In the bustling world of warehouses and industrial environments, forklifts are the mighty workhorses that keep operations running smoothly. These versatile machines are critical for quickly and efficiently moving heavy and bulky materials. However, operating a forklift requires more than just steering and lifting; it demands a keen understanding of some fundamental principles for safety and stability. Among these, the Forklift Center of Gravity concepts and the Stability Triangle stand paramount.

In this blog, we will delve into the intricacies of these two interconnected concepts that form the foundation of forklift safety. By understanding and mastering the relationship between the forklift’s center of gravity and the stability triangle, operators can minimize accidents, maximize efficiency, and create a safer workplace for all. So, strap in as we lift the veil on the science behind forklift stability and how it can be harnessed for safer and more efficient material handling.

What is The Forklift Center Of Gravity?

The forklift center of gravity is a fundamental concept that plays a pivotal role in the stability and safe operation of forklifts. To understand this, let’s break down the center of gravity and how it applies to forklifts.

Center of Gravity: A Basic Understanding

The center of gravity is a theoretical point where the total weight of an object is considered to be concentrated. For a uniform object, this point lies at its geometrical center. However, the center of gravity may not necessarily be at the geometrical center for irregularly shaped or unevenly loaded objects, such as a forklift carrying a load.

Forklift Center of Gravity

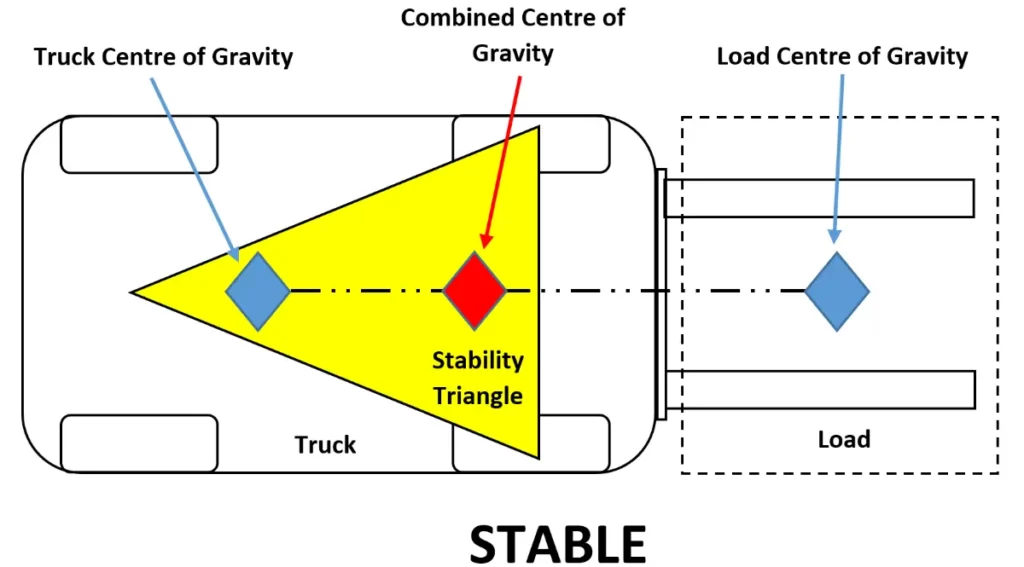

In the context of a forklift, there are two centers of gravity to consider:

- Forklift’s Own Center of Gravity: This is the point at which the weight of the empty forklift is balanced in all directions. It is determined by the construction of the forklift and its components. For example, the counterweight at the back of the forklift is designed to balance the weight of the load being lifted at the front.

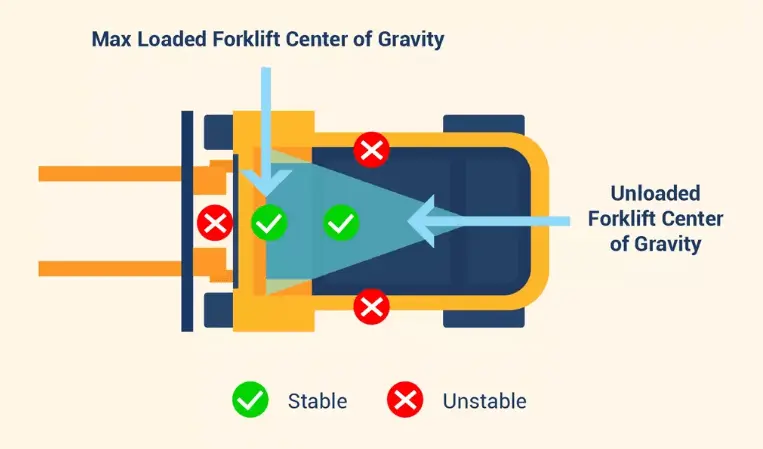

- Combined Center of Gravity: When a forklift carries a load, the center of gravity of the forklift shifts. The combined center of gravity is the point where the weight of the forklift and the load together is balanced in all directions. It’s essential for safe operation that this combined center of gravity stays within the stability triangle formed by the two front wheels and the pivot point of the rear axle.

