In our rapidly evolving industrial and technological landscape, safety remains paramount. One of the unsung heroes in ensuring our safety, especially in environments prone to gas-related hazards, is the gas detector. These devices, often overlooked, play a pivotal role in safeguarding both human lives and the environment.

In this guide, we will delve deep into the world of gas detectors, shedding light on their significance, diverse applications, the various types available, and the science behind their operation. Whether you’re a professional in an industry that relies on these tools or simply a curious individual, this comprehensive overview will equip you with essential knowledge about these life-saving devices. Join us as we explore the intricacies of gas detectors and their indispensable role in our modern world.

What are Gas Detectors?

Gas detectors are devices that detect the presence of gases in an area, often as part of a safety system. They are used to detect leaks of hazardous gases and to ensure that the air in a particular environment is safe to breathe. These devices work by sensing different gases in the environment and producing a signal, usually an alarm when the levels of a particular gas exceed a certain threshold.

Importance of Gas Detectors

- Safety: Many gases, such as carbon monoxide, natural gas, and many industrial gases, are invisible and odorless, making them difficult to detect without specialized equipment. A gas leak can lead to explosions, fires, or asphyxiation, making gas detectors crucial for ensuring safety in various settings.

- Health Protection: Prolonged exposure to certain gases can have detrimental health effects. For instance, inhaling carbon monoxide can lead to poisoning, as it prevents oxygen from entering the body’s cells and tissues. Gas detectors can alert individuals to harmful levels of gas before they become a health risk.

- Environmental Protection: Some gases, when released into the atmosphere, can contribute to environmental issues like air pollution or the greenhouse effect. Detecting and mitigating these gas leaks can help in reducing environmental damage.

- Economic Reasons: In industrial settings, gas leaks can result in the loss of valuable resources. Detecting leaks early can save money by preventing wastage.

In summary, gas detectors play a vital role in ensuring the safety, health, and well-being of individuals and the environment, making them indispensable in many sectors and situations.

Different Uses Of Gas Detectors

Gas detectors play a crucial role in various industries and settings to ensure safety, compliance, and operational efficiency. Here are some of the primary uses of gas detectors:

- Industrial Safety: In manufacturing plants, refineries, and chemical processing facilities, gas detectors monitor for leaks of combustible or toxic gases. Early detection can prevent explosions, fires, and exposure to harmful substances.

- Mining: Underground mines can accumulate dangerous gases like methane, carbon monoxide, and hydrogen sulfide. Gas detectors help ensure the safety of miners by alerting them to hazardous gas concentrations.

- Oil and Gas Industry: In drilling and production operations, gas detectors monitor for hydrocarbon leaks and other hazardous gases to prevent explosions and protect workers.

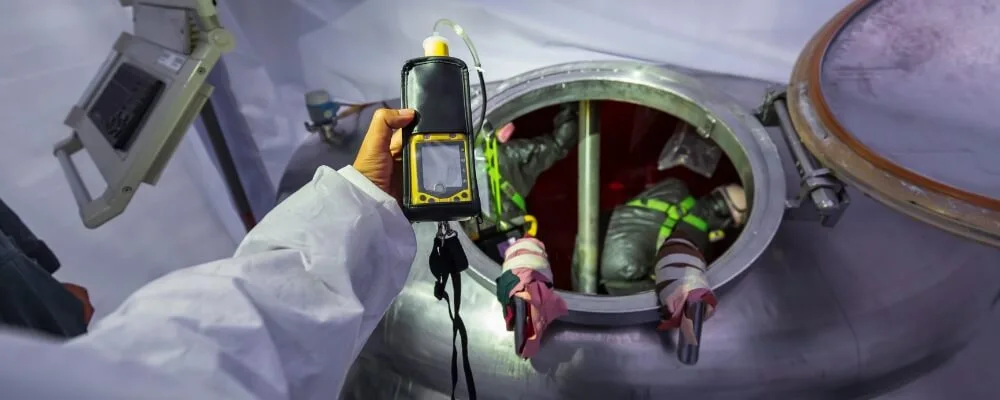

- Confined Space Entry: Before entering tanks, vessels, or other confined spaces, workers use portable gas detectors to check for the presence of toxic or combustible gases.

- Firefighting: Firefighters use gas detectors to identify the presence of combustible gases in fire scenes and to check for carbon monoxide after a fire has been extinguished.

- Environmental Monitoring: Gas detectors are used to monitor air quality, detect pollutants, and ensure compliance with environmental regulations.

- Home Safety: Residential gas detectors can alert homeowners to dangerous levels of carbon monoxide, natural gas, or propane leaks, helping to prevent poisoning or explosions.

- Research Laboratories: In labs, gas detectors ensure that harmful gases, often used or produced in experiments, don’t reach dangerous levels.

- Food and Beverage Industry: Gas detectors monitor for leaks of refrigerant gases in cold storage facilities or carbon dioxide in beverage production.

- Waste Management: In waste treatment plants, gas detectors monitor for methane and other hazardous gases that can be produced during the decomposition of organic materials.

