In the intricate ecosystem of healthcare facilities, certain rooms play an understated yet indispensable role in ensuring cleanliness, safety, and operational efficiency. One such unsung hero is the ‘sluice room.’ Often overshadowed by more prominent facilities like operation theaters or intensive care units, sluice rooms are the backbone of sanitary processes, ensuring that healthcare environments remain sterile and contamination-free.

This comprehensive guide will delve deep into the realm of sluice rooms, from their foundational definition to their environmental considerations. We’ll shed light on their core purpose, explore the various types one might encounter, and inform you of their risks, essentials, and best practices.

Whether you’re a healthcare professional, a facility planner, or simply someone keen to understand the intricacies of healthcare operations, this guide promises to be an enlightening journey through the world of sluice rooms. Let’s embark on this exploration, understanding how such spaces, often unnoticed, play a pivotal role in upholding the gold standard of care in medical establishments.

What is Sluice Room? Definition

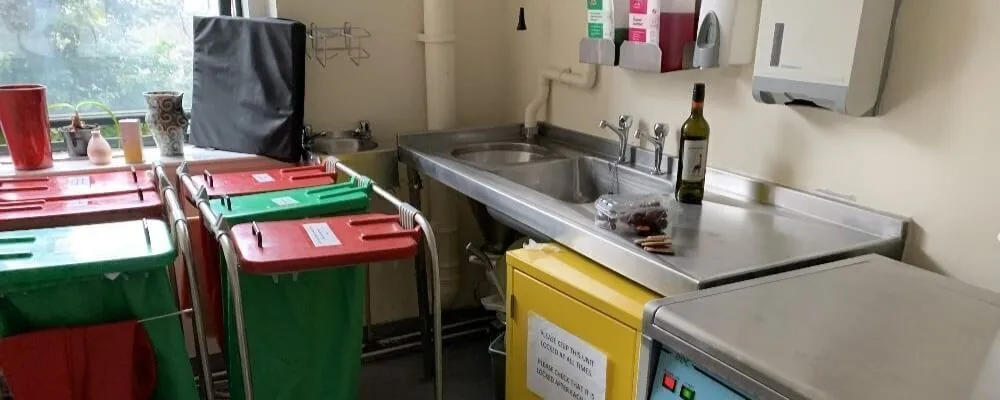

A sluice room is a specialized area within healthcare facilities, such as hospitals and nursing homes, dedicated to disposing of human waste products and disinfection medical items. Often referred to as a dirty utility room, its primary function is to manage and contain potentially infectious waste, ensuring a hygienic environment and minimizing the risk of cross-contamination.

Within the sluice room, contaminated items, ranging from bedpans to surgical instruments, are either disposed of or thoroughly cleaned and disinfected. The room is meticulously designed and equipped with specific apparatus like flusher disinfectors and macerators to handle waste efficiently. This arrangement ensures patient safety and provides healthcare workers with a controlled environment to manage potentially hazardous materials.

The Purpose Of Sluice Room

The purpose of a sluice room is to provide a dedicated, controlled environment within healthcare facilities for the safe disposal of human waste products and the disinfection of medical equipment. Its primary objectives are:

- Infection Control: Human waste can contain pathogens, so the sluice room acts as a containment area, ensuring these potentially infectious materials are separated from the general patient and staff areas. This reduces the risk of cross-contamination and the spread of diseases.

- Efficient Waste Disposal: The room is equipped with specialized equipment, such as flusher disinfectors and macerators, to dispose of waste efficiently and hygienically.

- Cleaning and Disinfection: Besides waste disposal, sluice rooms also provide a space for the thorough cleaning, disinfection, and sometimes sterilization of reusable medical items like bedpans, urine bottles, and other equipment. This ensures that equipment returned to patients is safe and free from harmful microorganisms.

- Safety for Staff: Providing a designated area for these tasks ensures that healthcare staff have a safe and purpose-built environment to handle potentially hazardous materials, reducing their risk of exposure.

