What is A Fire Suppression System?

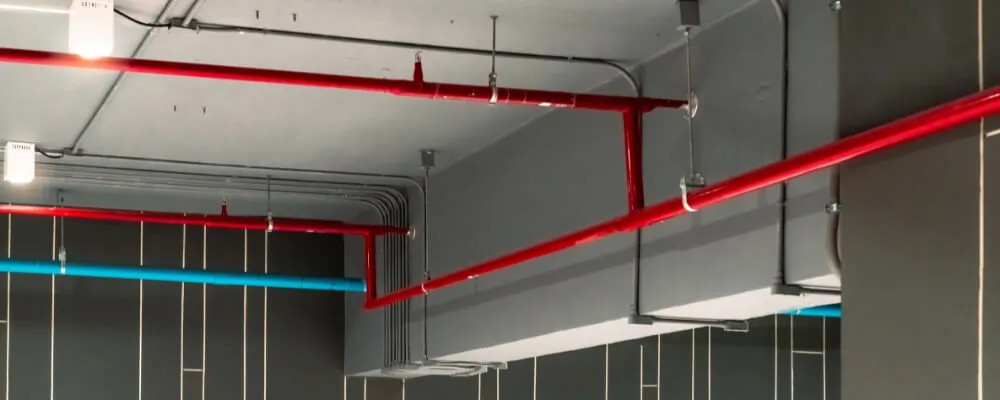

A fire suppression system combines devices and equipment to detect and combat fires, often through water, gas, or other chemicals. These systems are engineered to activate automatically upon detecting a fire, deploying suppressants to halt the spread of flames and mitigate damage.

Unlike a simple fire extinguisher that requires manual operation, fire suppression systems are typically integrated with smoke or heat detectors and alarm systems. When a fire is detected, the system dispenses its suppressant material, such as water, foam, or gas, to quench it. In high-risk commercial environments like server rooms or kitchens, these systems prioritize human safety and the protection of valuable assets.

Benefits Of Using An Automatic Fire Suppression System

Automatic fire suppression systems offer numerous benefits when protecting people, property, and assets. Here’s an in-depth look at the advantages of using an automatic fire suppression system:

- Rapid Response: One of the primary benefits of automatic fire suppression systems is their quick reaction time. As soon as the system detects a potential fire, it activates immediately, often catching the fire in its initial stages and preventing it from spreading further. This rapid response can be crucial in minimizing damage and saving lives.

- Reduced Human Intervention: Automatic systems operate without the need for human intervention. This is beneficial because it eliminates the potential for human error during activation, ensuring that the system functions effectively even if no one is present or if individuals are incapacitated due to smoke or other hazards.

- Continuous Protection: Automatic fire suppression systems provide 24/7 protection. Whether during business hours or in the middle of the night, these systems are always on guard, ensuring constant safety for premises and assets.

- Flexibility in Choice of Suppressants: Automatic systems can be designed to release various suppression agents, from water and foam to clean agents and gases. This flexibility allows the system to be tailored to a particular environment’s needs and risks.

- Reduced Damage and Downtime: By detecting and combating fires in their early stages, automatic systems help limit the damage caused by both the fire and the suppressant. This can reduce repair costs and decrease the downtime for businesses, allowing them to resume normal operations more quickly.

- Enhanced Safety: Automatic systems reduce the need for individuals to combat fires manually, thus minimizing the risk of injury. Moreover, these systems often come with alarms and notification mechanisms that alert occupants, giving them more time to evacuate safely.

- Insurance Benefits: Many insurance companies recognize the benefits of automatic fire suppression systems. Installing such a system can lead to reduced insurance premiums for property owners, as the presence of the system decreases potential loss risks.

- Environmentally Friendly Options: Modern automatic fire suppression systems are moving towards eco-friendly suppressants with minimal environmental impact. This ensures safety and aligns with global efforts to reduce harmful emissions and protect the ozone layer.

- Comprehensive Coverage: Automatic systems can cover every nook and cranny of a facility, ensuring that even hidden or hard-to-reach areas are protected.

- Cost-Efficiency: While the initial investment for an automatic fire suppression system can be significant, the potential savings in avoided damages, reduced downtime, and possibly lowered insurance premiums can make it a cost-effective choice in the long run.

In summary, automatic fire suppression systems provide a robust and efficient solution for fire protection. Their rapid response, continuous monitoring, and tailored approach make them invaluable for safeguarding lives and assets.

