I was conducting a site walk on a heavy infrastructure project when I heard the backup alarm of a 30-ton excavator and simultaneous shouting. A subcontractor, engrossed in his phone, had walked straight past a bright red “No Pedestrian Access – Heavy Plant Operations” sign, nearly stepping into the blind spot of the reversing machine. The sign was properly sized, correctly placed, and clearly visible, but it had become background noise to a worker who had seen it every day for six months. I immediately stopped all work in the sector, brought the teams together, and used the near-miss to reinforce a harsh reality: safety signage does not physically stop heavy machinery or falling objects; it relies entirely on human compliance.

In the high-risk environment of construction, ignoring safety signs is not a minor infraction—it is a leading indicator of a deteriorating safety culture that precedes fatalities. From deep excavations and suspended loads to invisible hazards like high voltage and airborne silica, worksites are dynamic death traps if not properly communicated. This article outlines the 25 top construction safety signs you must never ignore, breaking down their real-world significance, the regulatory weight they carry, and how field-level failures in signage lead to life-altering incidents.

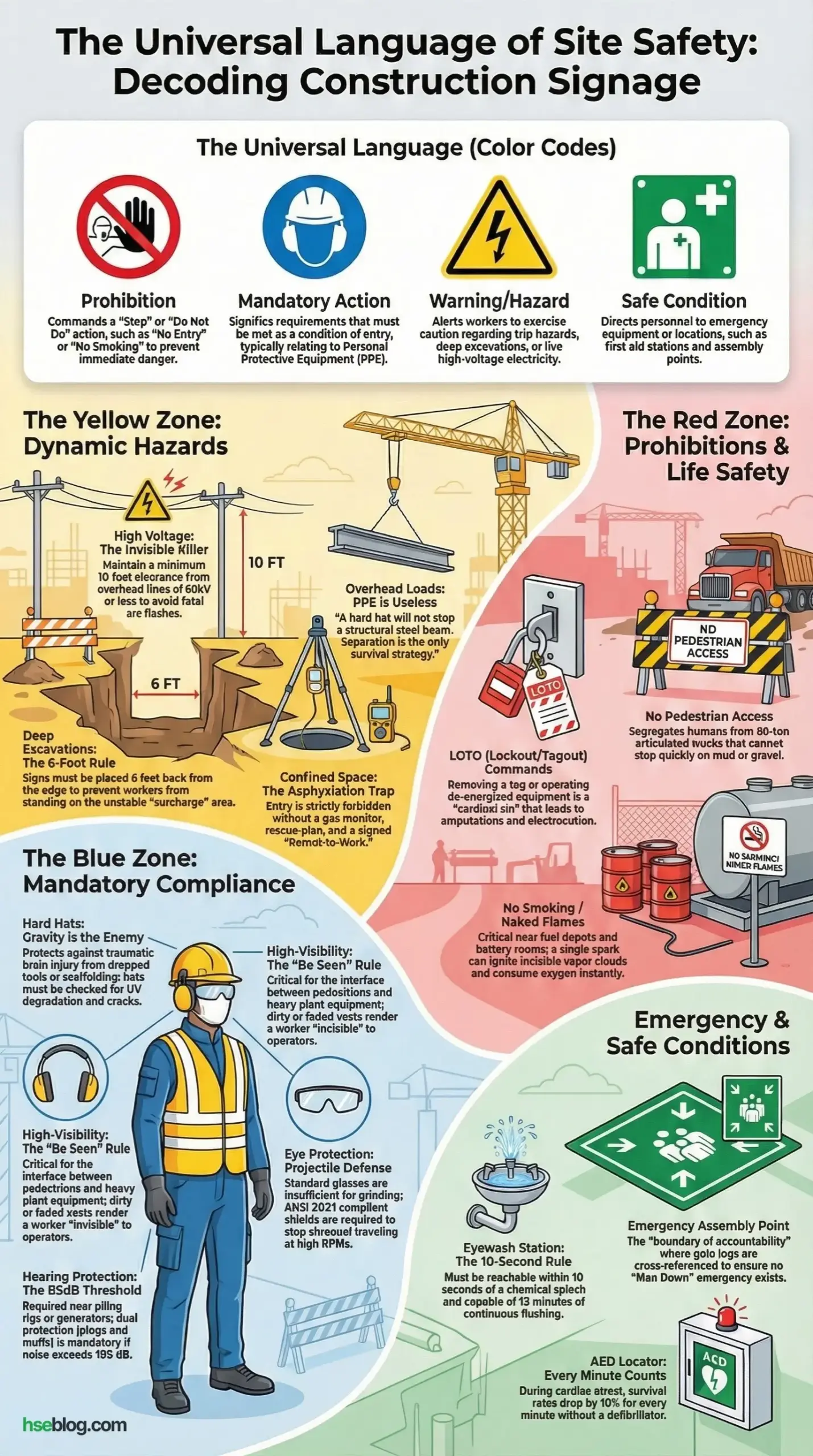

The Universal Language of Danger: Why Color Codes Matter

On a multinational mega-project, you might have workers speaking a dozen different languages. Text fails, but color and pictograms are universal. As a Construction HSE Manager, I rely on the standardized color-coding system to bridge language barriers and trigger immediate psychological responses to danger.