- Storage: Sluice rooms often have areas for storing clean and disinfected equipment, ensuring they remain uncontaminated until their next use.

In essence, the sluice room plays a crucial role in maintaining the hygiene standards of healthcare facilities, ensuring patient safety, and protecting healthcare workers from potential hazards.

Different Types of Sluice Rooms

Sluice rooms are essential components in healthcare facilities, ensuring proper waste management and infection control. The type and setup of a sluice room can vary based on the facility’s specific needs, the volume of waste generated, the size of the institution, and regional regulations. Here are the different types of sluice rooms:

- General Sluice Room: Commonly found in hospitals and nursing homes, this type of room is equipped with basic necessities such as flusher disinfectors, macerators, sinks, and storage areas. It caters to in-patients’ regular needs, handling solid and liquid waste.

- Maternity Sluice Room: In maternity wards, these rooms are designed to handle postnatal waste. They might have specialized equipment to deal with items like placenta buckets.

- Isolation Sluice Room: These are attached to isolation wards where patients with highly infectious diseases are housed. The design and equipment in these rooms ensure that waste is handled and disposed of to minimize the risk of disease transmission.

- Pediatric Sluice Room: Located in children’s wards, these rooms may contain smaller equipment or items tailored to pediatric care needs.

- Portable or Mobile Sluice Room: A relatively new concept, these modular units can be quickly set up in emergencies or during outbreaks where rapid response is needed. They are often deployed in field hospitals or disaster zones.

- Specialized Sluice Rooms for Outpatient Procedures: In settings like dialysis centers, where there is a need to handle specific types of waste, specialized sluice rooms might be set up.

- Elderly Care Sluice Room: Often found in long-term care facilities or nursing homes, these rooms might have equipment tailored to the needs of elderly patients, focusing especially on incontinence management.

- Mortuary Sluice Room: Situated in mortuaries or post-mortem rooms, these sluice rooms handle the specific needs related to deceased patients.

Each type of sluice room is designed considering the unique requirements of the attached ward or unit. Despite the differences in equipment or layout, the primary objective remains the same across all sluice rooms: to ensure effective, safe, and hygienic waste disposal, thereby minimizing the risk of infection spread.

Risks Associated With The Sluice Room

While crucial for maintaining hygiene and sanitation standards in healthcare facilities, the sluice room has its set of risks. Here are the primary risks associated with the sluice room:

1. Biological Risks

When discussing infections, it’s essential to understand that a sluice room is a hub for processing human waste and soiled medical equipment. If staff do not follow strict hygiene and cleaning procedures, they are vulnerable to infections from pathogens present in feces, urine, or bodily fluids. Such infections could include those caused by bacteria like E. coli or Staphylococcus or viruses like hepatitis B and C, all of which can be present in human waste. The gravity of such risks becomes even more severe when considering bloodborne viruses, which are highly infectious and can have severe health repercussions.

The spread of pathogens in a sluice room isn’t just a direct-contact concern. If the environment isn’t adequately cleaned and disinfected, pathogens can linger and potentially colonize various surfaces. Over time, these pathogens might evolve, becoming resistant to standard disinfectants or antibiotics, making them far more challenging to eradicate. The risk then transcends the sluice room, potentially leading to outbreaks in the broader healthcare setting.

2. Chemical Risks

Chemicals are routinely used in sluice rooms for cleaning and disinfection purposes. These agents, while effective, can pose hazards to staff. Inhaling fumes or direct contact can lead to respiratory issues, skin burns, or allergic reactions. Moreover, chemicals can be corrosive, causing direct harm upon contact, especially if not handled using protective equipment.

The accidental mixing of certain chemicals is another risk. For instance, combining bleach and ammonia produces toxic chloramine vapor, leading to respiratory distress and other health complications. Such incidents can occur if chemicals are stored improperly or staff aren’t adequately trained.

Spillage is a common occurrence in active settings like sluice rooms. Besides the immediate slipping hazard of a chemical spill, skin contact is also dangerous, leading to chemical burns, irritations, or other adverse reactions.

