Every day, workers are injured on the job due to machinery hazards. In some cases, these injuries are fatal. Employers need to understand the dangers associated with machinery and take steps to protect their workers. Most machinery has the potential to cause injury to people.

These injuries may range in severity from a minor cut or bruise through various degrees of wounding and disabling mutilation to crushing decapitation or other fatal injuries. It is not solely powered machinery that is hazardous, for many manually operated machines (e.g., hand-operated guillotines and fly presses) can still cause injury if not properly safeguarded.

Machinery accidents figure prominently in official accident statistics, and minimizing the risks posed by machinery in the workplace is important. Proper training, maintenance, and safety procedures can help to reduce the likelihood of an accident occurring, and effective safeguards can help to protect workers from injury if an accident does occur.

By taking these precautions, we can help to make the workplace safer for everyone. In this blog post, we will discuss common machinery hazards and control measures that can be taken to reduce the risk of injury.

What is Mechanical Safety?

Mechanical Safety is the practice of protecting workers from exposure to potential mechanical hazards. In the United States, OSHA‘s Mechanical Safety Standard (29 CFR 1910.219) requires employers to protect workers from exposure to moving machinery and equipment parts.

Mechanical safety is important because it protects workers from injuries when exposed to moving machinery and equipment parts. Injuries that can occur include cuts, bruises, and fractures. Employers can prevent these injuries by protecting workers from exposure to these hazards.

When assessing the risks associated with machinery, it is important to consider all potential hazards, both those that are always present and those that can appear unexpectedly. All phases of the machine life cycle need to be considered, including transport, assembly, and installation; commissioning; use; maintenance; dismantling, disabling, and scrapping. By considering all possible hazards, it is possible to develop a comprehensive risk management plan that will help to keep workers safe and minimize the possibility of accidents.

What Is Considered To Be Machinery?

Machinery generally refers to the machines that are used in industrial applications. These machines are usually powered by electricity and perform various industrial tasks. Some examples of machinery include lathes machines, milling machines, drill presses, and injection molding machines.

Why Is Machinery Safety Important?

Faulty machinery can lead to severe injury and/or death. This is why it’s critically important that all machines be properly maintained, inspected, and used correctly. Machinery safety is important for several reasons, some of which include:

- Moving machinery can cause injuries in many ways:

- People can be struck and injured by moving parts of machinery or ejected material. Parts of the body can also be drawn in or trapped between rollers, belts, and pulley drives.

- Sharp edges can cause cuts and severe injuries, sharp-pointed parts can cause stabbing or puncture of the skin, and rough surface parts can cause friction or abrasion.

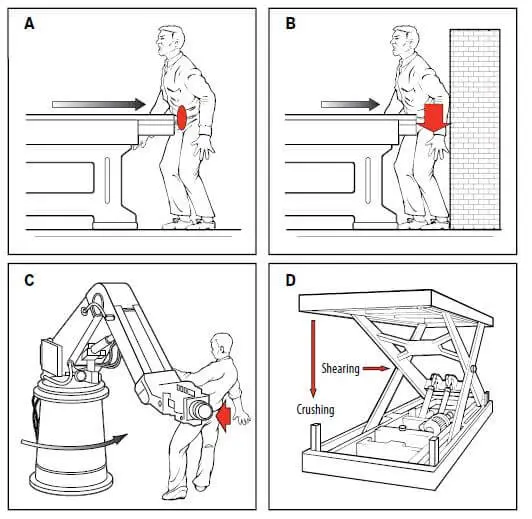

- People can be crushed between parts moving together or towards a fixed part of the machine, wall, or another object, and two parts moving past one another can cause shearing.

- Parts of the machine, materials, and emissions (such as steam or water) can be hot or cold enough to cause burns or scalds, and electricity can cause electrical shock and burns.

- Injuries can also occur due to machinery becoming unreliable and developing faults or when machines are misused through inexperience or lack of training.

Mechanical Machinery Hazards & Control Measures

There are many potential hazards associated with machinery. Some of these hazards are always present, while others can appear unexpectedly. It is important to be aware of all potential hazards in order to develop a comprehensive risk management plan.

The following are some common hazards associated with machinery:

1. Crushing Hazards

On construction sites, crushing hazards are often caused by excavators and other heavy machinery. If an employee is struck by a piece of machinery, it can result in serious injuries or even death. Employees should always be aware of their surroundings and clear areas where heavy machinery operates to prevent crushing hazards. Workers should wear personal protective equipment (PPE) to protect themselves from potential hazards if necessary.

