I’ve walked into too many site kitchens and workshops where the fire blanket was tucked away in a drawer or, worse, still in its original plastic wrap inside a locked cabinet. A fire blanket is a highly flame-retardant sheet, typically made of woven fiberglass or occasionally Kevlar, designed to withstand temperatures up to 500°C or more.

In the field, we view these as the first line of defense for small, contained fires. Unlike an extinguisher, they don’t leave a mess of dry powder or foam, which is critical in clean environments like laboratories or food prep areas. They are simple, passive safety devices that require no moving parts, making them incredibly reliable if maintained correctly.

TL;DR

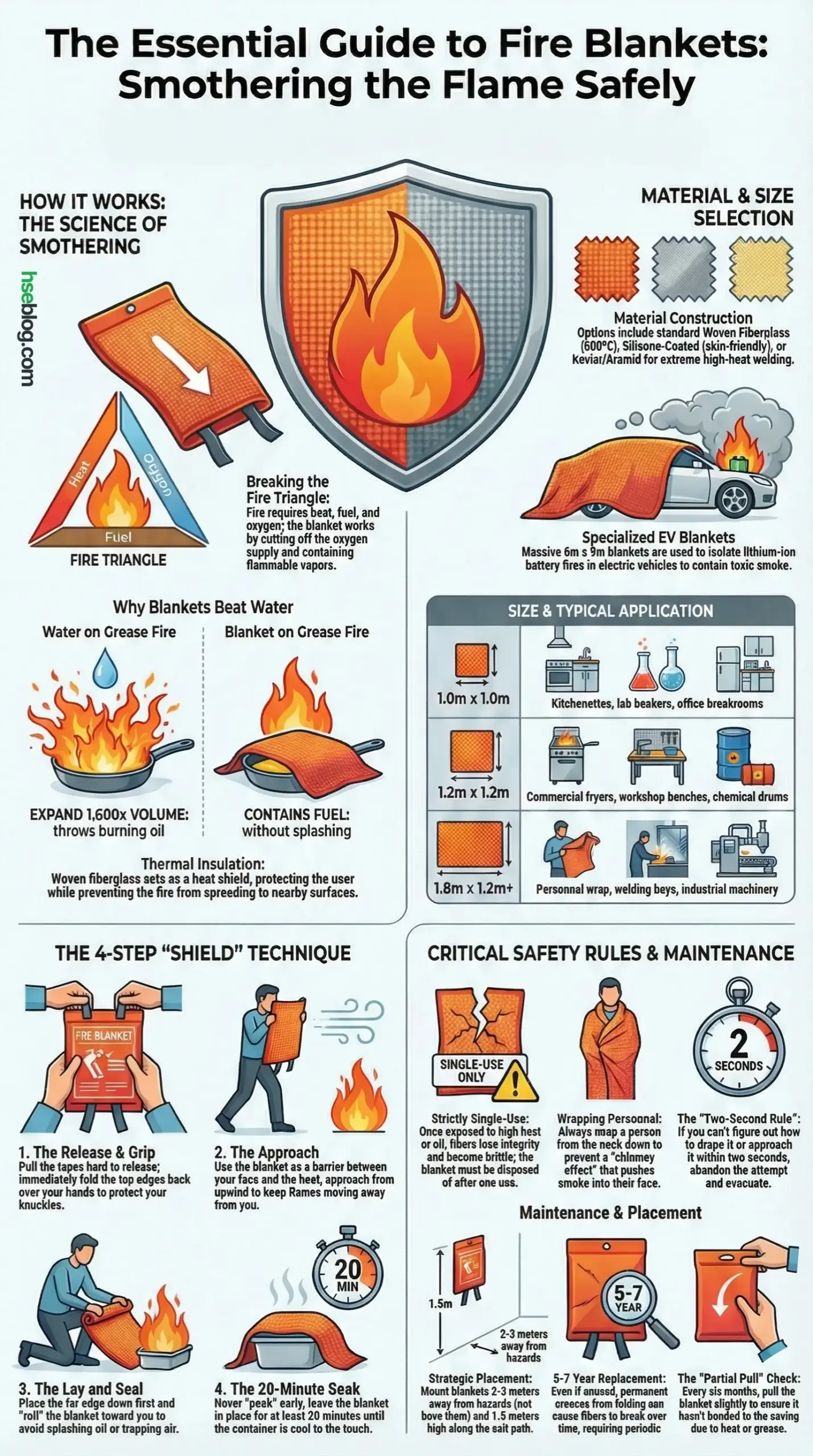

- Primary Function: Fire blankets work by smothering, cutting off the oxygen supply required for combustion.

- Best Use Cases: Ideal for Class F (K) cooking oil fires and wrapping around people whose clothing has caught fire.

