I once walked onto a chaotic turnaround project at a petrochemical refinery where every worker, regardless of rank or trade, was wearing a white hard hat. When a confined space alarm triggered in Zone 4, the emergency response team lost precious minutes trying to locate the area supervisor and the fire warden among a sea of identical helmets. That lack of visual hierarchy didn’t just cause confusion; it delayed the rescue team from getting critical information about the hazardous atmosphere inside the vessel.

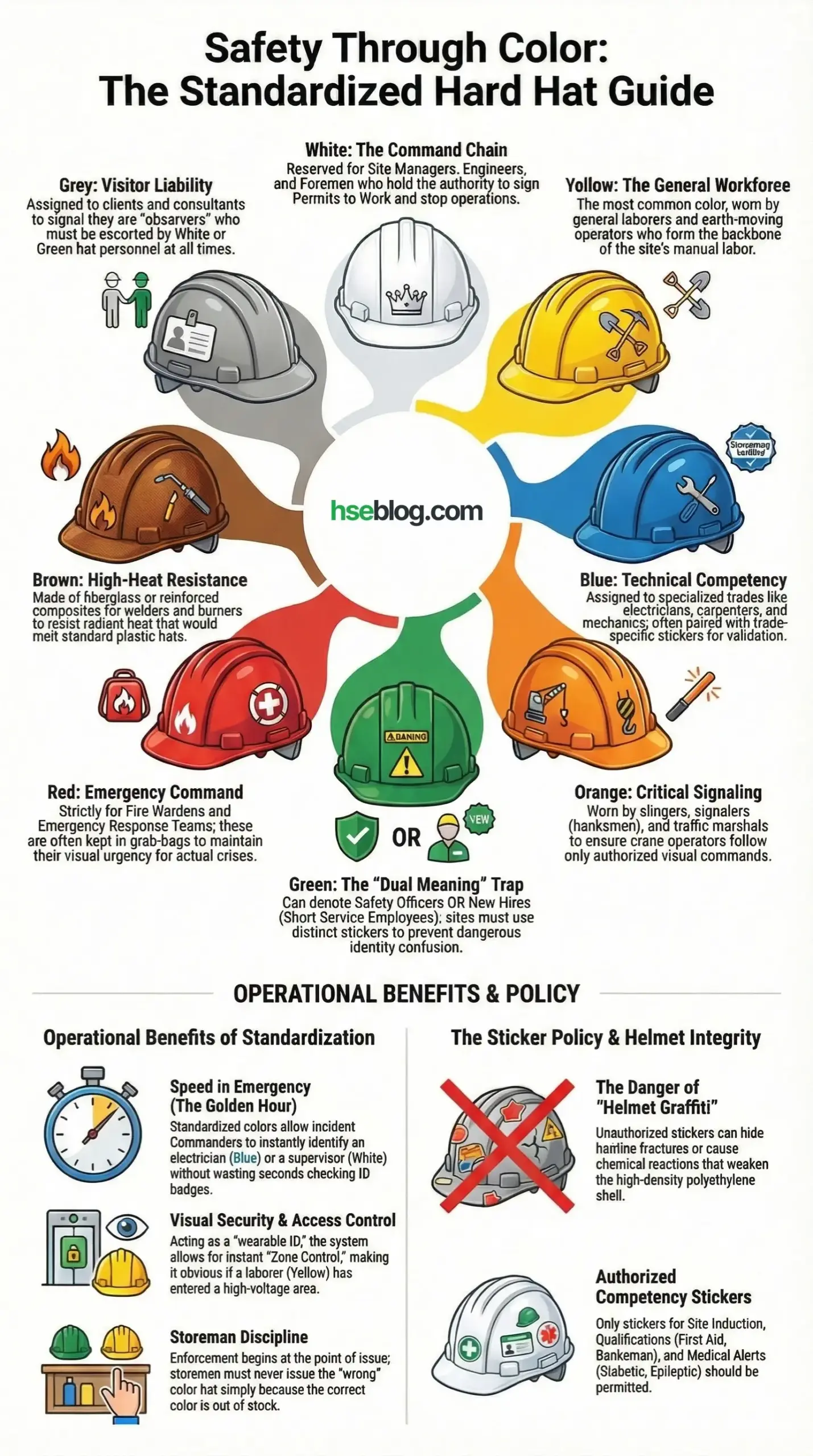

Color coding is not just about aesthetics or hierarchy; it is a critical component of Visual Management and Command & Control on a live site. In high-risk environments like construction, mining, or oil and gas, I need to know instantly who is a green-hand (new hire), who is a visitor, and who is authorized to signal a crane. While OSHA does not explicitly mandate specific colors in standard 1910 or 1926, adopting a standardized color code is industry best practice that prevents unauthorized work and streamlines emergency response.