Crushing hazards can also occur when workers are performing maintenance on machinery. If workers are not properly trained to safely perform maintenance, they could be seriously injured or killed. To prevent these hazards, employers need to provide employees with proper training and safety procedures.

2. Shear Hazards

Shear hazards are caused by moving parts that can cut or slice through skin and flesh. Shear hazards can occur when workers use hand-operated tools, such as knives, or when operating machinery with moving parts, such as saws. Employees should always use the proper safety equipment and procedures when working with hand-operated tools or machinery to prevent shear hazards.

3. Cutting/Severing Hazards

There are many types of cutting hazards, but the three most common are contact with a moving sharp-edged part, contact with a rotating part, and contact with a moving part.

- The first type of cutting hazard is contact with a moving sharp-edged part. This can happen when using a machine with a blade, such as a bandsaw. If the blade is not properly guarded, your clothing or skin can come into contact with the blade and be cut.

- The second type of cutting hazard is contact with a rotating part. This can happen when you are using a drill press or lathe. If the chuck or bit is not properly secured, your clothing or skin can come into contact with the rotating part and be cut.

- The third type of cutting hazard is contact with a moving part. This can happen when you are using a power saw or drill. If the blade or bit is not properly secured, your clothing or skin can come into contact with the moving part and be cut.

To avoid these hazards, always ensure that the blades on your machines are properly guarded and that the chucks and bits on your drill presses and lathes are properly secured. If you use a power saw or drill, ensure the blade or bit is not worn or damaged. Also, always wear proper protective clothing, such as gloves, when using machinery.

4. Drawing In Or Trapping Hazards

This hazard can occur when clothing or body parts become caught in moving parts of a machine. The result can be severe injuries or even death. Always wear protective clothing, such as gloves and long sleeves, to prevent this hazard when working with machinery.

Also, keep your hands and feet away from moving parts and ensure that hair is tied back so it cannot become caught in machinery.

5. Stabbing or Puncture Hazards

Stabbing or puncture hazards can occur when using a machine with a pointy or sharp edge, such as a drill press. If the bit is not properly secured, your clothing or skin can come into contact with the pointy or sharp edge and be punctured. Always ensure the bit on your drill press is properly secured to prevent this hazard. Also, wear proper protective clothing, such as gloves, when using machinery.

7. Friction or Abrasion Hazards

Friction and abrasion hazards are often found in mechanical machinery. When contact is made with a fast-moving surface that may be smooth (e.g., touching a spin dryer) or rough (e.g., touching a belt sander), there is a potential for serious injury.

There are several ways to protect yourself from these hazards:

- Wear appropriate Personal Protective Equipment (PPE), such as gloves, safety glasses, and ear protection.

- Be aware of your surroundings and stay clear of moving parts.

- Follow the manufacturer’s instructions for operating the machinery safely.

8. Entanglement Hazards

Entanglement hazards can occur when clothing or body parts become caught in moving parts of a machine. The result can be severe injuries or even death.

There are several ways to prevent this from happening:

- Keep your hair pulled back and away from rotating machine parts.

- Wear close-fitting clothes that won’t get caught on anything.

- Be aware of your surroundings and what you’re doing at all times.

If you see someone else caught in a machine, don’t try to help them yourself. Turn off the machine and get help from someone who can safely release them.

Entanglement is a very real hazard in any industry that uses machinery. By taking some simple precautions, you can prevent it from happening to you or anyone else.

9. Impact Hazards

The most common type of impact hazard is when the body is struck by a powered part of a machine. This is similar to crushing, but there is no fixed structure to trap the person. The speed and weight of the object do the damage.

Impact hazards can also occur when two parts of a machine collide. This can happen when two machine parts are not properly aligned or when one part breaks and hits another. Impact hazards can also occur when a person is hit by a flying object thrown or ejected from a machine.

Impact hazards can be prevented by proper maintenance of machines, training of workers, and use of safety devices. Impact hazards can also be minimized by the use of guards and barriers. When working with machines, it is important to be aware of the potential for impact hazards and to take precautions to avoid them.

10. High-pressure Fluid Injection Hazards

High-pressure fluid injection is a hazard that can occur when fluids are forced into the body at high pressures. This can happen when a person is cleaning a machine with high-pressure water and the nozzle breaks or when a person is hit by a high-pressure fluid from a ruptured hose. The high-pressure fluid injection can also occur when a person is welding, and the arc flashes back, injecting molten metal into the body.