- One-Time Use: Never reuse a fire blanket; once used, the fibers are compromised and the blanket must be disposed of.

- Storage: Must be mounted in an accessible location—usually between the hazard and the exit—but never directly above a potential fire source.

How Do Fire Blankets Work?

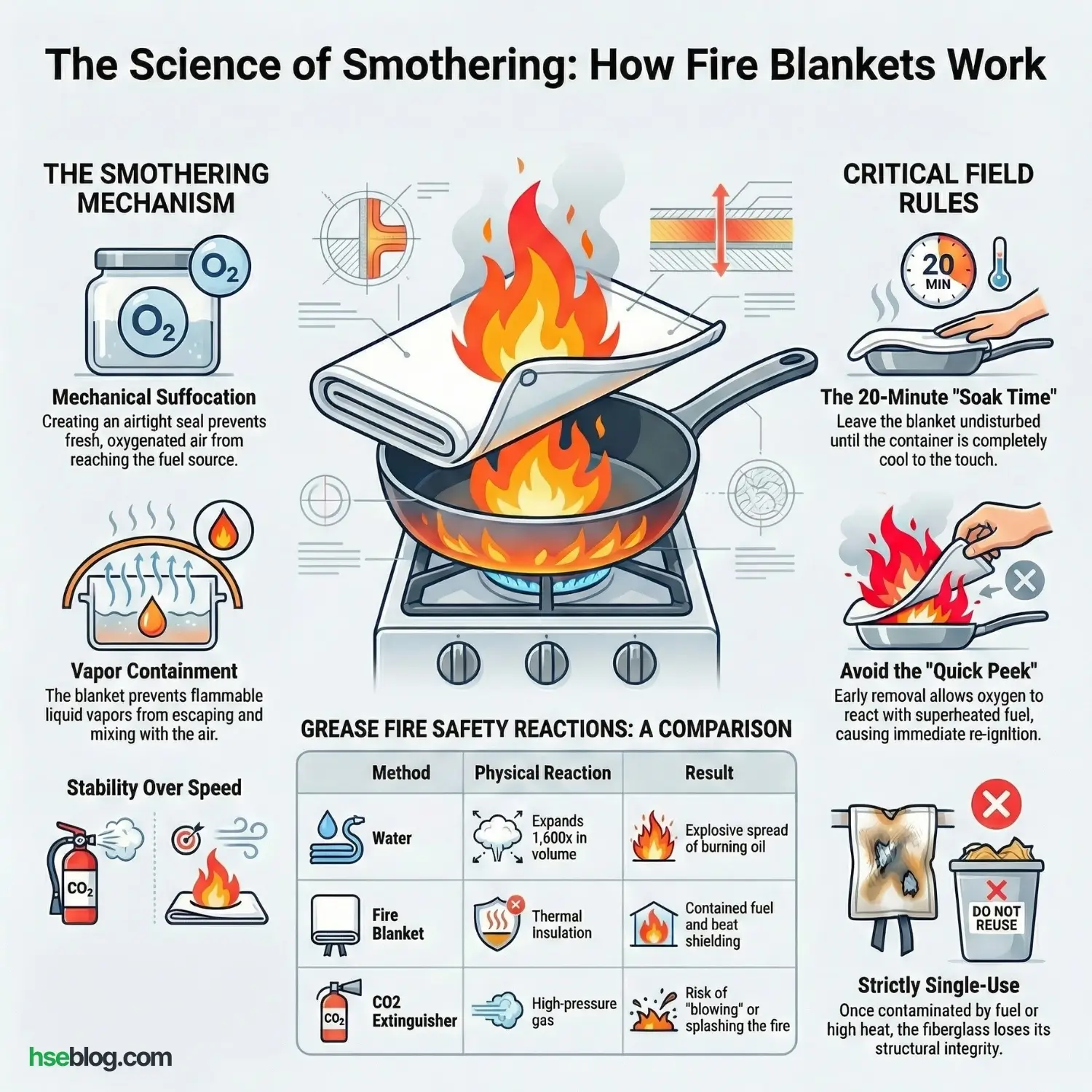

To understand why a fire blanket is effective, you have to look at the chemistry of combustion. In the field, we refer to the Fire Triangle: a fire cannot exist without the simultaneous presence of heat, fuel, and oxygen. If you remove just one of these elements, the fire is suppressed.

While an extinguisher might use chemicals to interfere with the flame or water to reduce heat, a fire blanket works through mechanical suffocation.

The Mechanism of Smothering

The primary function of a fire blanket is to create an airtight seal over a burning object. This process, known as smothering, works through the following stages:

- Oxygen Depletion: Once the blanket is draped over the fire, it prevents fresh, oxygenated air from reaching the fuel source.