How Do Fire Suppression Systems Work?

Fire suppression systems detect and respond to fires early, aiming to control, reduce, or extinguish the blaze. Here’s a general overview of how they function:

1. Detection

The foundation of an effective fire suppression system lies in its ability to swiftly and accurately detect the early signs of a fire. Detection operates as the sensory network of the system, constantly vigilant and ready to react. Various sensors and detectors calibrated to respond to specific indicators are strategically dispersed throughout a facility.

Heat sensors, for instance, are designed to pick up abrupt spikes in temperature or recognize sustained high temperatures indicative of a potential fire. On the other hand, smoke detectors utilize advanced technologies to identify the presence of smoke particles in the air.

These detectors often incorporate either ionization, which is more responsive to rapidly flaming fires, or photoelectric methods, more attuned to smoldering fires that generate larger smoke particles. The sophistication and sensitivity of these detection devices are paramount, ensuring that the system distinguishes between genuine threats and benign events, thereby minimizing false alarms.

2. Activation

Following the detection phase, the fire suppression system swiftly transitions into activation mode. This stage serves as a two-pronged response to the impending threat. Firstly, an alarm is set off, which can be audibly and visually experienced. Audible alerts like sirens or buzzers are designed to be loud and piercing, ensuring they capture the attention of all occupants, even those in deep sleep or noisy environments.

Concurrently, visual indicators, such as flashing lights, complement the sound, providing an unmistakable signal of danger, especially in areas where the audible alarm might be muffled or for individuals with hearing impairments.

These alarms serve the crucial role of alerting the building’s occupants to evacuate or take other necessary safety measures. Secondly, the activation phase signals the system to discharge the chosen suppression agent, water, gas, foam, or chemicals. This automatic release is designed to rapidly counteract and suppress the fire, preventing its spread and minimizing damage. The seamlessness of this transition from detection to activation is essential for the safety of the building’s occupants and infrastructure.

3. Dispensation of Suppressant

The crux of a fire suppression system’s effectiveness lies in the timely and efficient dispensation of its suppressant. The choice of suppressant is often contingent on the environment it protects and the nature of potential fires. Water-based systems, a staple in many facilities, release water over the ignited area.

The primary function of the water is twofold: it not only cools the environment rapidly, dousing the flames, but also saturates materials, rendering them less conducive to combustion. In stark contrast, gas-based systems operate on a different principle.

Agents like Novec 1230 or inert gases like IG-55 are rapidly introduced into the fire zone. Their action is not to cool but to either displace oxygen, essential for combustion or disrupt the chemical reactions sustaining the fire. Kitchens and areas prone to liquid-based fires often employ chemical foam systems.

Like the fire blankets, the foam swiftly engulfs the flames, depriving them of oxygen and cooling the hot liquids, preventing re-ignition. Lastly, with their fine particulate suppressants, dry chemical systems intervene at a molecular level, breaking the chain reactions that fuel the fire and halting its progress.

4. Post-Activation Measures

The immediate aftermath of a fire suppression system’s activation is as crucial as the initial response. After the fire threat is mitigated, the focus shifts to ensuring the safety and well-being of the environment and its occupants. Several advanced suppression systems are integrated with ventilation mechanisms.

These systems activate soon after the fire is suppressed to evacuate residual smoke, which might pose inhalation hazards or impair visibility. This becomes even more vital if the suppressant used could be potentially harmful when inhaled.

The ventilation aids in rapidly restoring the environment to its normal state, ensuring any lingering suppressants, especially in the case of gas-based systems, are expelled. These post-activation measures also assist in assessing the system’s readiness for future incidents, ensuring that any used suppressant tanks are replaced, and the system is reset, ready to respond to subsequent threats.

Types Of Fire Suppression System

Fire suppression systems are categorized based on the agents they use to suppress or extinguish fires. Here’s an overview of the main types of fire suppression systems:

1. Water-Based Suppression Systems

Sprinkler Systems

Renowned for their ubiquitous presence in various establishments, sprinkler systems are a frontline defense against fires. The sensors in these systems are highly sensitive to temperature variations. When the surrounding environment’s temperature exceeds a predetermined threshold, the heat causes the sprinkler heads to activate, releasing water to douse the flames. T

Their design is intentional; only the sprinkler heads subjected to the high temperatures release water, ensuring water damage is localized to the fire’s immediate vicinity. This strategic approach makes them an optimal choice for commercial buildings, homes, and industrial areas.