Here are some factors affecting the combined center of gravity and how it can be managed for safe operation:

- Load Size and Weight: The size and weight of the load will affect the combined center of gravity. A heavier load will shift the combined center of gravity forward, whereas a lighter load will have less effect on it.

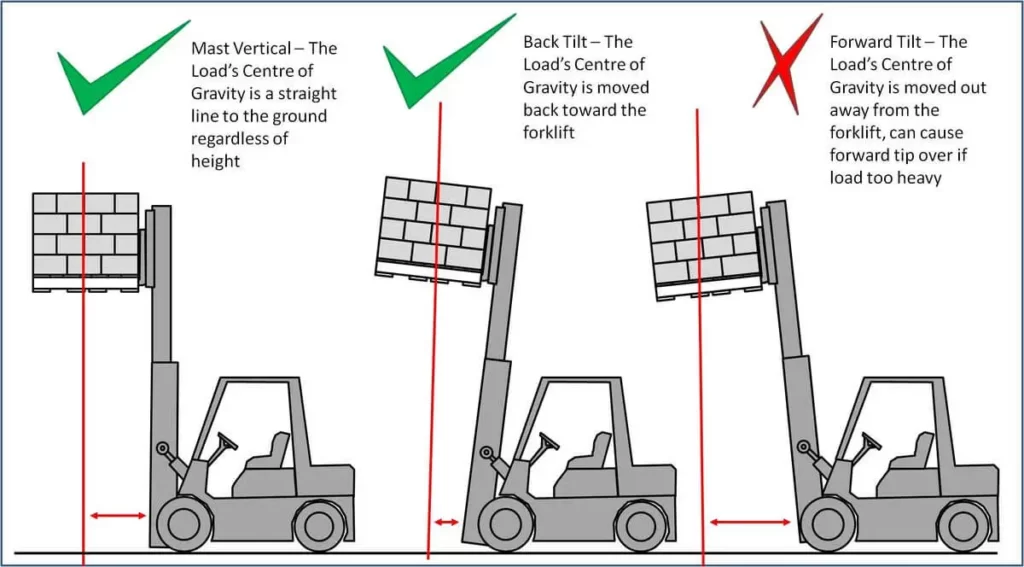

- Load Height and Tilt: The height at which the load is lifted impacts the combined center of gravity. As the load is raised, the center of gravity moves upward and becomes less stable. Similarly, tilting the load affects the center of gravity. When the mast is tilted back, the combined center of gravity shifts towards the rear, increasing stability.

- Driving and Handling: How the forklift is driven can also affect the center of gravity. Sudden stops, sharp turns, or high speeds can cause the combined center of gravity to shift abruptly, increasing the risk of the forklift tipping over.

- Terrain: Operating on an uneven surface or incline can shift the center of gravity. This is especially dangerous when carrying a load, as the combined center of gravity can easily move outside the stability triangle.

Importance of Understanding the Center of Gravity

Understanding the center of gravity is critical because it directly impacts the forklift’s stability. If the combined center of gravity moves outside the stability triangle, the forklift can tip over.

To maintain the center of gravity within the stability triangle, operators should:

- Keep the Load Low and Close to the Forklift: The closer and lower the load is to the forklift’s front wheels, the less it will affect the combined center of gravity.

- Avoid Exceeding Load Capacity: Every forklift has a rated capacity that takes into account the shifting of the center of gravity. Exceeding this capacity can cause the center of gravity to move outside the stability triangle.

- Drive Carefully: Sudden movements, turns, or stopping can cause the center of gravity to shift rapidly. Driving smoothly and carefully keeps the center of gravity stable.

- Be Mindful of Terrain: Operating on slopes or uneven surfaces can shift the center of gravity. It’s important to use caution and follow best practices when operating in such conditions.