- Containment of Vapors: For fires involving liquids (like cooking oil), the blanket prevents flammable vapors from escaping and mixing with the air.

- Breaking the Chain Reaction: By isolating the fuel from the atmosphere, the chemical chain reaction of combustion is physically interrupted.

Why It Outperforms Other Methods in Specific Risks

During an incident investigation in a remote worker camp, I saw firsthand what happens when someone tries to use water on a grease fire. Because water is denser than oil, it sinks to the bottom, boils instantly, and expands by 1,600 times its volume, throwing burning oil into the air.

A fire blanket is the superior choice in these scenarios because:

- No Splashing: It does not displace liquid fuel, keeping the fire contained within the vessel (e.g., a frying pan or beaker).

- Thermal Insulation: The woven fiberglass acts as a heat shield, protecting the person deploying it and preventing the fire from spreading to nearby combustible surfaces.

- Passive Operation: Unlike CO2 extinguishers, which can “blow” the fire or be dissipated by wind, a blanket stays in place and maintains its seal regardless of airflow.

The Critical Cooling Phase

The most dangerous mistake I see during site drills is the “quick peek.” Just because the flames are no longer visible doesn’t mean the danger has passed.

- Heat Retention: The fuel (the oil or the fabric) remains extremely hot even after the flame is out.

- Auto-Ignition: If you remove the blanket too early, the rush of fresh oxygen can react with the superheated fuel, causing an immediate re-ignition or flashover.

- Field Rule: You must leave the blanket in place until the container is cool to the touch. In industrial kitchens, we mandate a minimum 20-minute “soak time” before the blanket is disturbed.

Material Integrity

Fire blankets are not just “heavy cloth.” They are engineered safety devices:

- Fiberglass Weave: The core is made of flexible glass fibers that can withstand temperatures exceeding $500^\circ\text{C}$.

- Fire-Retardant Coating: Many blankets are treated with a film that enhances the airtight seal and prevents the glass fibers from irritating the skin of the operator.

Field Note: If the blanket becomes saturated with oil during use, its effectiveness drops. This is why fire blankets are strictly single-use items. Once the fibers have been stressed by high heat and contaminated by fuel, they lose their structural integrity.

Types of Fire Blankets

In my years conducting site audits, I’ve often seen “domestic” blankets in heavy industrial workshops—a mismatch that can lead to catastrophic failure. Fire blankets are not “one size fits all.” They are classified based on their material composition, physical dimensions, and heat-rating capacity.

Selecting the wrong type for your specific hazard can result in the blanket melting, tearing, or failing to provide a complete seal over the fire.

1. Categorization by Material Construction

The material dictates how much heat the blanket can handle before the fibers degrade. In specialized facilities like chemical plants or refineries, the material choice is a critical compliance factor.

- Woven Fiberglass: The most common industrial type. It is flexible, highly resistant to heat, and generally rated for temperatures up to $500°C$.

- Silicone-Coated Fiberglass: These blankets feature a silicone rubber coating that improves the airtight seal and prevents the “itchy” glass fibers from irritating the skin of the responder.

- Kevlar / Aramid Fibers: Used in extreme high-heat environments (like smelting or welding). These have a much higher melting point and superior tear resistance compared to standard fiberglass.

- Wool (Treated): Historically found in older kits, these are chemically treated to be fire-retardant. While rare now, they are occasionally still used as “emergency wraps” for personnel in specific sectors.

2. Categorization by Application & Size

When I’m drafting a Fire Risk Assessment (FRA), I match the blanket size to the potential surface area of the hazard. A blanket that is too small is useless; a blanket that is too large in a cramped space can become a trip hazard.

| Type | Common Sizes | Typical Application |

|---|---|---|

| Small (Light Duty) | 1.0m×1.0m | Small kitchenettes, laboratory beakers, office breakrooms. |

| Medium (Standard) | 1.2m×1.2m | Commercial deep fryers, workshop workbenches, small chemical drums. |

| Large (Heavy Duty) | 1.8m×1.2m to 1.8m×1.8m | Personnel wrap, welding bays, large industrial machinery. |

3. Specialized Industrial Blankets

Beyond the standard kitchen-style “pull-tab” canisters, certain high-risk industries require specialized configurations:

Welding & Cutting Blankets

These are not designed to “smother” a fire after it starts, but to prevent one. They are draped over flammable equipment or pipes during “hot work” to catch sparks and slag. They are significantly thicker and more durable than standard fire blankets.

Personnel/Life-Safety Blankets

Usually stored in quick-release “pillows” or wall-mounted boxes near emergency showers. These are sized specifically to wrap around a human body. In my experience, these are vital in environments where chemical flash-fires or static-ignited clothing fires are a risk.