Before understanding the specific signs, it is critical to understand what the colors dictate on a worksite.

| Sign Color | Meaning | Required Action | Common Field Application |

| Red (Circle with slash) | Prohibition | Stop / Do Not Do | No entry, no smoking, lockout tags. |

| Red (Square/Rectangle) | Fire Equipment | Locate / Use | Extinguishers, alarms, fire hoses. |

| Yellow / Amber | Warning / Hazard | Caution / Be Aware | Trip hazards, deep excavations, live voltage. |

| Blue | Mandatory Action | You Must Wear/Do This | PPE requirements (hard hats, boots). |

| Green | Safe Condition | Go to / Use in Emergency | First aid, assembly points, eye wash. |

The 25 Top Construction Safety Signs You Can’t Ignore

To effectively manage a site, I categorize these 25 essential signs by the specific behavioral response they require from the workforce.

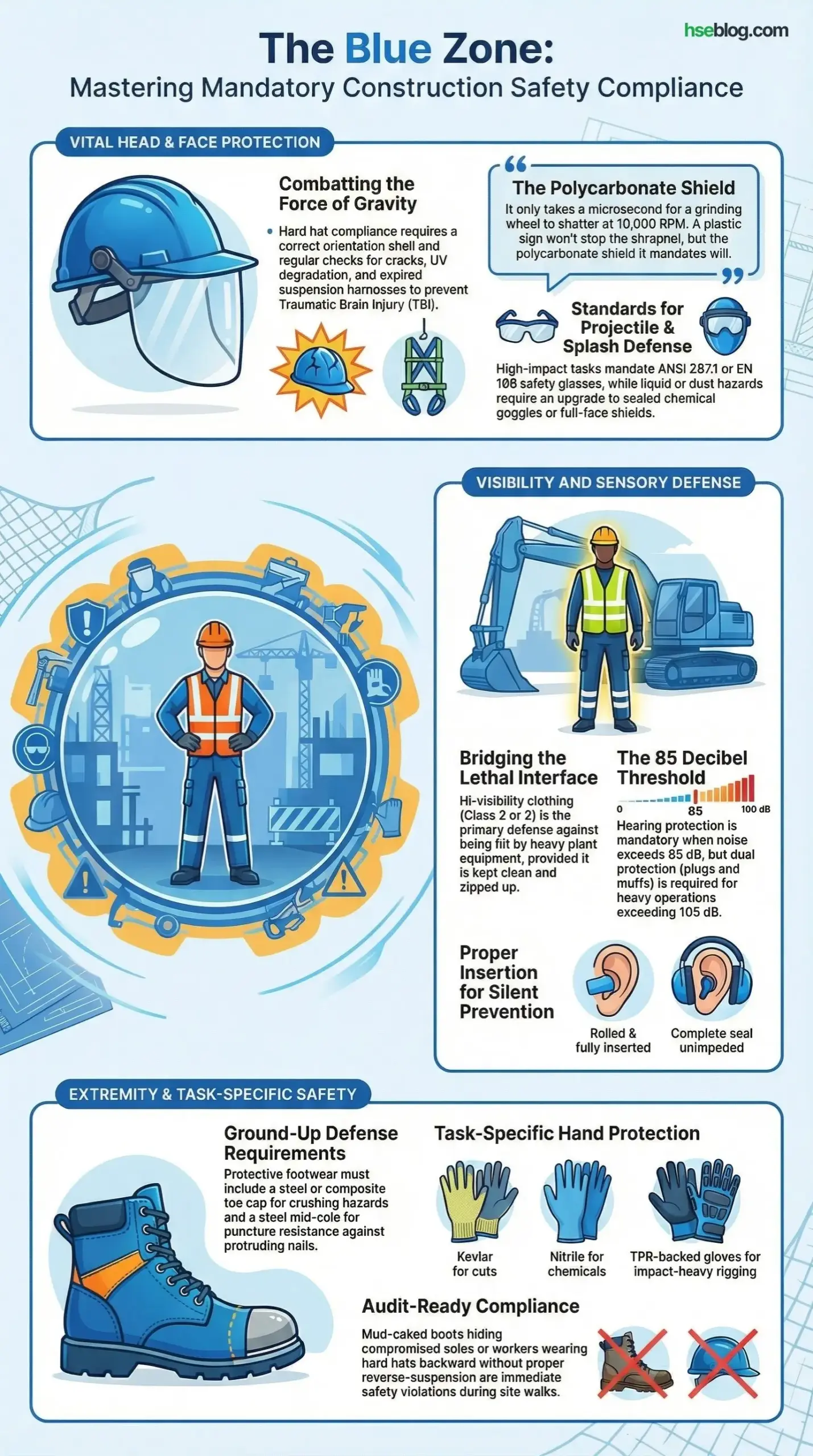

Mandatory Action Signs (The Blue Zone)

These signs do not ask for compliance; they demand it as a condition of entry. Ignoring these during an audit guarantees an immediate non-conformance.

1. Hard Hats Required (Overhead Hazard Control)

A hard hat sign indicates a site where gravity is your enemy. From dropped spanners at height to low-hanging scaffolding tubes, the risk of traumatic brain injury (TBI) is constant.

