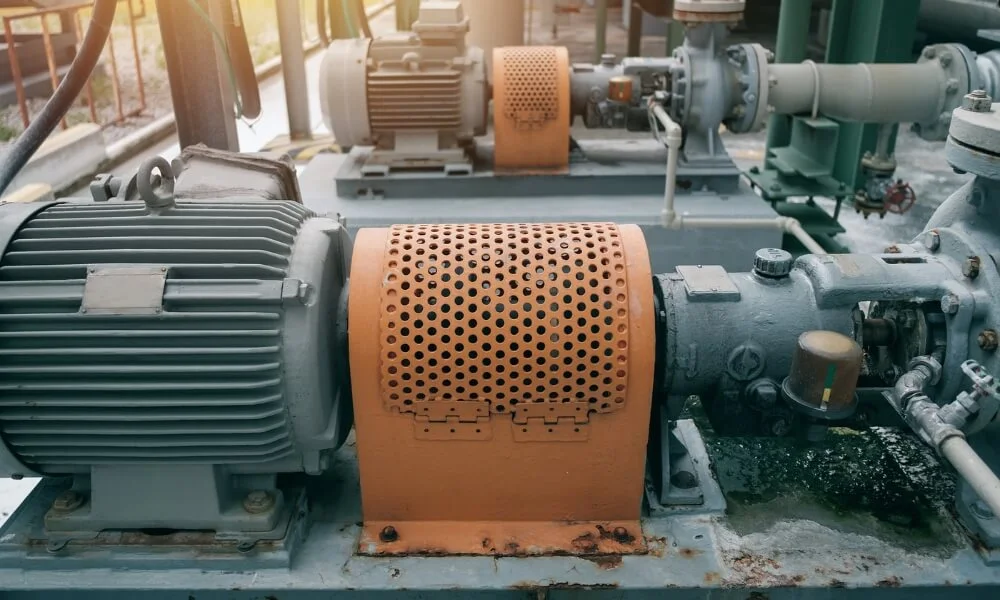

In the intricate world of manufacturing and industrial environments, machines are the lifeblood that keeps production flowing. But with their power and efficiency comes the potential for danger. Moving parts, high temperatures, noise, flying debris, and more can pose significant worker risks. To mitigate these hazards and ensure the safety of everyone on the factory floor, a crucial component comes into play: Machine Guarding.

Machine guarding is the silent guardian of industrial safety, often overlooked yet essential. From the spinning gears of a milling machine to the relentless motion of an assembly line, these protective barriers serve a noble purpose – protecting the workforce from harm, ensuring smooth operations, and fostering a safety culture.

Despite its importance, the value of machine guarding is often underestimated or misunderstood. So, in this blog, we’ll delve deep into the critical role of machine guarding, its benefits, and why it is a non-negotiable aspect of a safe and productive workplace. Whether you’re a seasoned professional, a safety officer, a machine operator, or someone new to the industry, this comprehensive guide will illuminate the importance of machine guarding in keeping operations running smoothly and safely. Buckle up as we journey into machine safety, and explore how guarding acts as the shield against unforeseen machine-related accidents.

Importance Of Machine Guarding

Machine guarding is essential to maintaining a safe working environment, especially in manufacturing and industrial settings. Here are several reasons why it’s crucial:

- Prevention of Accidents: The primary purpose of machine guarding is to prevent accidents that can lead to injuries or fatalities. These can occur when workers come into contact with moving parts, pinch points, flying debris, sparks, or other machinery-related hazards.

- Compliance with Regulations: Various governing bodies worldwide have established rules and regulations regarding machine guarding to promote workplace safety. Businesses must comply with these regulations or face penalties, including fines and legal action.

- Protection from Machinery Malfunctions: Machine guards protect workers from routine operations and machinery malfunctions. For instance, if a part breaks or a machine fails, the guard can help contain the damage and prevent injury.

- Increased Productivity: Workers who feel safe will likely be more productive. With appropriate machine guarding, workers can focus on their tasks without worrying about potential hazards.

- Prevention of Long-Term Health Issues: Long-term exposure to certain types of machinery can lead to chronic health conditions, such as hearing loss from loud noise or repetitive strain injuries. Machine guards can help mitigate these risks.

- Financial Implications: Accidents can lead to significant financial implications for a business, including the cost of medical treatment, workers’ compensation claims, increased insurance premiums, and potential lawsuits. Machine guarding can also reduce these financial risks by reducing the likelihood of accidents.

- Reducing Unplanned Downtime: Accidents can cause unexpected downtime, slowing or halting production entirely. This downtime can lead to significant financial losses, missed deadlines, and other logistical challenges. Machine guards can help prevent such accidents, thus reducing unplanned downtime.

- Protecting Equipment: In some instances, machine guards can also protect the equipment from damage. For example, guards can prevent foreign objects from entering the machinery, which could otherwise cause malfunctions or wear and tear.

- Improving Quality Control: An unexpected machine malfunction can cause quality issues in manufactured products. By helping prevent such malfunctions, machine guards can indirectly contribute to improved quality control.

- Enhancing Company Reputation: A company that takes safety seriously and invests in proper machine guarding demonstrates a commitment to its employees’ well-being. This can enhance the company’s reputation, making it more appealing to potential employees, customers, and business partners.

- Preserving Morale and Productivity: Frequent accidents can lead to a decrease in employee morale and productivity. Workers may become fearful or anxious, leading to mistakes, slower work pace, or resignations. By helping prevent accidents, machine guarding can help maintain high morale and productivity.

- Environmental Protection: Some machine guards are designed to contain leaks or spills that could otherwise harm the environment. For example, guards on chemical processing equipment can prevent harmful substances from escaping.

- Reducing Noise Pollution: Some machines generate high noise levels when in operation. Machine guards can sometimes help to dampen this noise, providing a more comfortable and safer working environment for employees.

- Liability Protection: In an accident, if an investigation finds that the company was neglectful in implementing necessary safety measures such as machine guarding, the company could be held legally liable for damages. Proper machine guarding can help protect the company from such liability.

- Insurance Premiums: Adequate safety measures, including machine guarding, can positively impact the cost of insurance premiums. Insurance companies may offer lower premiums to companies that have robust safety measures in place, as it reduces the likelihood of accidents and claims.

Machine guards must be appropriately designed, installed, and maintained to ensure effectiveness. They should not create additional hazards (like sharp edges) and must allow workers to perform their jobs without difficulty. Training employees about the correct use and respect for machine guards is also crucial.

In conclusion, machine guarding is indispensable in industrial safety, creating a secure environment for workers while enhancing productivity and adherence to regulatory standards. It functions as a physical barrier against machinery-related accidents and a symbol of a company’s commitment to employee well-being and quality control. Despite technological advancements, the human element in manufacturing remains irreplaceable, and hence, protecting it through effective machine-guarding strategies should remain a paramount concern. As we continue to push the boundaries of industrial capabilities, ensuring safety remains an integral part of our journey because a safe workplace is the foundation of a successful business.