Understanding and managing the forklift’s center of gravity is essential to ensure the safety and efficiency of material handling operations. Proper training and adherence to safety guidelines can help mitigate risks associated with the shifting center of gravity.

What is the Forklift Stability Triangle?

The Forklift Stability Triangle is a concept that illustrates the three points that keep a forklift stable during operation. Imagine a triangle where each corner represents a point of support: the two front wheels and a point where the rear axle pivots. This triangle is not a physical structure but a virtual representation to help understand how forklift stability works.

The primary purpose of understanding this concept is to ensure that the center of gravity of the forklift, along with any load it is carrying, stays within this triangular area. If the combined center of gravity moves outside the triangle, the forklift becomes unstable and risks tipping over.

Let’s break down some terms related to the stability triangle:

- Lateral Stability refers to the forklift’s ability to remain upright without tipping over to the side. Essentially, lateral stability is about preventing the forklift from rolling over sideways.

- Longitudinal Stability: On the other hand, longitudinal stability involves the forklift’s resistance against tipping over forward or backwards. It is crucial to manage the load effectively to maintain longitudinal stability.

- Dynamic Stability: Unlike the first two, which can be considered more static forms of stability, dynamic stability considers the forklift’s movements and changes in direction or speed. When a forklift moves, stops abruptly or makes sharp turns, the center of gravity can shift quickly. Dynamic stability is about managing these changes to keep the forklift stable.

- Line of Action: Imagine drawing a vertical line through the center of gravity of the forklift and load. This line is the ‘line of action’ and must stay within the stability triangle. If the line of action falls outside the triangle, the forklift will likely tip over.

- Load Center: This term refers to the horizontal distance from the forklift’s line of action to the center of gravity of the load. It’s important because the further the load is from this line, the more it can affect the forklift’s stability.

The Forklift Stability Triangle is an essential concept for ensuring the safe operation of forklifts. It helps operators understand the importance of keeping the center of gravity within a defined space to prevent tipping and accidents.

Factors Affecting Forklift Stability

- The Load: The weight and the distribution of the load are crucial. Forklifts come with data plates that provide information on their maximum load capacity and the load center. For instance, a forklift might be rated to carry 4,000 pounds at a 24-inch load center but only 2,666 pounds at a 36-inch load center. It’s imperative not to exceed these limits, as doing so could cause the forklift to become unstable.

- The Terrain: The surface on which the forklift operates significantly impacts its stability. For instance, wet or slippery floors, uneven terrain, steep inclines, or surfaces with debris can affect the forklift’s traction and balance. Operators should exercise caution and follow best practices to mitigate risks.

- Forklift Type: Different forklifts are designed for different purposes, each with unique stability characteristics. For example, a reach truck is designed for indoor use and can lift loads to significant heights, while a rough terrain forklift is better suited for outdoor construction sites.

Tips for Maintaining Forklift Stability

- Keep the Load Low: A lower load height is more stable. Ideally, the load should be 4-6 inches off the ground and tilted back towards the carriage.

- Avoid Sudden Movements: Sudden acceleration, braking, or sharp turns can cause the center of gravity to shift rapidly, affecting stability. Smooth, controlled movements are best.

- Adhere to Load Capacity Limits: Never exceed the forklift’s rated load capacity as specified on the data plate. All operators should be familiar with these limits.

- Educate and Train Operators: Proper training in forklift operation and safety is essential. Ensure that all operators are certified and understand the importance of the stability triangle.

- Regular Maintenance and Inspection: Regularly inspect and maintain the forklift to ensure it’s in good working condition. Check the tires, brakes, and hydraulic systems in a routine maintenance schedule.

Conclusion

In conclusion, grasping the Forklift Center of Gravity concepts and the Stability Triangle is an indispensable component of operating forklifts safely and efficiently. By understanding how the center of gravity shifts with load and movement and how the stability triangle serves as the zone of safe operation, forklift operators can make well-informed decisions during material handling tasks. By respecting the load limits, adapting to the terrain, and handling the forklift carefully, operators can ensure that the combined center of gravity stays within the stability triangle, drastically reducing the risk of tip-overs and accidents.

Additionally, organizations should invest in thorough training programs that emphasize the importance of these concepts to all forklift operators. The synergy between an educated operator and well-maintained equipment creates an environment where safety and productivity go hand in hand. Let the Forklift Center of Gravity and the Stability Triangle be your guiding stars as you navigate the challenging but rewarding material handling world.