I was auditing a heavy logistics yard at the Port of Rotterdam during a dense morning fog when I saw a 40-foot flatbed driver step down from his cab into an active straddle carrier lane. He was wearing dark civilian clothes, slip-on shoes, and had no hard hat—completely invisible to the 40-ton container handler approaching just twenty meters away. I blew my emergency air horn and sprinted to physically pull him out of the blind spot seconds before the heavy machinery clipped his position. That near-miss was a chilling reminder that the moment a truck driver kills the engine and steps onto the asphalt, they cease to be just a driver and immediately become a vulnerable pedestrian in a high-hazard industrial zone.

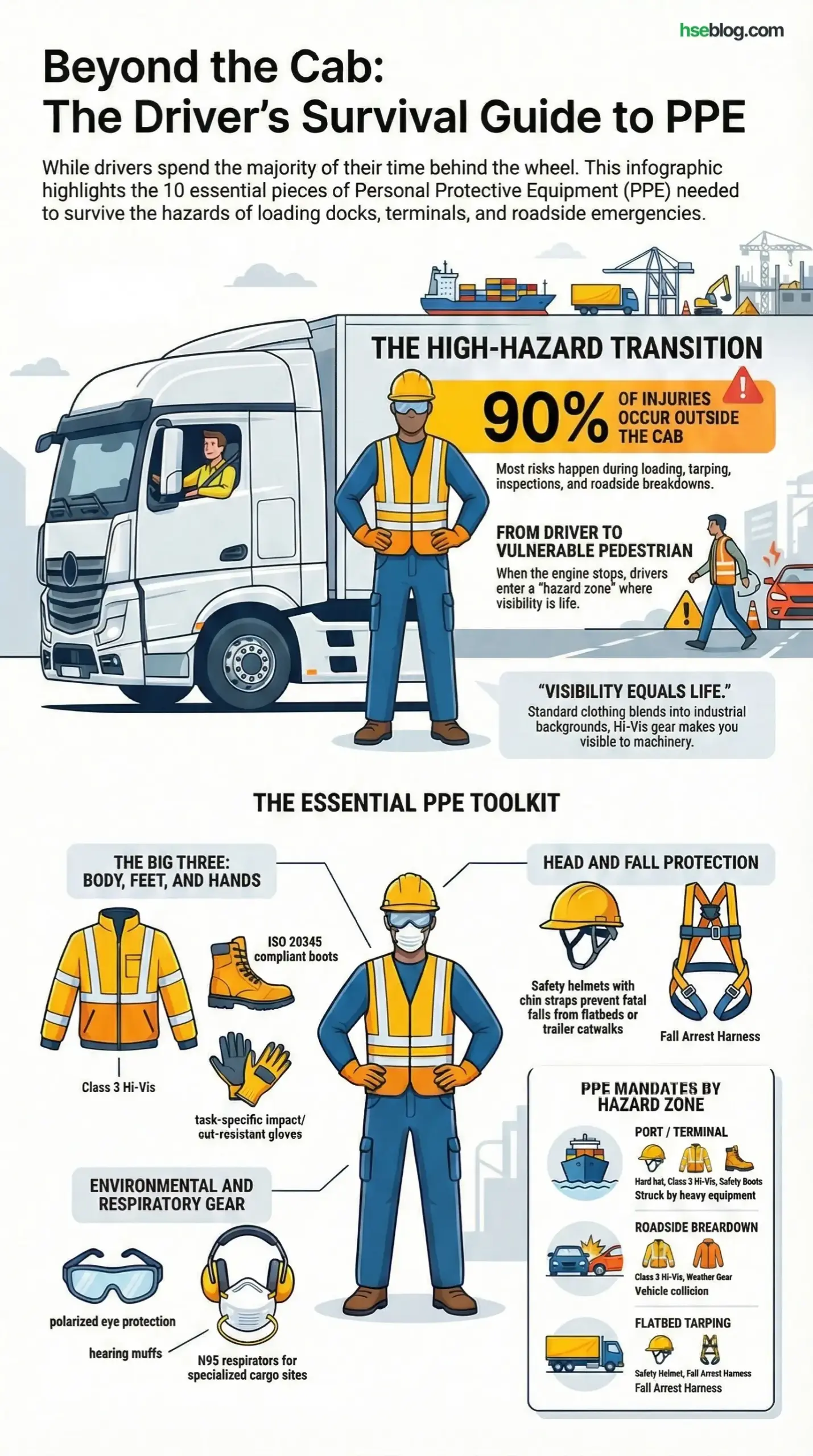

Too many fleet managers and site controllers mistakenly believe a truck driver’s safety starts and ends with a seatbelt and a speed limiter. In reality, drivers are exposed to a chaotic mix of hazards during loading, tarping, pre-trip inspections, and roadside breakdowns, where the hierarchy of controls often fails. This article breaks down the 10 essential Personal Protective Equipment (PPE) items that every professional truck driver must carry, based on compliance standards and the hard lessons I have learned from investigating logistics fatalities and auditing supply chain safety systems.

1. High-Visibility (Hi-Vis) Clothing

In the world of logistics and transport, visibility equals life. Loading docks, distribution centers, and construction sites are chaotic environments where heavy vehicles and pedestrians constantly intersect.

When a driver exits their cab in a dimly lit yard or during a roadside emergency, standard clothing blends into the background. Hi-vis vests or jackets equipped with retro-reflective tape reflect light back to the source, ensuring forklift operators and oncoming traffic can see the driver from a safe distance.

- Class 2 Vests: Suitable for standard yard operations and daytime deliveries.

- Class 3 Jackets: Mandatory for high-speed roadside breakdowns, night work, and adverse weather conditions.

- Flame-Resistant (FR) Hi-Vis: Required for drivers hauling petrochemicals or entering oil and gas facilities.

2. Heavy-Duty Safety Footwear

Slips, trips, and falls represent the highest frequency of recordable injuries among truck drivers. The transition from the steel steps of a truck cab to potentially oily or icy ground is highly hazardous.