We don’t just enforce wearing the shell; we enforce wearing it correctly. On my sites, a worker wearing a hard hat backward without the proper reverse-orientation suspension is violating this sign. The sign demands proper impact protection, which includes regular checks for cracks, UV degradation, and expired suspension harnesses.

2. High-Visibility Clothing Required (The “Be Seen” Rule)

This sign bridges the most lethal interface in heavy industry: pedestrians and mobile plant equipment. A 30-ton excavator operator has massive blind spots; hi-vis clothing ensures the worker stands out against a chaotic background.

In the field, dirty or faded hi-vis vests effectively render the worker invisible again. Compliance with this sign means wearing Class 2 or Class 3 reflective gear that is clean, zipped up, and appropriate for day or night operations.

3. Eye Protection Required (Projectile & Splash Defense)

Placed at the entrance to grinding bays, concrete pouring zones, and chemical handling areas, this sign protects the most vulnerable organ on the worksite.

Standard spectacles are rarely enough. For high-impact tasks, this sign mandates ANSI Z87.1 or EN 166 compliant safety glasses. Where liquid splashes or severe dust is present, this upgrades to sealed chemical goggles or full-face shields.

“It only takes a microsecond for a grinding wheel to shatter at 10,000 RPM. A plastic sign won’t stop the shrapnel, but the polycarbonate shield it mandates will.”

4. Hearing Protection Required (Silent Injury Prevention)

Unlike a cut or burn, hearing loss is painless, invisible, and permanent. This sign is posted at the boundaries of any area where ambient noise exceeds 85 decibels (dB), such as near piling rigs or generator farms.

- Earplugs must be properly rolled and inserted into the ear canal, not just resting on the outside.

- Earmuffs must form a proper seal around the ear, unimpeded by thick safety glass frames.

- Dual protection (plugs and muffs) is often required when heavy equipment operations push noise levels above 105 dB.

5. Protective Footwear Required (Ground-Up Defense)

Construction floors are minefields of dropped loads, crushing hazards, and protruding nails. This sign mandates boots that protect the entire foot, not just the toes.

Compliance requires boots with a steel or composite toe cap (for crush resistance) and a steel mid-sole (for puncture resistance). Mud-caked boots that hide compromised soles or exposed steel caps are an immediate safety violation during my site walks.

6. Hand Protection Required (Task-Specific Shields)

Hands are the most frequently injured body part on a construction site. This sign is rarely a blanket requirement; it mandates task-specific gloves to prevent lacerations, chemical burns, or vibration damage.

- Cut-Resistant: Kevlar or HPPE materials for handling sheet metal and glass.

- Chemical-Resistant: Nitrile or Neoprene for handling solvents and wet concrete.

- Impact-Resistant: TPR-backed gloves for heavy rigging and drilling operations.