Water Mist Systems

The innovation behind water mist systems lies in their ability to produce an ultra-fine mist. This mist absorbs heat, rapidly cooling the fire’s environment. By producing mist, they also displace the surrounding oxygen, essential for combustion.

Their dual-action of cooling and oxygen displacement renders them especially useful in settings where conventional water sprinklers might cause undue water damage.

2. Clean Agent Suppression Systems

Gaseous Systems

Gaseous systems like FM-200 or Novec 1230, alongside inert gases like argon or nitrogen, are sophisticated fire deterrents. Their operation principle revolves around two key strategies: heat absorption and oxygen displacement. This makes them especially valuable in data centers where water can severely damage electronic equipment. Their deployment ensures fires are quelled without leaving residue or causing water damage.

Carbon Dioxide (CO2) Systems

The CO2 systems stand out due to their unique fire-suppressing mechanism. By releasing carbon dioxide, they rapidly reduce the oxygen level in the immediate environment, suffocating the fire. This characteristic makes them particularly useful in industrial scenarios, especially where traditional fire suppressants might harm the processes or equipment.

3. Foam Suppression Systems

Foam suppression systems harness the combined power of water and specially formulated foam concentrates to produce a dense, enveloping foam solution that plays a pivotal role in fire defense. When unleashed upon a fire, this foam acts like a protective shield, rapidly spreading across the fire’s surface. By doing so, it performs a crucial dual function: it sequesters the flames, cutting off the vital oxygen supply needed for combustion, and it also aids in cooling the affected area, further hampering the fire’s ability to sustain itself or spread.

Such systems are not just efficient, but they are a necessity in environments with heightened fire risks, especially those involving flammable liquids. Consider the vast expanse of an airport, with its storage tanks brimming with jet fuel, or a sprawling refinery processing countless barrels of crude oil. In these settings, a minor spark can escalate into a catastrophic event.

The foam’s ability to blanket large areas swiftly and its prowess in suppressing and cooling makes it an invaluable asset. This is why airports and refineries prefer foam suppression systems, among other high-risk areas.

4. Dry Chemical Suppression Systems

Dry chemical suppression systems operate on a foundational principle: interrupting the chemical reactions that sustain and propagate fires. They deploy powdery agents, notably monoammonium phosphate or sodium bicarbonate, to achieve this. When these substances are introduced to a fire, they act as a chemical barrier, intervening and effectively disrupting the fire’s combustion process. This contains the fire and rapidly curtails its ability to spread, rendering it impotent and ensuring swift suppression.

Their distinct mode of operation makes them uniquely effective against particular kinds of fires, especially those involving flammable liquids and grease. This specificity in application can be seen in places like commercial kitchens, where the potential for grease fires is high.

Beyond the culinary world, these systems have carved out a niche in certain industrial settings where the materials processed or stored are susceptible to fires that can be quelled by these dry chemical agents. Their presence in such environments underscores their pivotal role in ensuring safety against fire hazards.

5. Wet Chemical Suppression Systems

Kitchen fires, particularly those fueled by fats and oils, present unique challenges that demand specialized solutions. Wet chemical suppression systems rise to this challenge with a distinct approach. They utilize a specially formulated liquid agent, which undergoes a rapid chemical transformation when introduced to hot oils or fats.

This change results in the formation of a soapy, foam-like substance. This substance not only smothers the immediate flames but also establishes a protective layer over the affected area, ensuring the fire remains suppressed and drastically reducing the potential for re-ignition.

Given the unpredictable and often intense nature of kitchen fires, the reliability and effectiveness of wet chemical suppression systems make them indispensable in commercial kitchen settings. Their design and functionality are tailored to combat these environments’ unique hazards. As a result, these systems are more than just protective measures; they are vital tools that ensure the safety of the kitchen equipment and the individuals operating within these spaces.

6. Aerosol Suppression Systems

Aerosol suppression systems offer a unique approach to fire control by utilizing a mist or fog composed of extremely fine particles. This carefully engineered aerosol serves two critical functions when deployed against fires.

Firstly, the sheer fineness of the particles allows for a rapid and effective cooling action. When released, these particles draw heat away from the flames, lowering the temperature of the burning materials and the immediate environment, thus making conditions less conducive for the fire to thrive.

In addition to the cooling effect, the dense fog or mist generated by the system operates as an oxygen displacer. As fires require oxygen to continue burning, the aerosol cuts off this essential element from the flames by taking up space and diluting the atmospheric concentration.