Types Of Gas Detectors and How Do They Work

Gas detectors come in various types, each designed to detect specific gases or serve particular environments. Here are some of the primary types of gas detectors:

1. Catalytic Bead Sensors

Catalytic bead sensors are primarily designed to detect combustible gases. The core component of this sensor is a bead coated with a catalyst that promotes the oxidation of combustible gases. When the target gas comes into contact with this bead, it undergoes oxidation, producing heat. This heat causes a change in the electrical resistance of the bead.

By measuring this change, the sensor can determine the concentration of the combustible gas present. The reliability and simplicity of catalytic bead sensors have made them a staple in many industrial applications.

2. Infrared (IR) Detectors

Infrared detectors operate on the principle that certain gases absorb infrared radiation at specific wavelengths. The detector emits an infrared light through a sample of air, and a sensor on the other side measures the amount of light received.

If there are gases like carbon dioxide or hydrocarbons present, they will absorb some of the infrared light, causing a reduction in the light received by the sensor. By analyzing this reduction, the concentration of the gas can be determined.

3. Photoionization Detectors (PIDs)

PIDs are highly sensitive devices that utilize ultraviolet light to ionize gases. When UV light interacts with certain molecules, it can eject electrons from them, creating ions. The resulting electric current from these ions is proportional to the concentration of the gas.

PIDs are especially effective for detecting volatile organic compounds (VOCs), which are often found in paints, solvents, and some industrial processes.

4. Electrochemical Sensors

These sensors function by initiating an electrochemical reaction that occurs when a specific gas interacts with certain reactive substances on an electrode. For instance, when carbon monoxide comes into contact with the electrode, it gets oxidized, producing an electric current.

The magnitude of this current is directly related to the concentration of the gas, allowing for precise measurements. Electrochemical sensors are favored for their selectivity and sensitivity to gases like carbon monoxide, chlorine, and nitrogen dioxide.

5. Metal Oxide Semiconductors (MOS)

MOS sensors contain a film of metal oxide on a semiconductor layer. When exposed to certain gases, such as hydrogen sulfide, the resistance of this film changes. By monitoring this resistance change, the sensor can determine the concentration of the target gas. These sensors are known for their durability and long lifespan.

6. Ultrasonic Detectors

Rather than detecting the gas molecules themselves, ultrasonic detectors pick up on the sound waves generated by a gas leak, especially in high-pressure systems. These sound waves are distinct from typical background noises, allowing the detector to alert users to even minor leaks.

7. Tunable Diode Laser Spectroscopy (TDLAS)

TDLAS is a sophisticated technique that employs a tunable diode laser to analyze gas concentrations. The laser emits light at specific wavelengths, which certain gas molecules absorb. When the laser light passes through a gas sample, the molecules of the target gas absorb some of the light.

By measuring the intensity of the light before and after it passes through the sample, the concentration of the gas can be determined. TDLAS offers high sensitivity and selectivity, making it suitable for applications that require precise gas concentration measurements.

8. Colorimetric Gas Detection Tubes

These tubes are a manual method of detecting specific gases. Each tube is filled with a chemical reagent that reacts with a particular gas, resulting in a color change. The user exposes the tube to the air for a specified time, and if the target gas is present, the reagent changes color.

The length of the color stain inside the tube corresponds to the concentration of the gas. While they are not as sophisticated as some other methods, they offer a simple and direct way to detect certain gases in the field.

9. Open Path Detectors

Open path detectors are designed to monitor gas concentrations over large areas or distances. They work by emitting an infrared beam from a source to a detector positioned some distance away. If a gas cloud passes between the source and the detector, it will absorb some of the infrared light.

By analyzing the reduction in light intensity, the system can determine the presence and concentration of the gas. This type of detector is especially useful for perimeter monitoring in large industrial complexes or for detecting gas plumes.

10. Flame Ionization Detectors (FIDs)

FIDs are primarily used to measure the concentration of hydrocarbons in the air. The principle behind FIDs is the ionization of gas molecules when they are burned in a flame. As the hydrocarbons burn, they produce ions.

An electrode system within the FID measures the current produced by these ions, which is proportional to the concentration of hydrocarbons in the sample. FIDs are commonly employed in gas chromatography and environmental monitoring due to their high sensitivity to organic compounds.

In essence, each type of gas detector offers unique advantages tailored to specific applications and gases. The choice of detector often depends on the nature of the environment, the specific gases of concern, and the required sensitivity and accuracy of the measurements.

Each type of gas detector has its advantages and limitations, making it essential to choose the right detector based on the specific application and the gases that need to be detected.

Conclusion

As we navigate through the complexities of modern industries and daily life, the significance of gas detectors becomes increasingly evident. These devices, though often operating silently in the background, stand as vigilant guardians, ensuring our safety against potential gas-related hazards. From the depths of mining operations to the confines of our homes, they offer an essential line of defense against potential catastrophes.

By understanding their importance, diverse applications, and the science behind their functionality, we can better appreciate and utilize these tools to their fullest potential. In a world where safety and technological advancements go hand in hand, gas detectors undeniably hold a pivotal position, reminding us that innovation, when directed towards the well-being of all, can truly make a difference.