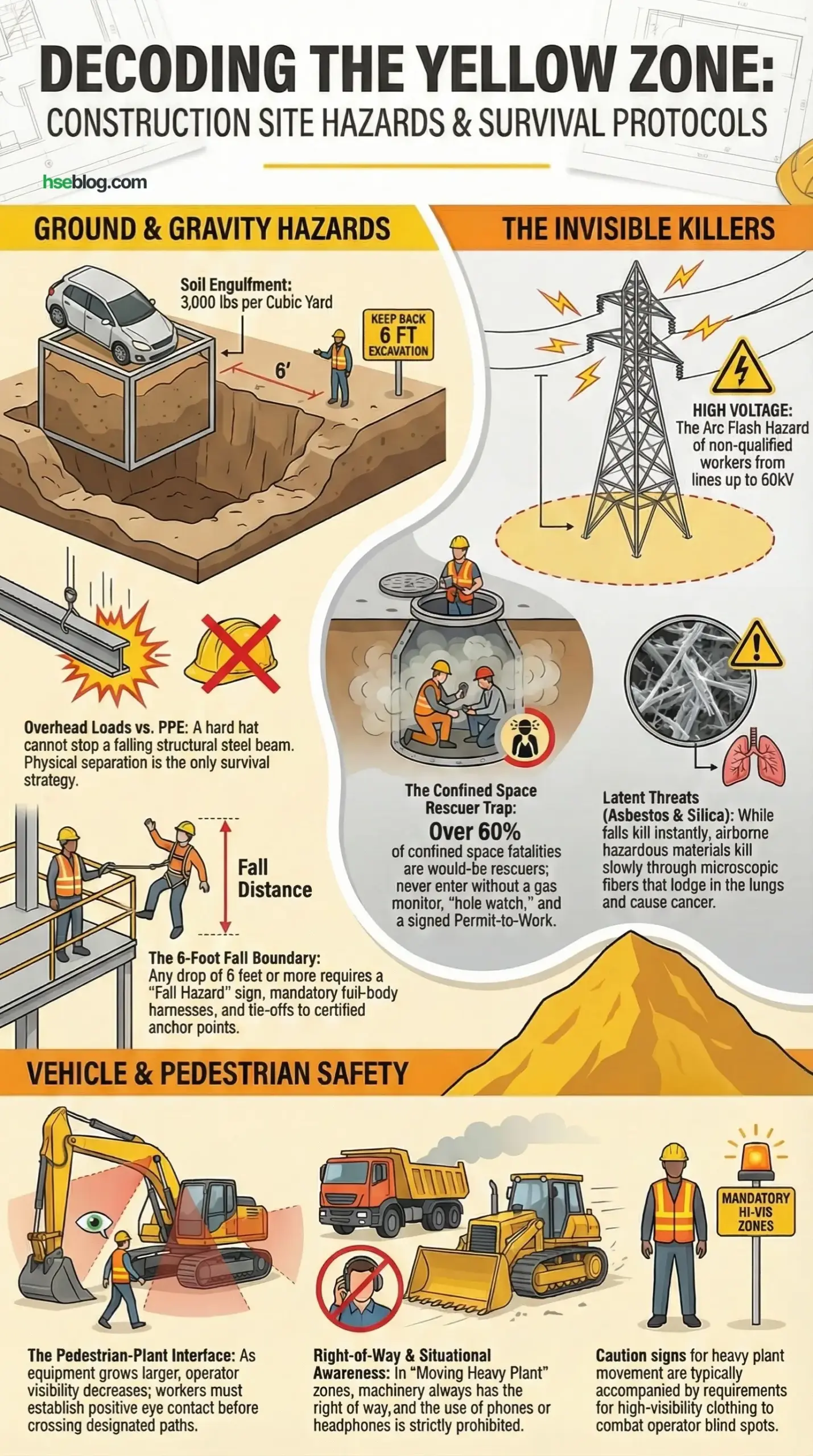

Hazard and Warning Signs (The Yellow Zone)

These signs highlight active, often dynamic hazards. When I investigate incidents, the failure to heed these warnings is frequently the root cause of fatalities.

7. Danger: Deep Excavations (The Engulfment Hazard)

A cubic yard of soil weighs roughly 3,000 pounds—the size of a compact car. This sign warns not just of falling into a hole, but of the surrounding ground collapsing in on you.

When I see this sign on a site, I immediately look for the physical barrier. A sign without a hard barrier (like jersey barricades or clamped scaffold tubes) is a failure of the hierarchy of controls. The most common site-level mistake is placing this sign too close to the edge, encouraging workers to stand on the unstable surcharge area to read it.

- Must be placed at least 6 feet (1.8m) back from the excavation edge.

- Indicates that standard trenching rules apply: sloping, shoring, or shielding are required.

- Warns equipment operators to keep heavy loads away from the fragile trench lip.

8. Danger: Overhead Loads (The Drop Zone)

Gravity never takes a day off, and rigging equipment can fail without warning. This sign establishes the exclusion zone where a suspended load could potentially fall or swing.

I enforce a strict “no human interface” policy under a live load. This sign does not just apply to the area directly beneath the load, but to the entire swing radius of the crane. If a worker crosses this threshold during a lift, the operator must stop the job immediately.

“In heavy lifting operations, ‘Danger: Overhead Loads’ means you are entering an area where your PPE is useless. A hard hat will not stop a structural steel beam. Separation is the only survival strategy.”

9. Danger: High Voltage (The Invisible Killer)

Unlike a spinning blade or an open trench, high-voltage electricity gives no visual or auditory warning until the arc flash occurs. This sign alerts workers to a hazard that can vaporize metal and cause fatal internal burns.

This sign is critical around temporary distribution boards, underground cable strikes, and overhead powerlines. It dictates strict approach limits. Non-qualified workers must maintain a minimum 10-foot clearance from overhead lines of 50kV or less. Ignoring this sign often leads to machinery, like pump trucks or excavators, bridging the gap to ground, electrocuting anyone touching the chassis.

10. Caution: Moving Heavy Plant (The Pedestrian Interface)

Construction equipment is getting larger, and operator visibility is getting worse. This sign warns pedestrians that they are entering the domain of blind spots and reversing hazards.

The biggest mistake I see in audits is placing this sign indiscriminately around the site. It should only be placed at designated pedestrian-plant crossing points. It reminds workers to establish positive eye contact with operators before crossing.

- Demands heightened situational awareness; phones and headphones must be put away.

- Signals that plant equipment always has the right of way.

- Typically accompanied by mandatory Hi-Vis clothing requirements.

11. Danger: Confined Space (The Asphyxiation Trap)

A confined space is not meant for human occupancy and contains hazardous atmospheres. This is perhaps the most critical sign in the industry; entering without authorization is statistically a death sentence.

In the field, over 60% of confined space fatalities are the would-be rescuers who rush in to save a collapsed colleague. This sign means absolutely no entry without a gas monitor, an emergency rescue plan, a hole watch, and a signed Permit-to-Work.

Pro Tip: Under OSHA 1910.146, failing to label a Permit-Required Confined Space is an immediate, willful citation. The sign must explicitly state: “DANGER — PERMIT-REQUIRED CONFINED SPACE, DO NOT ENTER.”

12. Danger: Asbestos / Hazardous Materials (The Latent Threat)

While a fall kills instantly, hazards like silica, asbestos, and lead kill slowly. This sign warns of microscopic airborne hazards that lodge in the lungs.

