In electrical tools, ensuring user safety is a non-negotiable priority. One of the critical safety features integral to many electrical appliances and power tools is double insulation. In this insightful article, we will embark on an exploratory journey to understand what double insulation entails, the significance of its symbol, and the plethora of safety benefits it bestows upon users.

From the casual DIY enthusiast to the seasoned professional, double-insulated tools play a crucial role in safeguarding against electrical hazards. This comprehensive guide is an essential resource for anyone seeking to enhance their knowledge and appreciation of the importance of double insulation in tools. Let the exploration begin.

What is Double Insulation?

Double insulation is a safety feature used in electrical appliances and tools to provide protection against electric shock. It involves insulating the appliance’s live parts so the user is not exposed to electrical currents, even if the basic insulation fails.

In simpler terms, double insulation comprises two layers:

- Basic Insulation: The first layer is the basic insulation that separates the conductive parts of the appliance from the user. This is typically achieved through materials like plastic or rubber that don’t conduct electricity.

- Additional Insulation: The second layer is the additional insulation, which acts as an extra protective barrier in case the basic insulation fails. This may include an extra casing or protective shell around the appliance made from non-conductive materials.

One thing to note is that double-insulated appliances typically do not have an earth wire. This is because the double insulation is designed to be so effective that even if a fault occurs, it is extremely unlikely that the appliance could become live and pose a risk of electric shock. The symbol for double insulation is a square within a square, and you can often find it on the labeling of electrical appliances.

Double insulation is especially important in portable tools and appliances that are likely to be handled frequently or used in environments where the risk of damage or exposure to water might be higher. It’s an essential aspect of electrical safety, helping to protect users from the dangers of electric shock.

Double Insulated Tools

Double-insulated tools are electrical tools designed with an extra insulation layer to protect the user from electric shock. These tools are primarily used for enhanced safety, especially in environments with a higher risk of electrical accidents. Here are a few key points about double-insulated tools:

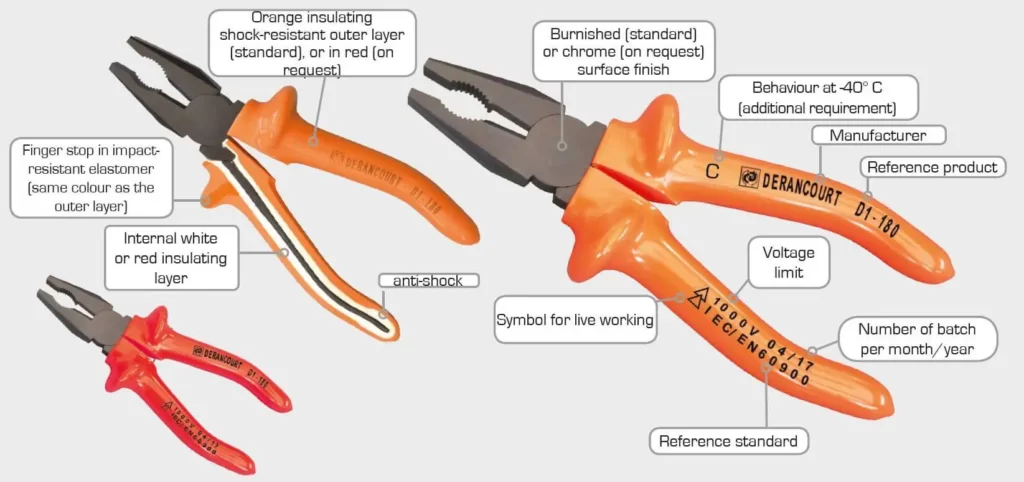

- Structure: Double-insulated tools are constructed with two layers of electrical insulation. The first layer isolates the internal electrical components from the outer casing of the tool, and the second layer acts as additional protection in case the first layer fails. The casing of these tools is generally made of non-conductive materials like plastic.

- Earthing is Not Required: As I mentioned earlier, one characteristic of double-insulated tools is that they don’t have an earth connection. This is because the double insulation is supposed to be so robust that even if a failure occurs, it’s highly unlikely that the tool could become life and pose a risk of electric shock.

- Identification: You can identify a double insulated tool by the double square symbol (a square within a square) on its label. This symbol indicates that the tool complies with safety regulations regarding double insulation. The label might also contain the words “Double Insulated” or “Double Insulation.”

- Uses: Double-insulated tools are used where there’s a higher risk of electrical accidents due to environmental conditions or the nature of the work. They are especially useful when grounding isn’t practical or in damp conditions with high risk of electrical shock. Examples include drills, saws, hairdryers, and many other electrical appliances and tools.

- Maintenance: Double-insulated tools require proper care and maintenance. Since their safety relies on the integrity of their insulation, it’s critical to regularly inspect them for cracks, damages, or any signs that the insulation might be compromised. Adhering to power tools safety rules is essential to keeping these tools functioning safely and effectively.

- Regulations: Double insulation in tools is often a requirement under various national and international safety standards and regulations, which aim to ensure that electrical tools are safe to use in different working conditions.