The high-pressure fluid injection can cause serious injuries or even death. Always use proper safety equipment to prevent this hazard when working with high-pressure fluids. Wear goggles or a face shield to protect your eyes, and wear gloves and protective clothing to protect your skin. Wear a welding helmet to protect your face and neck if you are welding.

Non-Mechanical Machinery Hazards & Control Measures

There are many types of hazards associated with non-mechanical machinery. Some of the most common are listed below.

1. Electricity

When working with non-mechanical machinery, it is important to be aware of the potential electrical hazard. This can occur when the machine is not properly grounded or there is a break in the electrical circuit. If you are using machinery that is not properly grounded, you could be at risk for electrocution. To avoid this hazard, follow the manufacturer’s instructions for proper grounding.

If you are working with a machine with a break in the electrical circuit, you could be at risk for an electrical fire. To avoid this hazard, follow the manufacturer’s instructions for proper circuit protection. Awareness of these hazards and taking proper precautions can help keep you safe when working with non-mechanical machinery.

2. Noise

Noise is a non-machinery hazard that can occur when using certain machinery. This can happen when the machine is not properly muffled or there is a break in the sound-proofing material. Noise can also be a hazard when the machine is not properly shielded. Sometimes, noise can even be a hazard when the machine is turned off. If you are working with a machine that produces noise, it is important to take precautions to protect yourself from this hazard.

There are several ways that you can protect yourself from noise. First, you can make sure that the machine is properly muffled. This will help to reduce the amount of noise that is produced. Second, you can make sure that the machine is properly shielded. This will help to reduce the amount of noise that is produced. Finally, you can ensure the machine is turned off when not in use. This will help to reduce the amount of noise that is produced.

3. Vibration

Vibration is a hazard that can occur when using non-mechanical machinery. This can happen when the machine is not properly balanced or there is a vibration-dampening material break. Vibration can also be a hazard when the machine is not properly shielded.

Exposure to vibration can cause a variety of health problems, including:

- Musculoskeletal disorders

- Blood vessel damage

- Nerve damage

- Inner ear damage

- Reduced blood flow to the hands and feet

If you are exposed to vibration on a regular basis, it is important to take steps to protect yourself. Some ways to do this include:

- Wearing vibration-dampening gloves

- Using a vibrating platform during breaks

- Taking regular breaks from exposure to vibration

If you think you may be suffering from a health problem caused by exposure to vibration, it is important to see a doctor as soon as possible. Early diagnosis and treatment can help to reduce the severity of the condition.

4. Hazardous Substances

A hazardous substance is a non-machinery hazard that can occur when using non-mechanical machinery. This can happen when the machine is not properly ventilated or there is a break in the containment system. Hazardous substances can also be hazardous when the machine is not properly labeled. Improper ventilation or a break in the containment system can release hazardous substances into the air, which can be breathed in by people working nearby. Hazardous substances can also come into contact with skin, eyes, or clothing and cause irritation, burns, or other injuries.

If you are working with hazardous substances, taking precautions to protect yourself and others is important. Ensure the area is well-ventilated, wear appropriate personal protective equipment, and follow all safety procedures. If you think you or someone else has been exposed to hazardous substances, seek medical attention immediately.

5. Ionising Radiation

Ionizing radiation is a hazard that can occur when using non-mechanical machinery. This can happen when the machine is not properly shielded or during a break in the containment system. Ionizing radiation can also be hazardous when the machine is not properly labeled.

There are three main types of ionizing radiation: alpha, beta, and gamma. All three can be extremely harmful to human health if not properly controlled.

- Alpha particles are the heaviest and most energetic type of radiation, making them the most dangerous. They can easily penetrate the skin and enter the body, where they can cause damage to DNA and other cells.

- Beta particles are lighter and less energetic than alpha particles, but they can still penetrate the skin and cause damage to DNA.

- Gamma rays are the lightest and least energetic type of ionizing radiation, but they can penetrate deep into the body, causing damage to DNA and other cells.

There are a number of ways to control the hazards posed by ionizing radiation. One is to use lead shielding, which can block alpha and beta particles. Another is to use distance, which can reduce the amount of radiation exposure. Finally, time can be used to reduce the amount of time spent in an area with high levels of ionizing radiation.

6. Non-ionising Radiation

When using non-mechanical machinery, knowing the hazards of non-ionizing radiation is important. This type of radiation can occur when the machine is not properly shielded or there is a break in the containment system. Non-ionizing radiation can also be hazardous when the machine is not properly labeled.

A few simple steps can be taken to help avoid these hazards. First, make sure that the machine is properly shielded. Second, check for breaks in the containment system. Finally, make sure that the machine is properly labeled. Taking these simple precautions can help ensure your safety when using non-mechanical machinery.