When placed during renovation or demolition, this sign stops the job. It informs workers that specialized abatement contractors in hazmat suits and HEPA filtration are required. A worker ignorantly sweeping up dust past this sign is inhaling cancer.

13. Caution: Fall Hazard / Open Edge (The Gravity Boundary)

Used around lift shafts, stairwells, and roof perimeters, this sign denotes a drop of 6 feet (1.8m) or more where guardrails may be temporarily removed.

If this sign is present, fall protection is mandatory. This means a full-body harness tied off to a certified anchor point. An open edge sign is a temporary warning during active work (like loading materials); if work is not active, a physical hard barricade must replace the sign immediately.

Field Reality Note: During an OSHA inspection, the absence of a “Confined Space” sign on a tank or manhole is an automatic citation. The regulator views this not just as poor signage, but as a failure to protect human life.

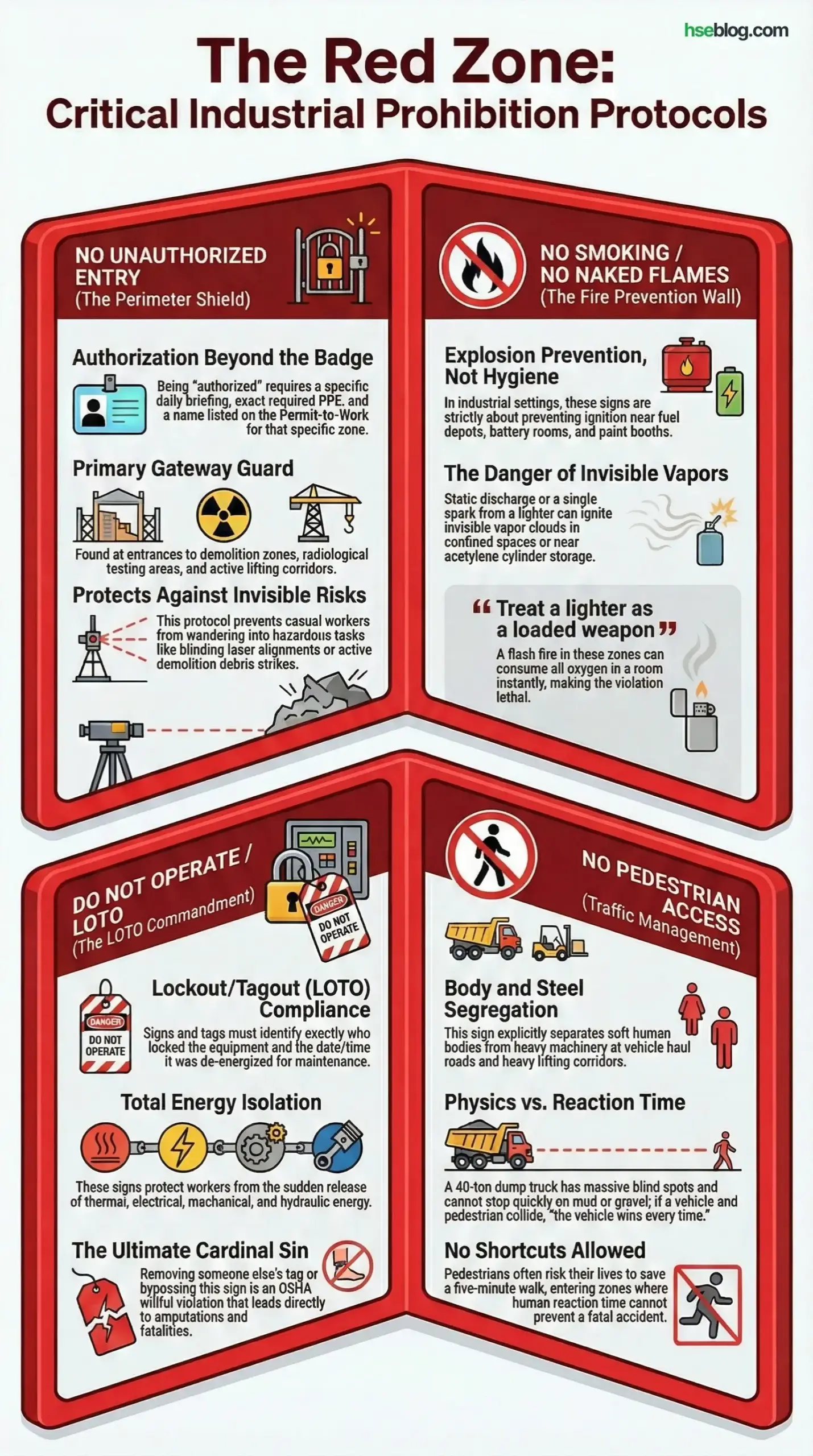

Prohibition Signs (The Red Zone)

These signs draw a hard line in the sand. Breaching a prohibition sign is typically grounds for immediate removal from the site.

14. No Unauthorized Entry (The Perimeter Shield)

This sign serves as the primary gateway guard for high-risk operations. You will see it at the entrances of demolition zones, radiological testing areas, and active lifting corridors.