Drivers need footwear that provides extreme traction and impact protection. I always mandate ISO 20345 compliant boots for any driver entering our managed sites, as standard sneakers offer zero protection against dropped cargo or rolling forklift tires.

- Slip-Resistant Soles: Essential for walking on wet loading docks, oily terminal floors, and snowy roadside shoulders.

- Steel or Composite Toe Caps: Protect against crushed feet from dropped pallets, chains, and trailer ramps.

- Ankle Support: Prevents severe sprains when jumping down from flatbed trailers.

3. Industrial Work Gloves

A truck driver’s hands are their livelihood, yet hand injuries are incredibly common during coupling, uncoupling, and cargo securement. Pinch points on fifth-wheel release handles and sharp edges on freight cause daily lacerations.

Selecting the right glove depends heavily on the cargo type. A generic cotton glove offers no real protection in heavy logistics; drivers need task-specific hand protection.

- Impact-Resistant Gloves: Vital for drivers chaining down heavy loads or handling landing gear cranks.

- Cut-Resistant (ANSI Cut Level A3-A4): Necessary for handling sharp metal banding or unboxing freight.

- Chemical/Nitrile Gloves: Mandatory for hazmat drivers during loading and discharge operations.

“A truck driver spends 80% of their time driving, but 90% of their injuries occur during the other 20% of the time spent outside the cab.”

4. Hard Hats and Safety Helmets

While a cab protects the head, the loading zone does not. Cranes, overhead doors, and stacked cargo present constant struck-by hazards.

Many modern facilities now strictly enforce a “No Helmet, No Entry” policy for visiting drivers. Traditional hard hats are standard, but the industry is shifting towards climbing-style safety helmets with chin straps, as they do not fall off if a driver trips.

PPE Requirement Matrix for Drivers

| Hazard Zone | Primary Hazard | Mandatory PPE |

| Port / Terminal | Struck by heavy equipment | Hard hat, Class 3 Hi-Vis, Safety Boots |

| Roadside Breakdown | Vehicle collision | Class 3 Hi-Vis, Weather Gear |

| Flatbed Tarping | Fall from height (trailer) | Safety Helmet, Fall Arrest Harness |

| Chemical Plant | Splash / Vapor release | Respirator, Chemical Suit, Face Shield |

5. Protective Eyewear

Eye protection for drivers serves a dual purpose: mitigating road fatigue and preventing impact injuries during exterior tasks. Blowing dust in distribution yards and snapping bungee cords are common culprits for eye injuries.