EV (Electric Vehicle) Fire Blankets

A newer addition to the HSE landscape. Because lithium-ion battery fires are extremely difficult to extinguish, these massive blankets (often $6\text{m} \times 9\text{m}$) are used to isolate a burning vehicle, containing the flames and toxic smoke to prevent spread to nearby structures.

4. Certification Standards

As an HSE practitioner, I don’t trust a blanket unless it carries a verified certification mark. This ensures the “type” you are buying has actually been lab-tested against real flames.

- BS EN 1869: The European standard for fire blankets, widely used globally.

- ASTM F1989: The American standard for fire blankets intended for cooking fires.

- AS/NZS 3504: The standard used across Australia and New Zealand.

Field Note: Always check the “Use By” or “Inspection” date on the canister. While the glass fibers don’t rot, the folding pattern can become “set” over years of compression, making the blanket difficult to deploy quickly in a panic.

When to Use a Fire Blanket

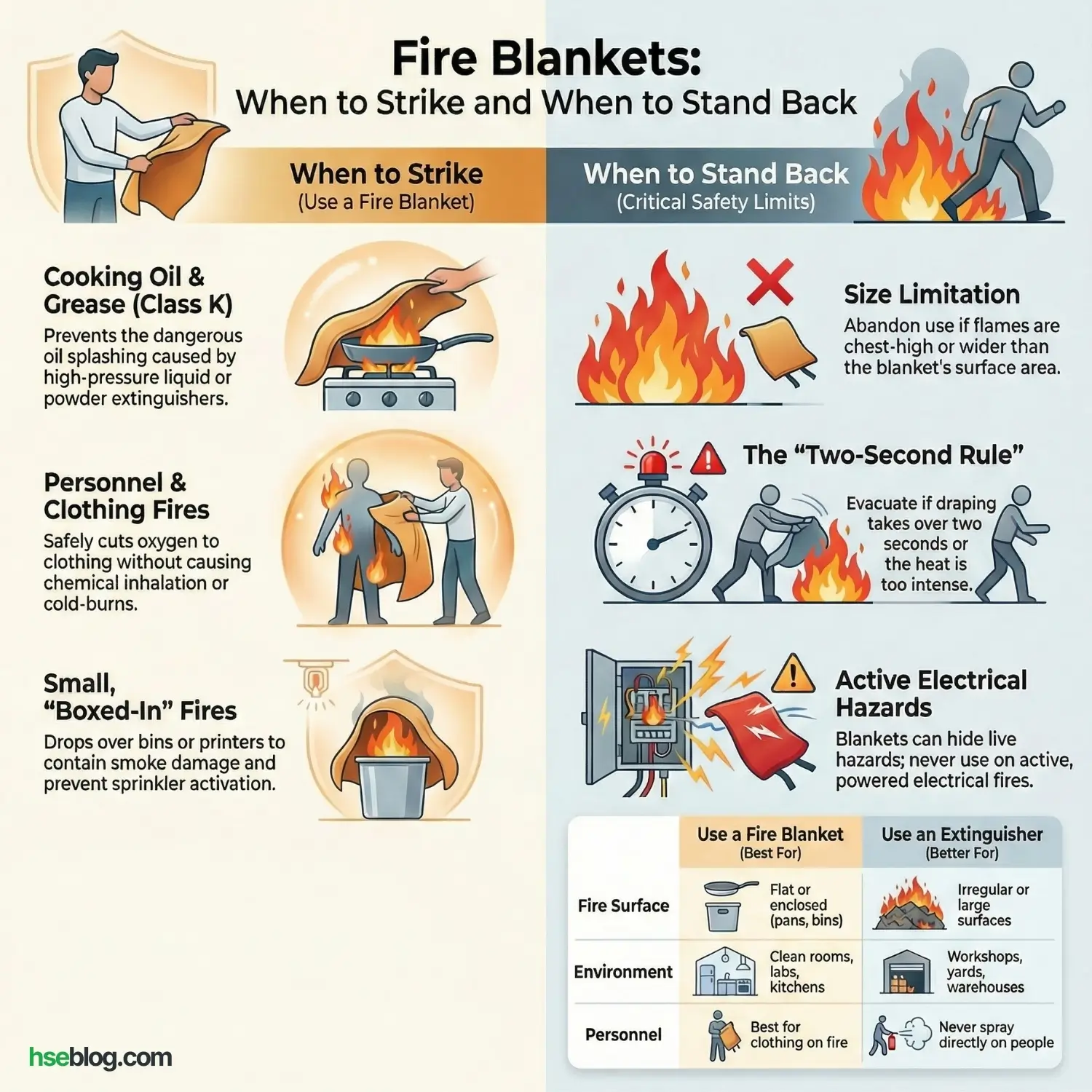

Deciding whether to reach for a fire blanket or a fire extinguisher is a split-second judgment call that can determine whether an incident is contained or becomes a disaster. In my years of conducting drills, I’ve seen that the biggest mistake isn’t using the blanket incorrectly—it’s using it for the wrong type of fire.