TL;DR

- White: Typically reserved for site managers, engineers, supervisors, and foremen.

- Yellow: The most common color, strictly for general laborers and earth-moving operators.

- Blue: Assigned to technical operators like carpenters, electricians, and specialized contractors.

- Orange: Critical for lifting operations; worn by slingers, signalers (banksmen), and road crews.

- Green: Often denotes Safety Officers, though frequently used for new hires (Short Service Employees) depending on site policy.

The Logic Behind the Colors

Visual management is one of the most underrated controls in our hierarchy. When I walk onto a site with 2,000 workers, I cannot check every ID badge personally. I rely on visual cues to instantly assess the distribution of authority, technical skill, and risk.

Standardization varies—BuildUK has its specific list (e.g., black for supervisors), while ANSI in the US is more flexible—but the operational intent remains the same: Immediate Recognition.

If a site lacks a strict color code, you get “Command Blur.” This happens during incidents when workers don’t know who is in charge, or worse, during daily operations when an unskilled laborer attempts a skilled trade because “everyone looks the same.”

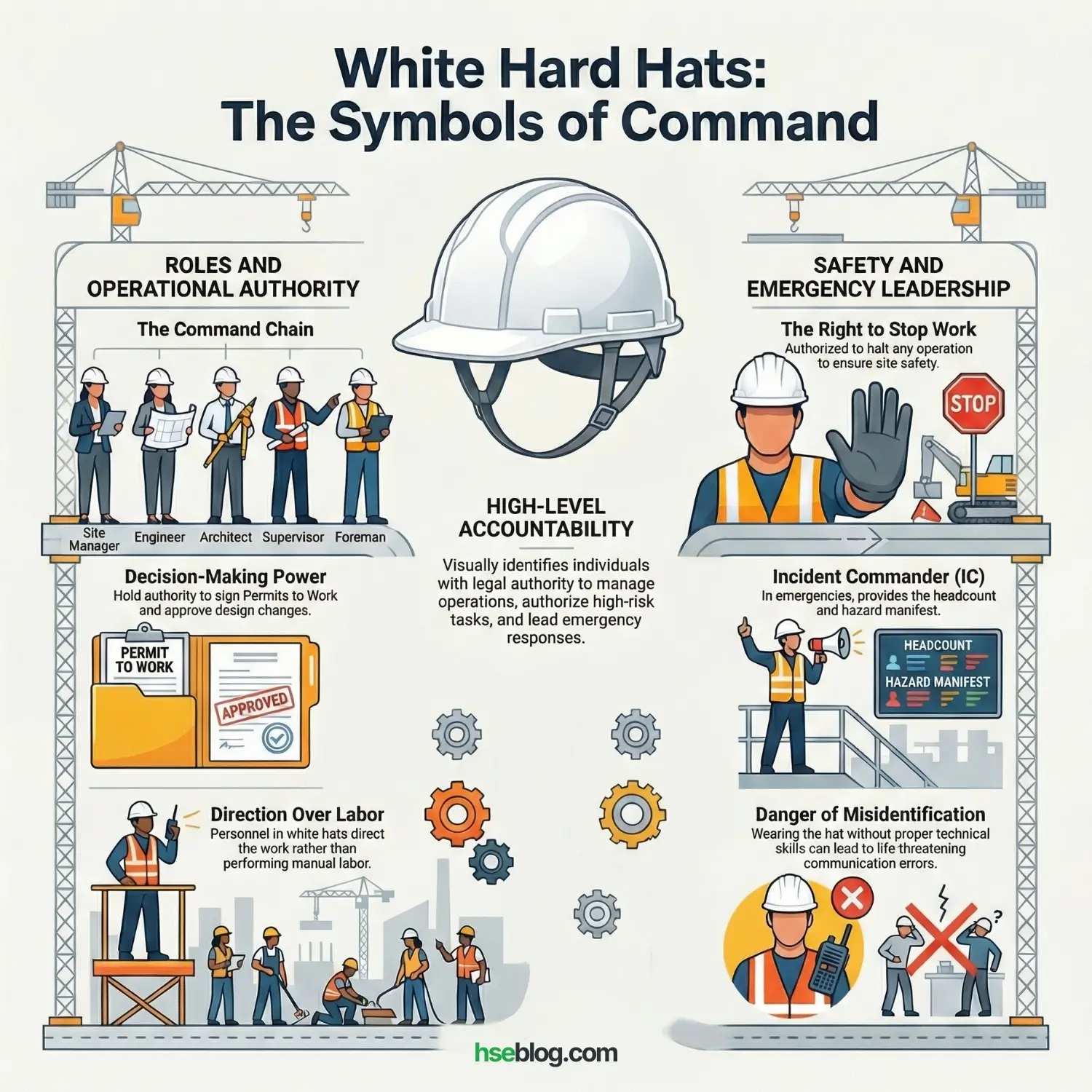

1. White Hard Hats: The Command Chain

Who: Site Managers, Engineers, Architects, Supervisors, Foremen.

The Operational Logic