3. Electrical Risks

Like any other room equipped with machinery, the sluice room has electrical hazards. Damaged equipment or frayed cords can expose users to electric shocks, resulting in burns, injuries, or even fatalities. The inherent damp environment of a sluice room amplifies these risks. Electrical devices that aren’t adequately insulated or grounded can become potential electrocution hazards when water is present.

4. Physical Risks

Physical risks in the sluice room aren’t limited to chemicals or electricity. Simple scenarios like wet floors or cluttered walkways can cause slips and falls, potentially leading to fractures, concussions, or other injuries. Furthermore, specialized equipment, like macerators or flusher disinfectors, can cause injuries if not used or maintained properly.

5. Fire Risks

Some cleaning agents and disinfectants are flammable. When stored or used near heat sources or electrical outlets, they can ignite, leading to fires. Also, faulty wiring or malfunctioning equipment can produce sparks, providing an ignition source in an environment potentially rich in flammable materials.

6. Cross-Contamination

Sluice rooms typically have designated areas for clean and soiled items. However, lapses in protocol or oversight can lead to cross-contamination, whereby pathogens from dirty items transfer to clean items, perpetuating the spread of infections.

7. Ergonomic and Mechanical Risks

A sluice room’s design and equipment impact the workers’ health. Rooms or machinery designed without considering ergonomics can force staff into repetitive, uncomfortable positions or movements, leading to musculoskeletal problems. Moreover, machinery with moving parts can pose a risk if safety guards malfunction or operators don’t use them correctly.

8. Environmental Risks

Proper disposal protocols exist for a reason. If waste, especially hazardous or chemical waste, is disposed of irresponsibly, it can harm the environment, contaminating soil or water sources. This negligence can have lasting environmental impacts and harm local ecosystems or communities.

9. Mental and Psychological Risks

Lastly, one mustn’t underestimate the mental toll of working in a sluice room. Exposure to waste, strong odors, and the high-stress nature of ensuring stringent sanitation can be exhausting. Over time, this can lead to burnout, anxiety, or other psychological issues, underscoring the need for regular breaks, support, and mental health resources for staff.

Essential Elements Of Sluice Room

The sluice room is a crucial component of infection control in healthcare facilities. Ensuring it is equipped with essential elements guarantees optimal hygiene and waste management. Here are the essential elements of a sluice room:

- Soiled Area: A designated space for receiving and sorting contaminated or soiled items, ensuring they are kept separate from cleaned and disinfected items to prevent cross-contamination.

- Flusher Disinfector: This appliance is critical for emptying, washing, and disinfecting receptacles like bedpans, urine bottles, and commode pots. It ensures that these items are sanitized before they’re returned to patient use or storage.

- Macerator: Used to dispose of single-use items like pulp containers or incontinence pads. It grinds and flushes them away safely, preventing blockages in the drainage system.

- Hand Washbasin: Given the nature of work in the sluice room, having a sink specifically for handwashing is vital. This station should have antimicrobial soap, a hands-free tap, and disposable hand towels to reduce contamination risks.

- Clean Storage Area: Once items have been disinfected and cleaned, they should be stored in a clean area away from soiled items. This zone might contain shelves, cupboards, or racks.

- Chemical Storage: A lockable cupboard or storage area for the chemicals and disinfectants used in the sluice room ensures they are kept safely from unauthorized access and reduces the risk of misuse or accidents.

- Personal Protective Equipment (PPE): Given the exposure to potentially hazardous materials, staff should have access to PPE like gloves, aprons, masks, and eyewear. A storage area for these is essential.

- Waste Bins: Different waste streams (e.g., clinical waste, general waste, sharps) should have separate and clearly labeled bins.

- Non-slip Flooring: Given the potential for spills and regular water use, the flooring should be non-slip to reduce the risk of accidents.

- Ventilation: Proper ventilation ensures that harmful fumes, especially chemicals, are adequately dispersed. It also helps in reducing bad odors and maintaining air quality.