A fire blanket is a specialized tool. It is designed for specific, localized fires where a high-pressure extinguisher might actually cause the fire to spread or where the environment requires a clean, non-chemical suppression method.

1. Class F (K) Cooking Oil & Grease Fires

This is the “Gold Standard” use case for a fire blanket. In industrial kitchens or worker camps, large vats of oil represent a massive thermal load.

- The Scenario: A frying pan or small deep fryer ignites.

- Why a Blanket? If you use a CO2 or Dry Powder extinguisher, the high-pressure blast can splash the burning oil onto the operator or surrounding walls. The blanket “sets” on top of the liquid, killing the flame without moving the fuel.

- The Limit: If the oil is overflowing the container or the fire has spread to the exhaust hoods, the blanket is no longer sufficient.

2. Personnel / Clothing Fires

When a person’s clothing catches fire, the “Stop, Drop, and Roll” method is the first line of defense, but a fire blanket is the most effective external intervention.

- The Scenario: A lab technician or welder suffers a flash fire.

- Why a Blanket? Wrapping the victim in a fire blanket immediately cuts oxygen to the clothing. Unlike extinguishers, it won’t cause respiratory distress from chemical inhalation or cold-burns (in the case of CO2).

- Field Rule: Always wrap from the neck down to prevent pushing flames and smoke up toward the victim’s face.

3. Small, Contained Solid Fires (Class A)

Fire blankets are highly effective for fires that are physically “boxed in.”

- The Scenario: A wastepaper bin, a small piece of laboratory equipment, or a desktop printer catches fire.

- The Advantage: By dropping the blanket over the bin or device, you contain the smoke and soot damage to that single item, preventing the building’s smoke detectors or sprinklers from triggering unnecessarily across the entire floor.

4. Hot Work Protection (Pre-emptive Use)

In my inspections of welding bays, fire blankets are often used as a preventative measure rather than a reactive one.

- The Scenario: Performing “Hot Work” (welding, grinding, cutting) near fixed assets that cannot be moved.

- The Application: Draping heavy-duty blankets over sensitive cables, wooden structures, or machinery to catch “slag” and sparks. This prevents the fire from starting in the first place.

When NOT to Use a Fire Blanket

Knowing when to walk away is just as important as knowing when to engage. I’ve seen “brave” workers try to blanket a fire that was far too large, resulting in severe hand burns.

- Fire Larger than the Blanket: If the flames are licking higher than your chest or the surface area is wider than the blanket, do not attempt suppression.

- Electrical Fires (Active): While the fiberglass is non-conductive, a blanket won’t stop the electricity from arcing. If the power is still on, the blanket could hide a “live” hazard.

- Out-of-Control Fires: If the fire has spread to the walls, ceiling, or nearby combustibles, your only job is to trigger the alarm and evacuate.

Decision Matrix: Blanket vs. Extinguisher

| Feature | Use a Fire Blanket | Use an Extinguisher |

| Fire Type | Small, contained (pan, bin). | Spreading or vertical fires. |

| Surface | Flat or enclosed. | Irregular or large surfaces. |

| Environment | Clean rooms, labs, kitchens. | Workshops, warehouses, yards. |

| Personnel | If clothing is on fire. | Never spray directly on a person. |

Field Note: I always teach my teams the “Two-Second Rule.” If it takes you more than two seconds to figure out how to drape the blanket, or if you feel the heat is too intense to get within arm’s reach, abandon the attempt. Your life is worth more than the equipment you are trying to save.