- Considerations: Although double-insulated tools are designed for safety, using them cautiously is still essential. Users should follow the manufacturer’s instructions and safety guidelines, wear appropriate protective gear, and be aware of the surrounding environment where the tool is used.

Double Insulated Tools Examples

Double-insulated tools are popular in professional and household settings for their added safety. Here are some examples of double-insulated tools:

- Electric Drills: Used for drilling holes in various materials. The double insulation ensures that if the user accidentally drills into a live wire or if there’s an internal fault, they are protected from electric shock.

- Handheld Circular Saws: Commonly used in woodworking and carpentry. Double insulation provides an added safety level, especially considering these tools are often used in close contact with the user’s body.

- Jigsaws: Used for cutting irregular curves in wood, metal, or other materials. The double insulation is particularly helpful when working with materials that could conduct electricity.

- Reciprocating Saws: Often used in demolition or construction for cutting through materials quickly. Double insulation is important as these tools can be used in environments where electrical wiring may be exposed.

- Angle Grinders: Used for grinding, cutting, and polishing materials like metal and stone. Double insulation is essential as sparks and debris can damage the internal wiring.

- Electric Sanders: Including belt sanders, random orbit sanders, and palm sanders, which are used for smoothing surfaces. Double insulation is beneficial because the tool is often in close contact with the user’s hands.

- Hair Dryers: Common household appliances are often double-insulated to protect the user from electric shock, especially when used near water.

- Blenders and Food Processors: Kitchen appliances often include double insulation to ensure users’ safety, considering that they are used in a kitchen environment where spills and splashes are common.

- Electric Can Openers: These are often used in kitchens and may come into contact with liquids, so double insulation is important for safety.

- Electric Trimmers and Hedge Cutters: These tools are often exposed to the outdoors in garden maintenance, and double insulation helps protect the user from electric shocks due to damp conditions or accidental cutting of the power cord.

Remember that proper use and maintenance are key to ensuring the safety of any double-insulated electrical tool. Always read and follow the manufacturer’s instructions and safety guidelines.

Double Insulated Symbol

The double-insulated symbol is a simple icon representing the concept of double insulation in electrical appliances and tools. This symbol comprises two concentric squares—a square within a square.

This symbol on an electrical appliance or tool indicates that the device has been designed with double insulation for enhanced safety. It has two layers of insulation to protect the user from electric shock. It doesn’t require an earth connection. Manufacturers use this symbol to comply with various international safety standards and regulations. It assures the consumer that the product has been designed with user safety, especially regarding electrical insulation.

Always look for this symbol, especially if you work in conditions with a higher risk of electric shock or if grounding is not practical or possible.

How Double-Insulated Tools Help Protect Against Shock

Double-insulated tools are specifically designed to provide extra protection against electric shock. Here’s how they accomplish this:

- Non-Conductive Casing: The outer casing or housing of double-insulated tools is made from non-conductive materials such as plastic or reinforced polymers. This prevents any live electrical parts from coming into contact with the user.

- Additional Insulation Layer: Inside the tool is an extra insulation layer in addition to the normal insulation around the wires and electrical components. This secondary insulation is crucial because, if the primary insulation were to fail, the secondary insulation acts as a backup to prevent the electrical current from reaching the outer casing of the tool.

- Absence of Earth Connection: Double-insulated tools don’t have an earth wire, which in other tools is meant to provide a path for excess current to flow safely into the ground in case of a fault. Because double insulation is so effective at containing the current within the tool, even if there’s a fault, an earth wire is unnecessary. This is especially useful in situations where grounding is not practical.

- Enhanced Safety in Adverse Conditions: Electric shock risk increases in damp or wet environments. Double-insulated tools are safer to use in such conditions because even if water gets into the tool, the double insulation helps to ensure that the electrical current does not reach the user.

- Protection Against Unexpected Scenarios: In cases where the tool may become damaged or the wiring inside becomes exposed due to unforeseen circumstances, the double insulation helps prevent the electrical current from making a direct path to the user.

- Compliance with Safety Standards: Double-insulated tools must comply with rigorous safety standards, which means they are subjected to various tests to ensure their effectiveness in protecting against electric shock.

However, it is important to remember that while double-insulated tools provide significant protection, they are not invincible. Proper handling, regular inspection for damage, and adherence to safety protocols are critical to ensuring the effectiveness of double insulation in protecting against electric shock.

Conclusion

In conclusion, double-insulated tools are essential to safety protocols in various professional and personal contexts, offering a robust shield against electric shocks. By recognizing the symbol of double insulation—a square within a square—we can readily identify these tools and confidently harness their safety advantages. Beyond mere compliance with safety regulations, double insulation is a testament to the industry’s commitment to prioritizing user safety.

It’s an integral part of risk mitigation strategies, particularly in environments with heightened exposure to electrical hazards. Therefore, understanding the mechanics and benefits of double insulation is crucial for anyone regularly using electrical tools, contributing significantly to personal safety and proficiency in task execution.