- Signage: Clear and visible signs indicating procedures, protocols, and instructions help ensure the sluice room operates efficiently and safely.

- Emergency Eyewash Station: In case of accidental splashes, especially from chemicals, an emergency eyewash station can offer immediate relief.

- Lighting: Good lighting ensures that all tasks can be performed efficiently and safely.

Ensuring that a sluice room has all these essential elements, regular training, and protocol adherence ensures a safe and efficient environment for staff and patients.

Safety Protocols in Sluice Rooms

Due to their function and equipment, Sluice rooms present a unique set of hazards. Ensuring the safety of healthcare workers and preventing the spread of infections necessitates implementing stringent safety measures and protocols.

- Personal Protective Equipment (PPE): Staff should wear appropriate PPE when working within the sluice room. This may include gloves, aprons, masks, and protective eyewear. PPE provides a barrier against pathogens and protects against chemical splashes.

- Hand Hygiene: Regular and thorough handwashing is one of the foremost defenses against the spread of infections. Hands should be washed upon entering and before exiting the sluice room, even if gloves have been worn.

- Regular Training: All staff members who access the sluice room should undergo regular training sessions. These sessions should cover equipment operation, handling and disposal of waste, and emergency procedures.

- Clear Signage: Clearly marked signs should be placed around the sluice room, indicating potential hazards, equipment operating instructions, and emergency protocols.

- Chemical Storage: Disinfectants and other chemicals should be stored in a secure, cool, and well-ventilated area, away from direct sunlight. All containers should be clearly labeled, and Material Safety Data Sheets (MSDS) should be accessible nearby for all chemicals.

- Equipment Maintenance: Regular checks and maintenance of equipment ensure they operate safely and efficiently. Any faults or malfunctions should be reported immediately, and the equipment should be taken out of service until repaired.

- Waste Management: Waste should be categorized and disposed of in the appropriate receptacles. Sharp objects like needles should be placed in puncture-proof containers. Regularly empty waste containers to avoid overfilling, which can lead to spills.

- Ventilation: Proper ventilation reduces the concentration of potential airborne pathogens and chemical vapors, ensuring a safer breathing environment for staff.

- Avoiding Cross-contamination: The sluice room should clearly delineate between dirty and clean zones. Items from the dirty zone should never come into contact with the clean zone to prevent cross-contamination.

- Emergency Protocols: Staff should be trained to manage emergencies, whether they are chemical spills, equipment malfunctions, or fire hazards. This includes knowing the location and operation of emergency shut-off switches, eyewash stations, and fire extinguishers.

- Limiting Access: Only trained personnel should have access to the sluice room. This prevents accidental exposure to hazards by untrained staff or visitors.

- Spill Management: In case of a spill, whether a chemical or biological substance, there should be a clear protocol and readily available spill kits. Immediate action minimizes the spread and impact of the spill.

- Regular Audits: Regular safety audits can identify potential hazards or procedural lapses. This proactive approach ensures that safety protocols are always up-to-date and effective.

By strictly adhering to these safety protocols, healthcare facilities can ensure the well-being of their staff and patients and maintain the integrity of the sluice room’s purpose – to provide a safe and effective environment for the disposal and disinfection of clinical waste.

Factors To Consider When Planning A Sluice Room

Various factors must be considered when planning a sluice room to ensure the facility is safe, efficient, and conducive to its intended purpose. Here are some key factors to take into account:

- Size and Layout: The size of the sluice room should be sufficient to accommodate the equipment, personnel, and workflow comfortably. A well-thought-out layout ensures smooth operations, reducing the risk of accidents and cross-contamination.

- Location: The sluice room should be conveniently located near patient areas to minimize the transport of soiled items through the facility. However, it should be sufficiently isolated to prevent the spread of odors and contaminants.

- Ventilation: Proper ventilation is crucial to manage odors, reduce moisture, and disperse potentially harmful fumes from chemicals.