How to Use a Fire Blanket Effectively

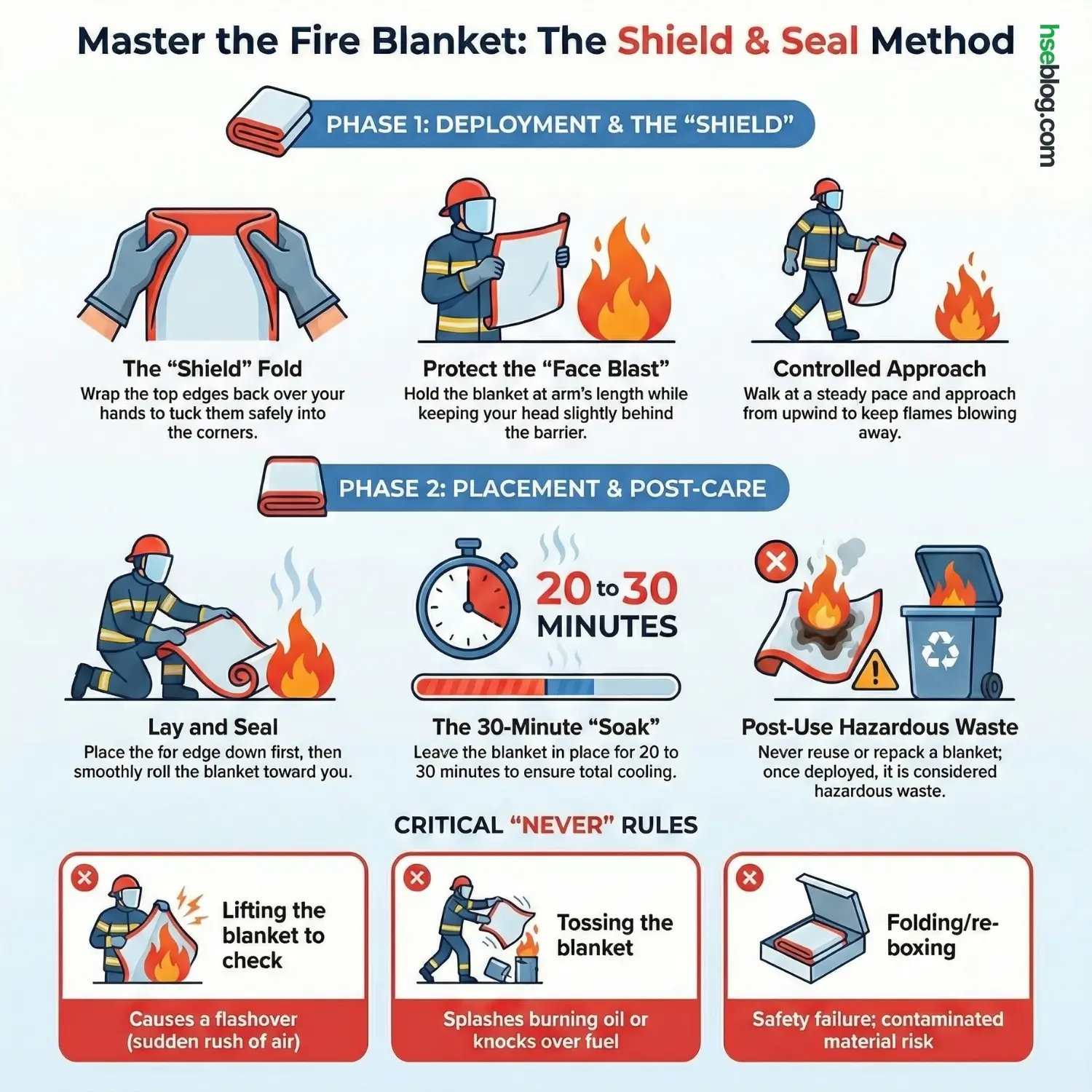

Deployment is where theory meets high-stress reality. I’ve witnessed drills where even seasoned supervisors fumbled the pull-tapes because they hadn’t practiced the “shield” technique. You don’t “throw” a fire blanket like a tablecloth; you deploy it as a protective barrier between you and the thermal energy.

In the field, we teach a specific sequence of muscle memory to ensure that the fire is suppressed without the operator sustaining secondary burns to the hands or face.

1. The Release and Grip (Protecting Your Hands)

The most common injury during fire blanket use is burnt knuckles. This happens when the user holds the blanket like a sheet, exposing their fingers to the rising heat.

- The Pull: Reach for the two tapes protruding from the bottom of the canister. Pull them hard and straight down to release the blanket.

- The “Shield” Fold: Immediately wrap the top edges of the blanket back over your hands. Your hands should be “tucked” into the corners of the blanket.

- The Barrier: Hold the blanket at arm’s length in front of you. Keep your head slightly behind the blanket to protect your face from the initial heat blast.

2. The Approach (The “No-Run” Zone)

Panic causes people to rush, which can create a gust of air that fans the flames.

- Check the Path: Ensure you have a clear escape route behind you before moving toward the fire.

- Controlled Stance: Walk toward the fire at a steady pace. Keep the blanket low enough to see over the top, but high enough to shield your chest and neck.

- Wind Direction: If you are outdoors or in a ventilated workshop, approach from upwind so the flames are pushed away from you, not toward you.

3. The Placement (The “Lay and Seal”)

The goal is to eliminate air gaps. If oxygen can get under the corner, the fire will continue to breathe.

- Far Edge First: Place the far edge of the blanket down on the far side of the container (pan, bin, or equipment) first.

- Smooth Roll: “Roll” the rest of the blanket toward you until the entire fire is covered.