I recommend drivers carry two types of eye protection. High-quality polarized sunglasses reduce UV exposure and glare on the road, while ANSI Z87.1 certified safety glasses are required for yard work and inspections.

- Polarized Sunglasses: Reduces eye strain and prevents long-term macular degeneration from sun glare.

- Clear Safety Glasses: Essential for pre-trip inspections, looking under chassis, and entering manufacturing floors.

- Face Shields: Required for hazardous liquid transfers (e.g., fuel tankers).

6. Hearing Protection

Prolonged exposure to the low-frequency drone of a diesel engine, air brakes, and the ambient noise of a busy distribution center can lead to irreversible Noise-Induced Hearing Loss (NIHL).

While driving, total noise isolation is unsafe, but during loading and unloading, hearing protection is critical. I frequently cite logistics sites for failing to provide earplug dispensers at driver waiting areas.

- Foam Earplugs: Cost-effective and suitable for high-noise areas like cement plants or stamping facilities.

- Over-the-Ear Earmuffs: Easy to put on and take off for short-duration tasks outside the cab.

7. Fall Protection Gear

Falls from flatbed trailers and bulk tanker catwalks are statistically the most severe non-traffic injuries for drivers. Working at heights of just 1.5 to 4 meters is enough to cause fatal head injuries.

For drivers who must tarp loads or perform top-loading, standard PPE is not enough. They require active fall prevention systems when fixed gantries are not available.

- Full-Body Harness: Used in conjunction with an overhead rigid rail or self-retracting lifeline at loading bays.

- Head Protection with Chin Strap: Ensures the helmet stays on during a fall.

8. Respiratory Protection

Drivers hauling bulk powders, aggregates, or hazardous chemicals face significant inhalation risks. Even general freight drivers encounter heavy diesel particulates and yard dust.

Respiratory protection must be fit-tested to be effective. Relying on simple paper masks during the offloading of cement or hazardous materials is an audit failure I see regularly.

- N95 / FFP2 Respirators: Suitable for dusty environments like quarries and aggregate yards.

- Half-Mask Elastomeric Respirators: Required with specific cartridges for drivers handling fuel, chemicals, or waste.

9. Weather-Specific Protective Gear

Extreme weather turns routine tasks into high-risk operations. A roadside tire change in freezing rain can quickly lead to hypothermia or frostbite.

Drivers must be equipped to survive outside their climate-controlled cabs. PPE in this category is about physiological preservation as much as physical protection.

- Insulated / Thermal Layers: Crucial for cold-weather inspections and preventing hypothermia.

- High-Visibility Rain Gear: Keeps the driver dry while ensuring they remain visible in low-light storm conditions.

- Cooling Vests: Prevents heat stroke for drivers working in extreme desert climates.

10. Ergonomic Supports

Musculoskeletal disorders (MSDs) are rampant in the trucking industry due to prolonged sitting coupled with the sudden heavy lifting of tarps, dunnage, and trailer doors.

While engineering controls like automatic landing gear are best, PPE can bridge the gap. I consider ergonomic gear a proactive measure against long-term disability claims.

- Industrial Knee Pads: Protects the knees during under-carriage inspections and chaining.

- Back Support Belts: Acts as a reminder to maintain proper posture during heavy lifting, though it does not replace good lifting techniques.

Pro Tip: As a site safety manager, I never penalize a driver for forgetting their PPE. Instead, I keep a “loaner locker” at the gatehouse. Safety is about enabling safe work, not trapping people in compliance violations. However, drivers who refuse to wear provided PPE are immediately escorted off the site.

Conclusion

A truck driver’s job is not confined to the highway; it involves navigating some of the most dynamic and hazardous industrial environments in the world. From high-visibility vests that prevent pedestrian impacts to fall protection gear that stops catastrophic drops from flatbeds, each of these 10 PPE items addresses a specific, fatal risk. As HSE professionals and fleet managers, we must shift the culture from viewing PPE as a regulatory burden to recognizing it as essential survival gear.

Ultimately, compliance metrics and on-time delivery percentages mean nothing if a driver does not make it home to their family. Providing, maintaining, and enforcing the use of the right PPE is a fundamental moral obligation to the men and women who keep our supply chains moving.