The combination of the heat absorption and oxygen displacement mechanisms makes aerosol suppression systems an innovative and powerful tool in the fight against fires, especially in areas where traditional water-based methods might be less effective or cause potential damage.

7. Special Hazard Suppression Systems

Special hazard suppression systems are bespoke fire protection solutions meticulously designed to address specific environments’ distinct and often complex fire risks. These aren’t one-size-fits-all systems. Instead, they are carefully curated based on the unique characteristics and requirements of spaces such as aircraft hangars, power plants, and data centers, each presenting its challenges regarding fire hazards.

The specific nature of potential fires, the materials present, and the environment’s operational dynamics are considered in crafting these systems. For instance, in a data center, using water-based suppression may pose risks to the equipment. So, alternative agents like inert gases or clean agents might be preferred.

Similarly, an aircraft hangar might require a different approach due to fuel and other flammable substances. Therefore, these specialized systems might employ a single agent tailored to the environment’s needs or even a combination of agents to ensure a comprehensive and effective fire response.

Difference Between A Fire Sprinkler And A Fire Suppression System

Fire sprinkler and suppression systems are designed to combat fires, but they serve slightly different purposes, utilize different mechanisms, and are used in different contexts. Here’s a detailed explanation of the differences between the two:

1. Mechanism and Agent Used

Fire Sprinkler System: This system predominantly uses water to douse fires. When the system detects a certain temperature (usually caused by a fire), the sprinkler heads release water to cool down the area and prevent the fire from spreading.

Fire Suppression System: Suppression systems can use a variety of agents, including water, foam, dry chemicals, gases, or clean agents like Novec 1230. The choice of agent depends on the specific needs of the environment and the type of fire hazards present. For example, data centers might use gas-based suppression systems because water would damage electronic equipment.

2. Activation Method

Fire Sprinkler System: Sprinkler systems are typically activated by heat. Each sprinkler head has a temperature-sensitive component, such as a glass bulb filled with a glycerin-based liquid that expands when heated. If a fire raises the temperature sufficiently, the bulb breaks, activating that particular sprinkler.

Fire Suppression System: These systems often have more complex detection mechanisms, including smoke, heat, or flame detectors. They can be designed to detect early fires and programmed for staged responses, such as sounding an alarm before deploying the suppressant.

3. Application Areas

Fire Sprinkler System: Sprinklers are commonly used in residential buildings, offices, and any environment where water can be used as the primary fire-fighting agent without causing significant damage.

Fire Suppression System: These are often found in environments where water could cause damage or exacerbate the fire, such as in data centers, kitchens, or areas with flammable liquids. They’re also used in spaces where quick evacuation, like aircraft or certain marine applications, might be challenging.

4. Water Damage

Fire Sprinkler System: One of the cons of using a fire sprinkler system is the potential for water damage, especially in areas with sensitive equipment or documents.

Fire Suppression System: Many fire suppression systems, especially those using clean agents or gases, minimize potential asset damage. They leave no residue, making them preferable for areas like server rooms.

5. Environmental and Safety Considerations

Fire Sprinkler System: Since it mainly uses water, there’s minimal environmental concern associated with its discharge, though water damage can be an issue.

Fire Suppression System: Some suppression agents, especially older halon systems, can harm the environment. Modern alternatives are often designed to be more environmentally friendly. However, certain agents might pose safety risks if people are exposed to them, necessitating proper safety protocols.

In summary, while both systems aim to mitigate the risks associated with fires, fire sprinkler systems are simpler and use water, making them suitable for general applications. In contrast, fire suppression systems offer a broader range of solutions tailored to specific environments and fire risks.

Fire Suppression System Requirements

Fire suppression system requirements vary based on regional codes, the nature of the facility or building, and the specific risks associated. However, some general requirements are widely accepted and followed around the world, based on guidelines set by organizations like the National Fire Protection Association (NFPA) in the U.S. Here’s a broad overview of the typical requirements for fire suppression systems:

1. System Design and Installation

- Systems must be designed and installed by qualified professionals.

- The design should consider the specific fire hazards of the facility, the contents, and the occupancy.

- All components must comply with recognized standards and be tested and listed for their intended use.

2. Inspection, Testing, and Maintenance

- Regular inspections are mandatory to ensure the system remains operational.

- Systems must be tested periodically to confirm they activate and function as designed.