The critical word here is unauthorized. On my sites, being “authorized” does not just mean you work for the company. It means you have received the specific daily briefing, you are wearing the exact PPE required, and your name is written on the Permit-to-Work for that specific zone.

- Prevents casual workers from wandering into blinding laser alignment tasks.

- Keeps administrative staff out of active demolition zones where debris strikes are highly probable.

- Establishes a legal boundary for trespass during an incident investigation.

15. No Smoking / No Naked Flames (The Fire Prevention Wall)

While commercial “No Smoking” signs are about health and hygiene, on a heavy industrial site, they are strictly about preventing explosions. This sign is non-negotiable near fuel storage depots, battery charging rooms, and paint booths.

Workers often become complacent around vapors they cannot smell. In a confined space or near acetylene cylinder storage, a single spark from a lighter—or even the static discharge from lighting a cigarette—can ignite an Invisible vapor cloud.

“In the field, we treat a lighter in a ‘No Naked Flames’ zone as a loaded weapon. A flash fire doesn’t just burn; it consumes all the oxygen in the room instantly.”

16. Do Not Operate / LOTO (The LOTO Commandment)

Placed on control valves, electrical breakers, and machinery steering wheels, this sign is part of the Lockout/Tagout (LOTO) procedure. It signifies that equipment has been de-energized for maintenance.

Removing someone else’s tag or lock, or operating the equipment while this sign is present, is considered the ultimate cardinal sin in occupational safety. It leads directly to amputations, electrocutions, and crush fatalities.

- The tag must identify who locked the equipment and when.

- Under OSHA 1910.147, bypassing this sign is a willful violation.

- It protects against thermal, electrical, mechanical, and hydraulic energy release.

17. No Pedestrian Access (Traffic Management)

Construction sites are dynamic factories without a roof. This sign explicitly segregates soft, fragile human bodies from hard, heavy steel machinery. It is placed at the entrance to vehicle haul roads and heavy lifting corridors.

A loaded 40-ton articulated dump truck has massive blind spots and cannot stop on a dime, especially on mud or gravel. When pedestrians take “shortcuts” past these signs to save a five-minute walk, they place themselves in a zone where physics dictates the outcome, not human reaction time. If a vehicle and a pedestrian occupy the same space, the vehicle wins every time.

Emergency and Safe Condition Signs (The Green and Fire Zones)

In the chaos of an emergency, workers don’t have time to think—they react. These signs must be the most visible items on the site.