- Durable Materials: Surfaces, especially countertops and floors, should be made of materials resistant to corrosion, easy to clean, and can withstand frequent exposure to water and chemicals.

- Water Access: Access to hot and cold water is essential. Consideration should be given to water pressure and drainage to ensure the efficient operation of equipment like flusher disinfectors.

- Waste Management: Plan for the separate storage and disposal of different waste types, such as clinical waste, general waste, and sharps.

- Safety Features: This includes non-slip flooring, emergency eye-wash stations, clear signage for procedures and hazards, and easily accessible personal protective equipment.

- Storage: Adequate storage for clean and soiled items, chemicals, and personal protective equipment is essential. The design should promote clear separation between clean and soiled zones.

- Ergonomics: The design should promote comfort and efficiency, reducing staff strain or injury risk. This includes the height of work surfaces, equipment placement, and general room flow.

- Equipment Needs: Identify all the necessary equipment for the room, such as macerators, flusher disinfectors, sinks, and storage units, and ensure enough space for them.

- Accessibility: The sluice room should be easily accessible to staff, but access should be restricted to unauthorized individuals to maintain hygiene and security.

- Training and Protocol Display: There should be space for displaying training materials, standard operating procedures, or guidelines for staff reference.

- Emergency Protocols: Consider how emergencies, such as chemical spills or equipment malfunctions, will be handled. This might involve emergency shut-off valves or spill kits.

- Cost and Budget: Ensure all plans align with the budget without compromising essential safety and functionality features.

- Maintenance and Cleaning: The design should facilitate easy maintenance and cleaning. Consider how often maintenance checks will be carried out and ensure that equipment can be easily accessed for repairs or replacements.

- Future Needs and Scalability: The design should be flexible to accommodate future upgrades or increased demand, especially in growing healthcare facilities.

Incorporating these factors into the planning phase of a sluice room ensures its functionality, safety, and longevity, contributing to the overall efficiency and hygiene standards of a healthcare facility.

Maintenance and Operation of Sluice Rooms

Given its critical role in infection control and patient care, the sluice room demands meticulous maintenance and operation. The implications of neglecting this aspect can have direct consequences on patient safety, staff well-being, and the reputation of the healthcare facility.

- Infection Control: At the heart of the sluice room’s purpose is the prevention of infections. Regular maintenance ensures that all equipment operates optimally, from macerators to flusher disinfectors. Any malfunction can result in incomplete disinfection, creating a reservoir for pathogens, which can then be transmitted to patients or staff.

- Safety Concerns: Equipment in the sluice room often deals with high temperatures, sharp blades, and chemicals. A lapse in regular checks or maintenance can expose users to risks such as burns, cuts, or chemical exposures. Additionally, a well-maintained floor minimizes slip hazards, especially in an environment where spillages might occur.

- Efficiency and Workflow: Healthcare professionals often work under time constraints. Equipment that is properly maintained ensures faster and smoother operations. This reduces waiting times and minimizes errors when staff members are rushed.

- Equipment Longevity: Like any machinery, the longevity of sluice room equipment is directly tied to how well it’s maintained. Regular maintenance checks, timely repairs, and replacements can extend the operational life of the equipment, providing a better return on investment.

- Cost Savings: While regular maintenance comes with a cost, it is far more economical in the long run. Preventive maintenance can identify and rectify issues before they escalate into major repairs or complete replacements. Healthcare facilities can avoid the higher costs associated with emergency repairs and potential litigation from health complications due to infection spread by avoiding system breakdowns.

- Operational Standards: Proper operation procedures ensure that all safety and hygiene protocols are met consistently. Training staff to operate equipment correctly not only maximizes the efficiency of the machines but also safeguards the health and safety of both the operators and the patients.

- Environmental Impact: Proper operation and maintenance can minimize waste. For example, a malfunctioning macerator might not process materials effectively, leading to larger waste particles that can block plumbing or create issues in waste management systems.