White reflects heat, but more importantly, it reflects accountability. On my sites, a white hard hat is a visual signal that says, “I can sign a Permit to Work.” These are the individuals who hold the legal and operational authority to stop a job, authorize a lift, or approve a design change.

Real-World Consequence

I once stopped a lifting operation because the person directing the crane was wearing a white hat but using incorrect hand signals. It turned out to be a visiting architect trying to be helpful. This is dangerous.

- The Rule: White hats direct work; they rarely perform the manual labor.

- Emergency Context: In a rescue scenario, the Incident Commander (IC) usually wears a white hat (often with a specific vest). The Fire Team looks for the white hat to get the headcount and hazard manifest.

2. Yellow Hard Hats: The General Workforce

Who: General Laborers, Earth Moving Operators.

The Operational Logic

Yellow is the industry standard for general manpower because it offers high visibility. These workers are the backbone of the site—doing the digging, hauling, and cleaning.

The Risk Factor

The danger here is “Assumption of Incompetence.” Just because a worker wears yellow doesn’t mean they aren’t skilled, but for safety management, we must assume they are not authorized for electrical or high-risk mechanical work unless proven otherwise.

- Field Control: If I see a Yellow Hat inside a substation or handling rigging gear, I intervene immediately. They likely lack the specific training (and the insurance coverage) to be touching that equipment.