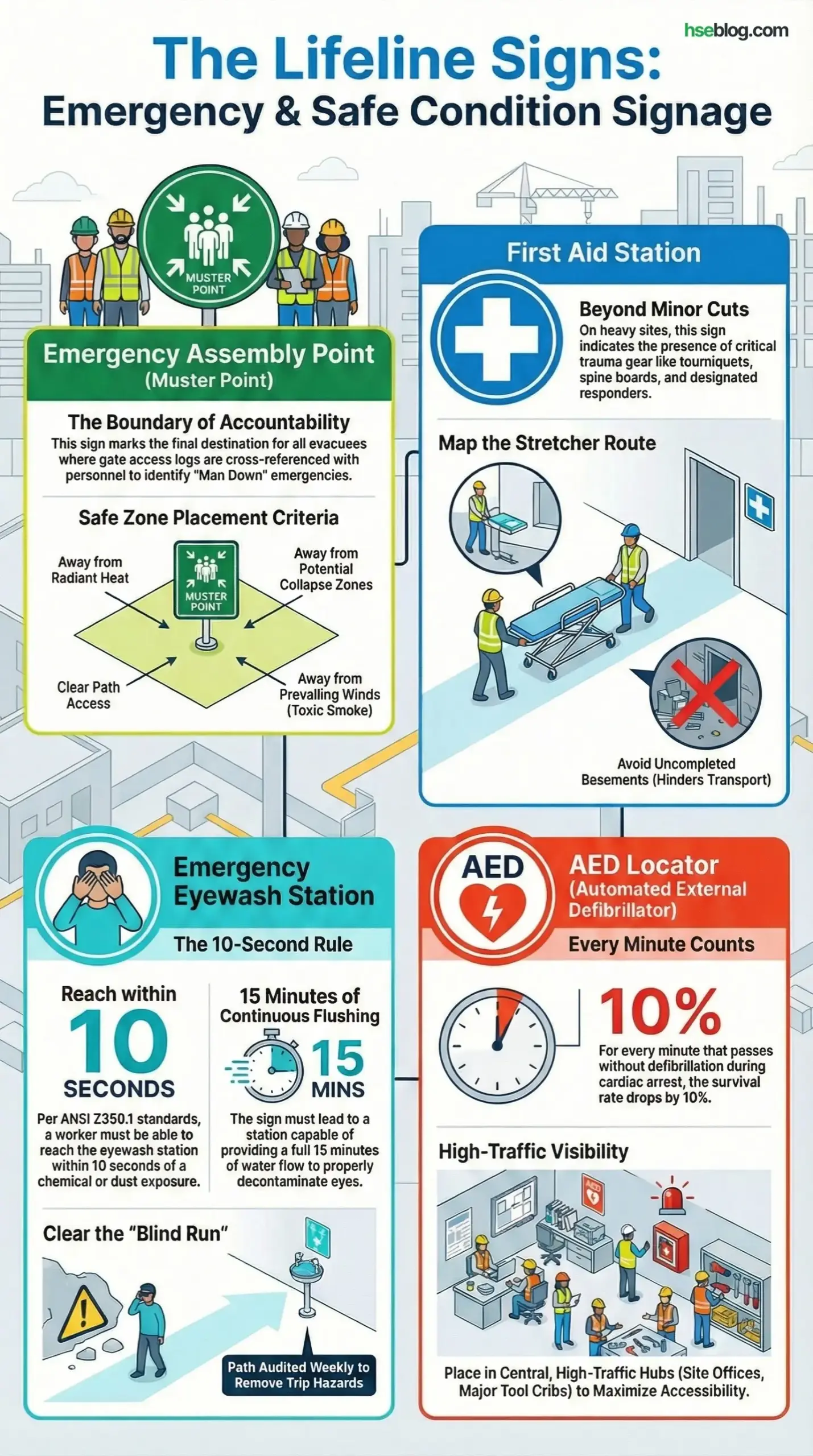

18. Emergency Assembly Point (Muster Point)

This sign marks the ultimate destination during an evacuation. It must be located far away from radiant heat, collapse zones, and prevailing wind directions carrying toxic smoke.

On my sites, the muster point sign represents the boundary of accountability. It is where we cross-reference the gate access logs with the bodies standing in front of us. If a worker doesn’t make it to this sign, we declare a “Man Down” emergency, changing the entire dynamic of the response.

19. First Aid Station

This sign directs injured workers to trauma care. It is not just for minor cuts; on heavy construction sites, this sign indicates the location of tourniquets, spine boards, and designated trauma responders.

Placing this sign correctly means mapping out the route a stretcher would take. It must be in an area accessible by site ambulances, not buried in the basement of an uncompleted high-rise.

20. Emergency Eyewash Station

Crucial near concrete batching plants, battery storage, or chemical processing areas. When a worker has cement dust or acid in their eyes, they are effectively blind. They are relying entirely on their colleagues to spot this sign.

- Regulatory standards (like ANSI Z358.1) require the station to be reached within 10 seconds of the hazard.

- The sign must indicate a station capable of providing 15 minutes of continuous flushing.

- In the field, I audit the path to this sign weekly to ensure no trip hazards block the blind run to the wash basin.

21. AED Locator

Sudden Cardiac Arrest (SCA) is a leading cause of non-impact fatalities on sites, particularly during extreme heat. Every minute without defibrillation drops the survival rate by 10%.

An AED sign signals that the site has invested in life over luck. It tells workers exactly where to find the Automated External Defibrillator. These signs must be placed in central, high-traffic areas like site offices or major tool cribs.