- Don’t Toss: Never throw the blanket. Tossing it can splash burning oil or knock over the container, turning a localized fire into a floor-wide emergency.

4. Post-Deployment Actions

Dropping the blanket is only half the job. The environment is still hazardous until the “Fuel-Heat” connection is severed.

- Isolate the Fuel: Once the blanket is in place, reach for the power switch or gas valve to turn off the heat source—but only if you can do so without reaching over the blanket.

- The “Soak” Time: Leave the blanket in place for at least 20 to 30 minutes.

- Call it In: Even if the fire appears out, contact the fire department or site emergency team. Smoldering embers inside a piece of machinery can re-ignite hours later.

Special Procedure: Personnel on Fire

If a colleague’s clothing is on fire, the approach changes slightly to account for human movement and shock.

- Command: Shout “Stop, Drop, and Roll” to the victim.

- The Wrap: Wrap the blanket around them tightly to exclude air.

- Neck Down: Start the wrap from the shoulders/neck downward. This prevents the “chimney effect,” where heat and smoke are funneled upward into the victim’s mouth and nose.

- Medical: Seek immediate medical attention. Do not attempt to remove the blanket if it has stuck to the skin; let the paramedics handle it.

The “Never” List (Field Rules)

Blockquote: “In safety, a ‘near-miss’ is a gift. If you use a blanket and it fails, don’t try to fix it. Get out.”

- NEVER lift the blanket to check if the fire is out. The rush of air will cause a flashover.

- NEVER use the blanket if it is contaminated with oil from a previous spill.

- NEVER try to fold it back up and put it in the box after use. It is now hazardous waste.