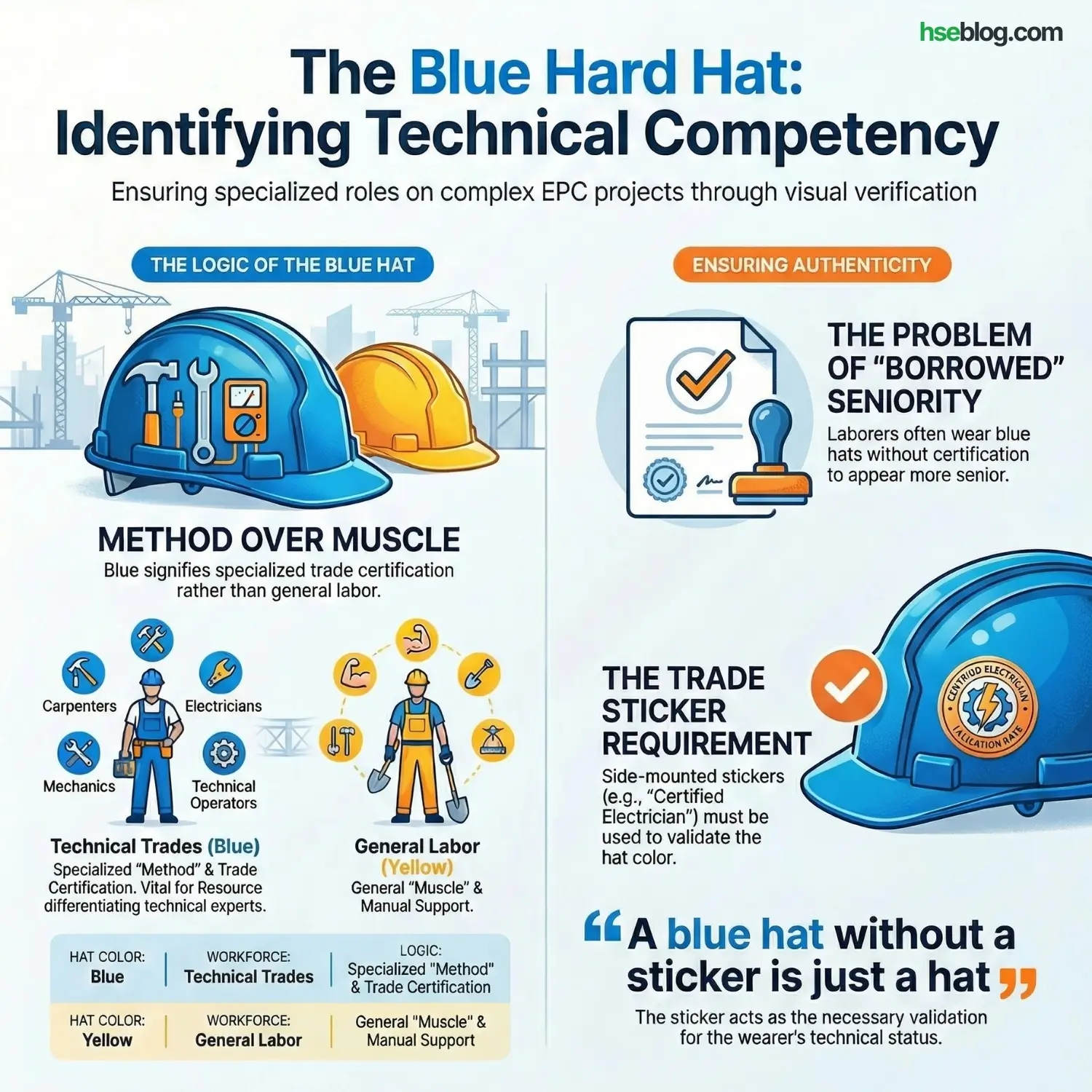

3. Blue Hard Hats: Technical Competency

Who: Carpenters, Electricians, Mechanics, Technical Operators.

The Operational Logic

Blue separates “muscle” from “method.” A blue hard hat implies a specialized trade certification. When a temporary breaker trips or a scaffold needs modification, I look for Blue.

Field Insight

On complex EPC (Engineering, Procurement, Construction) projects, differentiating Blue (Techs) from Yellow (Labor) is vital for resource allocation.

- The Problem: Laborers often “borrow” blue hats to look more senior.

- The Fix: I require trade stickers (e.g., “Certified Electrician”) on the side of blue hats. A blue hat without a trade sticker is just a hat; the sticker validates the color.

4. Orange Hard Hats: Critical Signaling

Who: Slingers, Signalers (Banksmen), Traffic Marshals.

The Operational Logic

Orange is the color of exclusive communication. In lifting operations, the crane operator is blind to much of the load. They must trust one pair of eyes. If everyone wears yellow, the operator might follow a wave from a random worker, leading to a dropped load.

Why It Matters:

- Visibility: Orange stands out against the grey of concrete, the brown of earth, and the blue of the sky.

- Authority: An Orange Hat has the authority to stop a 500-ton crane. Even the Site Manager (White Hat) generally does not give hand signals to a crane if a Banksman is present. The Orange Hat rules the lift zone.