Specialized Site Control Signs

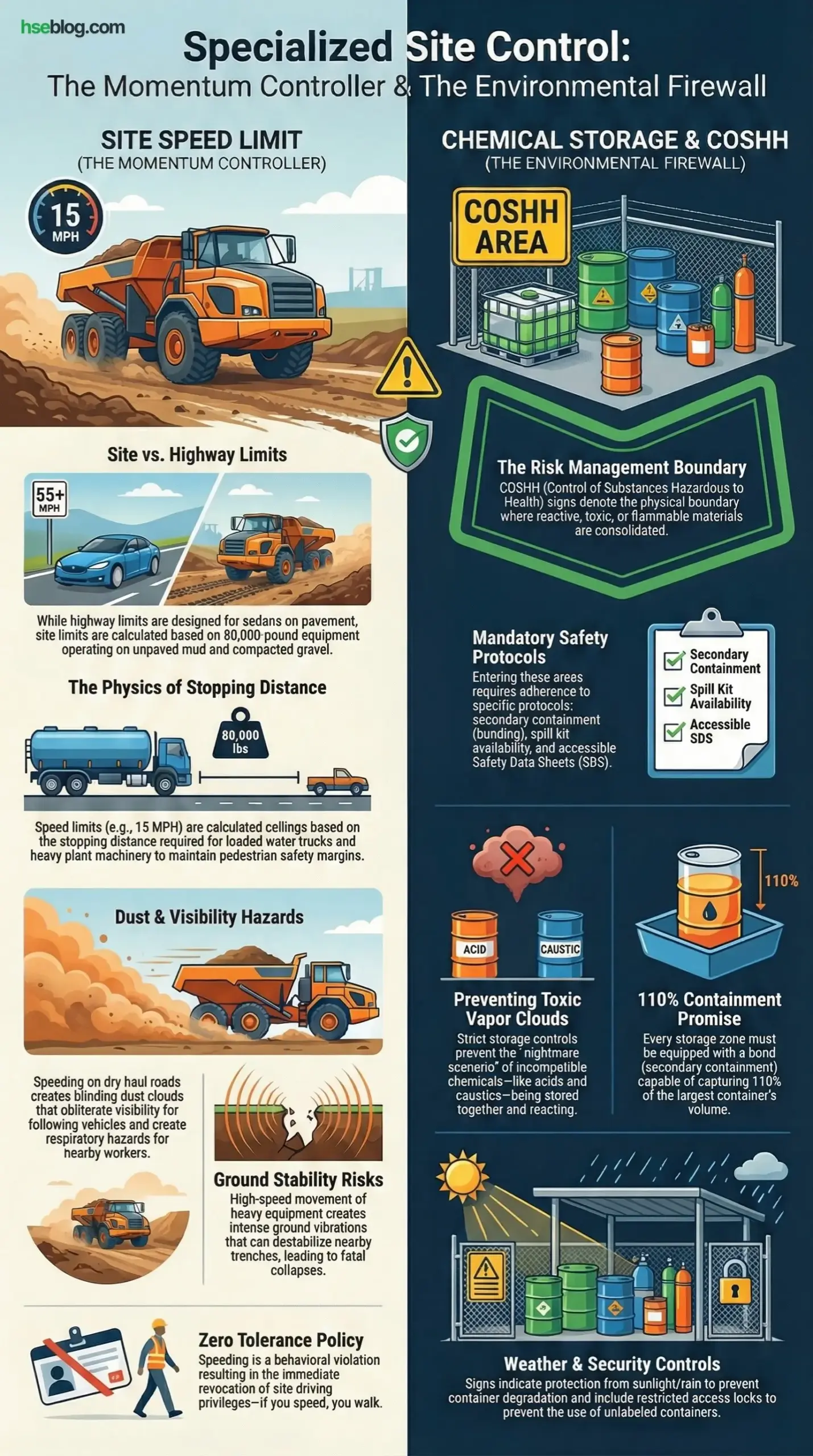

These specialized control signs govern the broader operational ecosystem of a worksite. As an Environmental Compliance and Construction HSE Manager, I know that safety isn’t just about what a worker is doing with their hands—it’s about managing the kinetic energy of moving vehicles and the chemical potential of hazardous substances. Ignoring the “Site Speed Limit” or the “Chemical Storage Area” signs does not just trigger individual injuries; it initiates large-scale operational disasters, environmental catastrophes, and catastrophic regulatory enforcement actions from agencies like the EPA and OSHA.

24. Site Speed Limit (The Momentum Controller)

Public highway limits are based on paved roads and standard sedans. Construction site speed limits are based on unpaved mud, blind corners, and 80,000-pound pieces of mobile equipment.

On my sites, a “15 MPH” sign is a calculated ceiling based on the stopping distance of a loaded water truck on compacted gravel. When drivers violate this limit, they destroy the safety margins designed for pedestrian crossings and intersection sightlines.

- Dust Generation: Speeding on dry haul roads kicks up blinding dust clouds, obliterating the visibility for the vehicles behind them and exposing surrounding workers to respiratory hazards.

- Ground Stability: Heavy plant equipment moving at speed creates intense ground vibrations that can destabilize nearby trenches, leading to fatal collapses.

- Zero Tolerance: Speeding on site is a behavioral violation. My enforcement policy is simple: if you exceed the limit, your site driving privileges are revoked, and you walk.

25. Chemical Storage Area / COSHH (The Environmental Firewall)

COSHH (Control of Substances Hazardous to Health) signs mark the physical boundary of your chemical risk management strategy. They denote areas where reactive, toxic, or flammable materials are consolidated.

This sign signals that specific protocols—secondary containment (bunding), spill kits, and mandatory Safety Data Sheets (SDS)—are in effect. It prevents the nightmare scenario of incompatible chemicals, like acids and caustics, being stored next to each other and creating a toxic vapor cloud.

- Weather Protection: Indicates that materials within are protected from direct sunlight and rain, which can degrade containers and cause catastrophic leaks.

- Spill Containment: The sign is a promise that any leak within that zone will be captured by a bund capable of holding 110% of the largest container’s volume.

- Security: These signs are almost always paired with restricted access locks to prevent unauthorized workers from grabbing unlabeled chemicals in random water bottles.

Pro Tip: During an environmental audit, the first thing I check is whether the inventory inside the COSHH storage area matches the manifest on the door. If a drum of solvent is missing from the list, the entire chemical control process is compromised.

Field Execution: Why Signs Fail on Real Worksites

Having the right signs in a catalog is easy; executing them in the field is where most projects fail. Signage loses its authority when it is not actively managed.

If a “Danger: Deep Excavation” sign is left up three weeks after the trench has been backfilled, workers learn that the signs are lying. We call this “sign blindness.” Furthermore, signs on active construction sites get covered in dust, concrete splatter, and mud. If a sign is illegible, it doesn’t exist.

Pro Tip: Treat signage as a temporary, dynamic control. During the weekly site safety walk, my team maps out where signs need to be added, moved, or removed to match the current phase of construction. If the hazard moves, the sign must move with it.

Conclusion

Effective safety signage in construction is not about decorating fences or pleasing auditors; it is about providing workers with the vital intelligence they need to navigate a landscape of shifting hazards. The 25 signs listed above represent the boundary between a standard workday and a life-altering incident.

As leaders, supervisors, and workers, we must respect the authority of these signs, keep them visible, and maintain their credibility by ensuring they accurately reflect the real-time dangers of the site. A piece of plastic cannot save a life, but the respect for the message printed on it certainly can.