Maintenance and Replacement of Fire Blankets

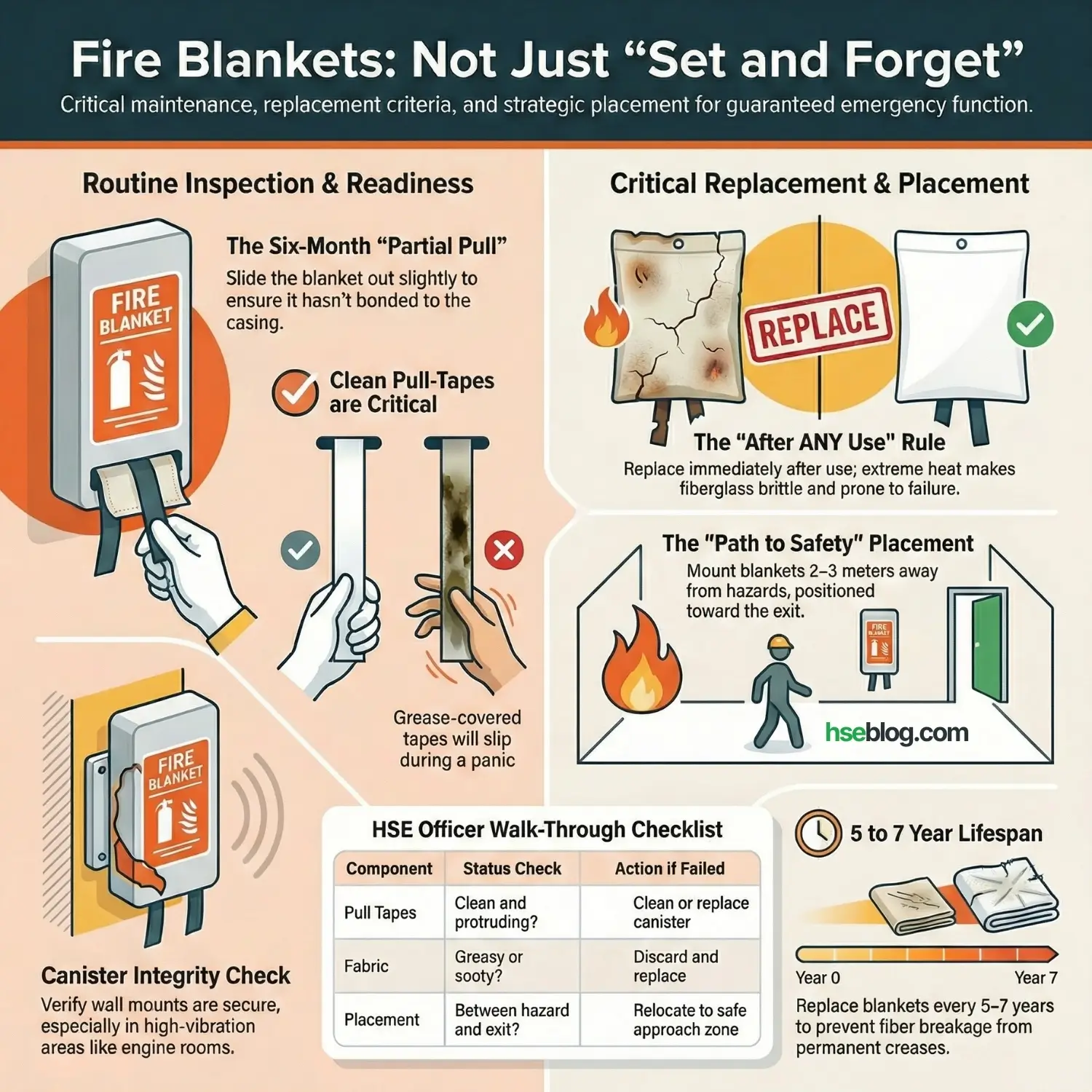

In my experience as a Lead Auditor, the fire blanket is the most neglected piece of life-safety equipment on-site. Because it doesn’t have a pressure gauge like an extinguisher, people assume it’s “set and forget.” I’ve opened canisters during inspections only to find blankets that were used, greased up, and stuffed back inside—effectively creating a fire-starter rather than a fire-extinguisher.

Maintenance isn’t just about the blanket itself; it’s about ensuring the deployment system is flawless. If those pull-tapes fail or the blanket is stuck in the housing, your emergency response is dead before it starts.

1. Routine Inspection Protocol

I mandate a monthly visual inspection and a more rigorous annual check. You are looking for any factor that could hinder deployment or compromise the material’s integrity.

- Canister Integrity: Ensure the wall-mounted housing is secure and not cracked. In high-vibration environments like engine rooms, check that the mounting hasn’t shaken loose.

- The Pull-Tapes: These must be visible, clean, and hanging freely. If they are tucked inside or covered in kitchen grease, they will slip through a responder’s fingers during a panic.

- Deployment Check: Every six months, I recommend a “partial pull.” Slide the blanket out just enough to ensure it hasn’t become “bonded” to the plastic casing due to heat or chemical vapors.

- Cleanliness: If the blanket is located in a kitchen or machine shop, ensure the outer casing is free of oil. Oil seeping into the canister can contaminate the fiberglass, making it flammable.

2. When to Replace a Fire Blanket

There is a common misconception that fire blankets last forever. In reality, several factors require you to decommission a blanket and order a replacement immediately.

- After ANY Use: This is a non-negotiable field rule. Even if the blanket looks “clean,” the extreme heat of a fire causes the fiberglass to become brittle. It loses its tensile strength and will fail if used a second time.

- Contamination: If the blanket has been soaked in oil, chemicals, or even heavy dust, replace it. Contaminants can act as a “wick,” allowing the fire to burn right through the blanket.

- Fraying or Tears: Any physical damage to the weave allows oxygen to leak through. A blanket with a 1-inch tear is no longer a “smothering” tool; it’s a chimney.

- Age: While the fiberglass doesn’t rot, most manufacturers recommend replacement every 5 to 7 years. Over time, the way the blanket is folded creates permanent creases that can lead to fiber breakage.

3. Strategic Placement Rules

Maintenance also includes ensuring the blanket stays where it belongs. I’ve seen blankets moved behind stacks of boxes or hidden inside cupboards.

- The “Path to Safety” Rule: Never mount a fire blanket directly above a stove or a high-risk machine. If that item catches fire, you cannot reach the blanket. Mount it 2–3 meters away, toward the exit.

- Height Requirements: It should be mounted at a height where the shortest member of your staff can reach the pull-tapes (typically 1.5 meters from the floor).

- Signage: A fire blanket is often small and white or red. In a smoke-filled room, it disappears. Every blanket must have a high-visibility, photoluminescent (glow-in-the-dark) sign mounted above it.

Summary Checklist for HSE Officers

| Component | Status Check | Action if Failed |

| Pull Tapes | Are they clean and protruding? | Clean or replace canister. |

| Seal | Is the tamper seal intact? | Inspect blanket for hidden use. |

| Fabric | Any signs of “greasiness” or soot? | Discard and replace. |

| Mounting | Is it between the hazard and the exit? | Relocate to a safe approach zone. |

Field Note: During your next safety walk-through, ask a random worker to demonstrate how they would pull the blanket. If they hesitate or struggle with the container, your maintenance program needs to include a practical training session. Equipment is only as good as the hands that use it.

Conclusion

In the high-stakes environment of a job site, a fire blanket is often the difference between a “near-miss” and a “fatality.” It is a tool that demands respect and proper technique. We must move away from the mindset that safety equipment is just a compliance checkbox; these tools are designed to protect the most valuable asset on any site—the people.

Always remember: if a fire is larger than the blanket, or if you feel the heat is too intense to approach, abandon the attempt. Your life is worth more than any piece of equipment.