7. Extreme Temperatures

One hazard that is often overlooked in non-mechanical machinery is extreme temperatures. Whether it is freezing cold or blistering hot, exposure to extreme temperatures can cause serious injuries or even death. In fact, extreme heat is one of the leading causes of occupational fatalities in the United States. OSHA reports that approximately 40 workers die from heat exposure every year.

There are a number of ways to protect yourself from extreme temperatures when working with non-mechanical machinery. If possible, avoid working in extreme conditions altogether. If you must work in hot or cold conditions, take frequent breaks to cool down or warm up as needed. Wear appropriate clothing for the conditions, and drink plenty of fluids to stay hydrated. If you feel dizzy, lightheaded, or nauseous, stop working and seek medical attention immediately.

Taking precautions and being aware of the dangers can help keep yourself safe while working with non-mechanical machinery.

8. Ergonomics

Ergonomics is a non-machinery hazard that can affect workers who perform tasks that require them to use their bodies in awkward or repetitive ways. Poor ergonomic conditions can lead to injuries of the muscles, tendons, and nerves, as well as back pain and other musculoskeletal disorders. To prevent these injuries, ergonomic principles should be followed when performing tasks.

There are many ways to apply ergonomic principles to task performance. First, workers should be aware of their own body mechanics and how they can use them to their advantage. Second, workers should be aware of the hazards associated with their tasks and take steps to avoid them. Finally, workers should use proper lifting techniques and posture when performing tasks requiring lifting or moving heavy objects. Workers can help prevent musculoskeletal injuries and other health problems by following these ergonomic principles.

9. Machine Maintenance

Another hazard that is often overlooked in non-mechanical machinery is poor maintenance. When machines are not properly maintained, they can become unsafe to use. This can lead to a number of hazards, including electrical shocks, fires, and explosions. In order to prevent these hazards, it is important to perform regular maintenance on all machines.

A few simple steps can be taken to ensure proper machine maintenance. First, read the owner’s manual and follow all instructions. Second, perform regular visual inspections of all machines. Finally, keep all machines clean and free of dust and debris. By taking these simple steps, you can help ensure your safety when using non-mechanical machinery.

10. Slips, Trips, and Falls

Another hazard often overlooked in non-mechanical machinery is the potential for slips, trips, and falls. These hazards can occur when workers are not paying attention to their surroundings or when they are not using proper safety equipment. Slips, trips, and falls can lead to several injuries, including cuts, bruises, broken bones, and head injuries. To prevent these hazards, it is important to be aware of your surroundings and to use proper safety equipment when working with non-mechanical machinery.

Simple steps can be taken to prevent slips, trips, and falls. First, always wear proper footwear when working with non-mechanical machinery. Second, be aware of your surroundings and look for potential hazards. Finally, use proper safety equipment when working with non-mechanical machinery. By taking these simple steps, you can help prevent slips, trips, and falls.

11. Fire and Explosion

Another hazard often overlooked in non-mechanical machinery is the potential for fire and explosion. This hazard can occur when flammable materials are present near heat sources or when electrical equipment is not properly maintained. Fire and explosion can lead to several injuries, including burns, smoke inhalation, and death. To prevent this hazard, it is important to be aware of fire hazards and to take steps to prevent them.

A few simple steps can be taken to prevent fire and explosion. First, always keep flammable materials away from heat sources. Second, perform regular maintenance on all electrical equipment. Finally, have a fire extinguisher readily available in case of an emergency. By taking these simple steps, you can help prevent fire and explosion.

12. Chemical Hazards

Another hazard often overlooked in non-mechanical machinery is the potential for chemical hazards. This hazard can occur when chemicals are not properly stored or used. Chemical hazards can lead to several injuries, including chemical burns, respiratory problems, and death. To prevent this hazard, it is important to be aware of the dangers of chemicals and to take steps to avoid them.

A few simple steps can be taken to prevent chemical hazards. First, always store chemicals in proper containers and in a safe location. Second, be aware of the dangers of chemicals and follow all safety instructions. Finally, wear proper protective clothing when working with chemicals. By taking these simple steps, you can help prevent chemical hazards.

Conclusion

Mechanical or Non-mechanical machinery can be hazardous if not used or maintained properly. To prevent these hazards, it is important to be aware of the dangers and to take steps to avoid them. This article’s simple tips can help ensure your safety when working with non-mechanical machinery.

We hope you found this article helpful. If you have any questions or comments, please leave them in the comment section below. Thanks for reading!