- Maintenance should be performed as necessary and after any system activation.

3. Suppression Agent

- The chosen suppression agent must be suitable for the specific fire risk.

- Quantities of the agent should be adequate to control or extinguish a fire in the protected space.

- If the agent poses a risk to human health (e.g., certain clean agents), appropriate warnings and safety measures must be in place.

4. Detection and Activation

- Detection devices should be appropriately spaced and located to ensure early fire detection.

- Activation mechanisms, whether manual or automatic, must be readily accessible and clearly marked.

- Systems should be integrated with building fire alarm systems to notify occupants in case of activation.

5. Ventilation

- Ventilation systems should be compatible with the suppression system, ensuring that smoke, heat, and gases can be effectively vented out during a fire and suppressants aren’t prematurely vented.

6. Safety and Signage

- Warning signs should be in place if the suppression agent poses health risks.

- Clear instructions on manual activation and shutdown procedures should be posted.

- Systems that use gases or agents that can reduce oxygen levels or pose asphyxiation risks should have warnings and protocols to ensure the area is evacuated.

7. Compatibility with Building Systems

- The suppression system should be integrated with other building systems, such as HVAC or electrical systems, to ensure coordinated responses during fires.

Training: - Staff and occupants, especially in commercial settings, should be trained on the function of the fire suppression system, its activation mechanisms, and evacuation procedures.

8. Documentation

- Detailed system design, installation, inspections, tests, and maintenance records should be maintained.

- Material Safety Data Sheets (MSDS) should be available for the suppression agents.

9. Local and National Codes

- All systems must adhere to local building codes, fire codes, and any applicable national or regional standards.

It’s essential to consult with local fire departments, professional fire protection engineers, and relevant local, state, or national authorities when determining specific requirements for any facility or building.

What Industries Typically Employ Fire Suppression Systems?

Fire suppression systems are employed across various industries to safeguard assets, infrastructure, and personnel and to ensure continued operations. Some of the industries that commonly use fire suppression systems include:

- Data Centers: With vast arrays of servers and networking equipment, data centers prioritize fire safety to prevent data loss. They typically use clean agent systems or inert gases that won’t damage electronic equipment.

- Healthcare: Hospitals, clinics, and other healthcare facilities utilize fire suppression systems to protect patients, expensive medical equipment, and critical data.

- Manufacturing & Industrial: Due to the presence of machinery, combustible materials, and various processes, manufacturing plants and factories install fire suppression systems tailored to their specific risks.

- Oil and Gas: This industry’s refineries, drilling platforms, and storage facilities are at high fire risk. Foam suppression systems are often used here due to the prevalence of flammable liquids.

- Aerospace: Aircraft hangars and manufacturing facilities prioritize fire safety, given the flammable materials involved in aviation, such as jet fuel.

- Transportation: Bus terminals, railway stations, and airports use fire suppression systems to protect infrastructure and the public.

- Hospitality: Hotels, restaurants, and entertainment venues employ various fire suppression systems, with commercial kitchens particularly using wet chemical systems for grease fires.

- Retail: Large malls and retail establishments often have sprinkler systems and other fire protection measures for the safety of shoppers and inventory.

- Warehousing and Storage: These facilities, especially those storing combustible materials, need fire suppression to prevent large-scale losses.

- Marine: Ships and marine facilities, especially those carrying or processing flammable cargo, use specialized fire suppression systems suitable for maritime conditions.

- Education: Schools, universities, and other educational institutions install fire suppression systems for the safety of students, staff, and infrastructure.

- Financial Institutions: Banks and financial institutions use fire suppression to protect important documents, cash holdings, and digital equipment.

This list is not exhaustive, as fire risks can be present in almost any industry. The type and complexity of the fire suppression system will often vary based on the specific needs and risks associated with each industry.

Conclusion

The ever-present threat of fire hazards in domestic and industrial settings underscores the importance of proactive safety measures. With their varied designs and functionalities, fire suppression systems stand as silent sentinels, ever-ready to combat the unpredictable nature of flames. As we’ve traversed through their intricacies, from their operational mechanisms to the industries they serve, it’s evident that they play a pivotal role in preserving assets, both tangible and intangible.

By equipping ourselves with a deeper understanding of these systems, we enhance safety and fortify our commitment to creating environments that prioritize the well-being of all. As the adage goes, it’s always better to be safe than sorry, and in the world of fire safety, knowledge combined with action is our best defense.