- Reputation Management: A healthcare facility’s reputation is invaluable. Instances of infection outbreaks, often covered in media, can tarnish the trust patients place in an institution. Regular maintenance and correct operation of sluice rooms can prevent such incidents, ensuring the facility’s credibility remains intact.

- Regulatory Compliance: Many regions have stringent regulations and standards governing healthcare operations, particularly regarding waste management and infection control. Regular maintenance and adherence to operational protocols ensure that healthcare facilities remain compliant, avoiding penalties or potential shutdowns.

In conclusion, the regular maintenance and proper operation of sluice rooms are non-negotiable aspects of healthcare management. By upholding these standards, healthcare facilities can ensure optimal patient care, maintain staff safety, and operate efficiently and cost-effectively.

Environmental Impact of Sluice Rooms

Like other aspects of healthcare operations, the environmental footprint of sluice rooms is significant. While these rooms play a crucial role in maintaining sanitary conditions within healthcare settings, they also have the potential to exert pressure on our environment. Addressing these impacts aligns with broader goals of sustainable healthcare and can result in operational cost savings.

1. Water Conservation

- Usage: Sluice rooms, by design, utilize water for the cleansing and disinfection of medical instruments and human waste. This can lead to high water consumption, especially in larger facilities without efficient fixtures.

- Mitigation: Installing water-efficient appliances, such as high-efficiency flusher disinfectors and tap sensors, can drastically reduce water consumption. Regular maintenance ensures equipment operates efficiently, preventing wasteful leaks or overflows.

2. Pollution Prevention

- Chemical Discharge: When washed away, the disinfectants and other cleaning agents used in sluice rooms can contribute to water pollution. These chemicals may harm aquatic ecosystems and contaminate drinking water sources.

- Mitigation: Using eco-friendly, biodegradable cleaning agents can reduce the environmental toll. Also, proper storage and disposal of chemicals and using the minimum effective amount can minimize their environmental impact. Integrating wastewater treatment systems can also help neutralize harmful agents before they reach external water systems.

3. Waste Management

- Waste Generation: Sluice rooms handle a significant amount of waste, some of which might be non-biodegradable, like certain disposable items. Improper disposal can lead to environmental degradation and pose threats to wildlife.

- Mitigation: Implementing waste segregation practices ensures that biodegradable, recyclable, and hazardous waste are separated and treated appropriately. Opting for sustainable or biodegradable alternatives to single-use items can also reduce environmental harm.

4. Energy Consumption

- Usage: Equipment in sluice rooms, especially those used for heating, disinfection, and maceration, often consumes substantial energy.

- Mitigation: Employing energy-efficient machines, integrating energy-saving practices like turning off machines when not in use, and regular maintenance can result in significant energy savings. Moreover, using renewable energy sources to power sluice rooms can offset their carbon footprint.

5. Habitat Preservation

- Infrastructure Expansion: As healthcare facilities expand, they can encroach upon natural habitats, potentially endangering local flora and fauna.

- Mitigation: When planning new facilities or expansions, considering eco-friendly designs or selecting sites with minimal ecological significance can prevent habitat destruction. Restoring natural habitats after construction or setting aside conservation areas can also help.

While sluice rooms are indispensable to healthcare operations, it’s crucial to recognize their environmental implications. By adopting sustainable practices, healthcare providers can ensure that they protect human health inside their facilities and safeguard the broader environment outside their walls.

Conclusion

In wrapping up our exploration of sluice rooms, it’s evident that their significance stretches far beyond the room’s walls. While they may not be the most celebrated sections of a healthcare facility, their role is undeniably paramount in maintaining hygiene, ensuring patient safety, and upholding the institution’s reputation.

The intricate balance of planning, operation, safety, and environmental considerations emphasizes the complexity and depth of thought that goes into every aspect of healthcare. As we’ve journeyed through the various facets of sluice rooms, one truth stands clear: in the vast orchestra of healthcare, while some rooms may play the leading melodies, it’s spaces like the sluice room that provide the essential harmonies, creating a symphony of cleanliness and care.