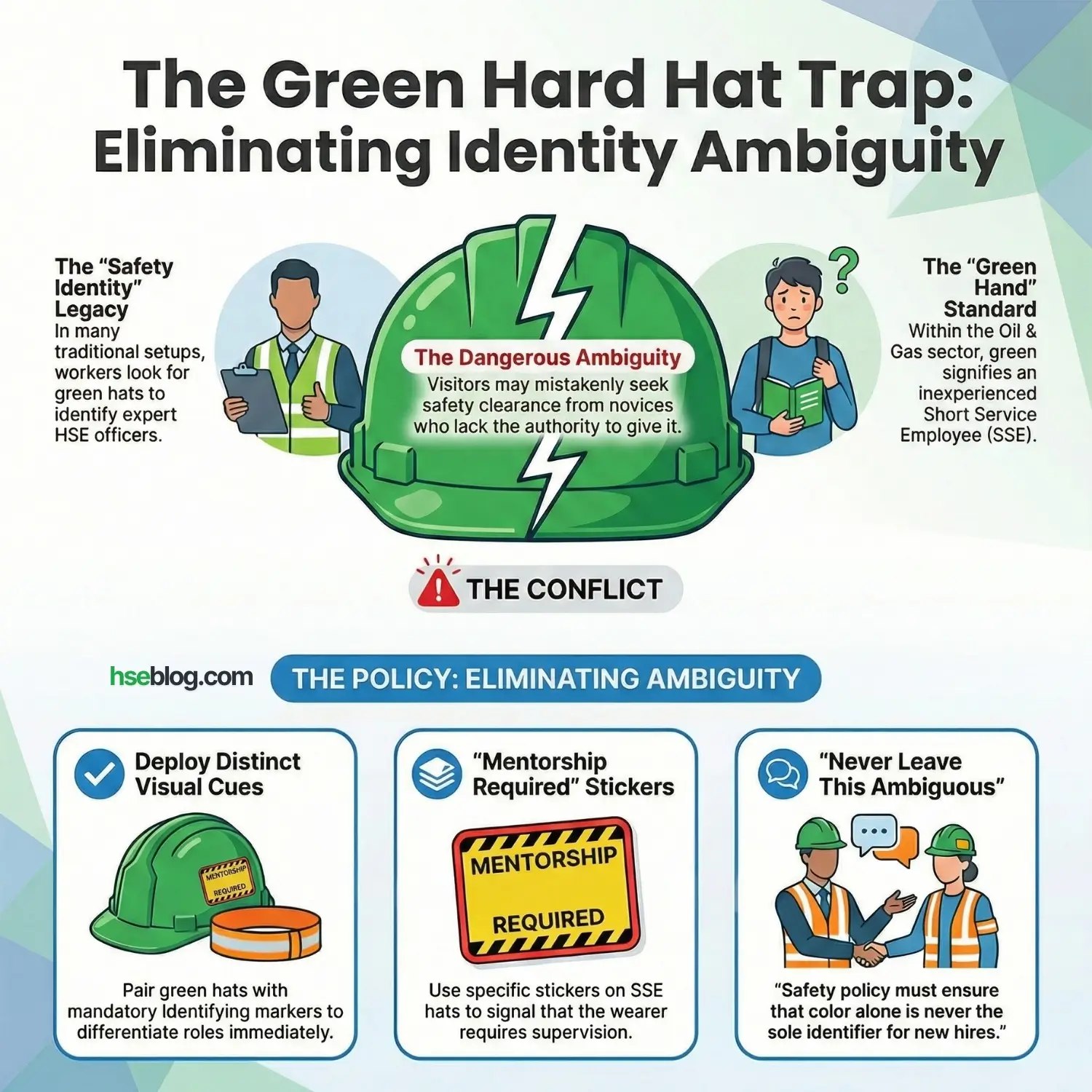

5. Green Hard Hats: The “Dual Meaning” Trap

Who: Safety Officers (HSE) OR Short Service Employees (SSE).

The Operational Logic

This is the most dangerous ambiguity in modern safety.

- Safety Identity: In many legacy setups, Green = Safety. It allows workers to easily spot the HSE officer to report hazards.

- The “Green Hand” (SSE): In the Oil & Gas sector, Green = Inexperienced (New Hire).

Field Warning

I have audited sites where new hires wore green, but visitors thought they were Safety Officers. A visitor asked a “Green Hat” if it was safe to cross a barrier. The inexperienced worker, not knowing better, said “yes.”

- My Policy: If using Green for new hires, it must be paired with a distinct visual cue, like a “Mentorship Required” sticker. Never leave this ambiguous.

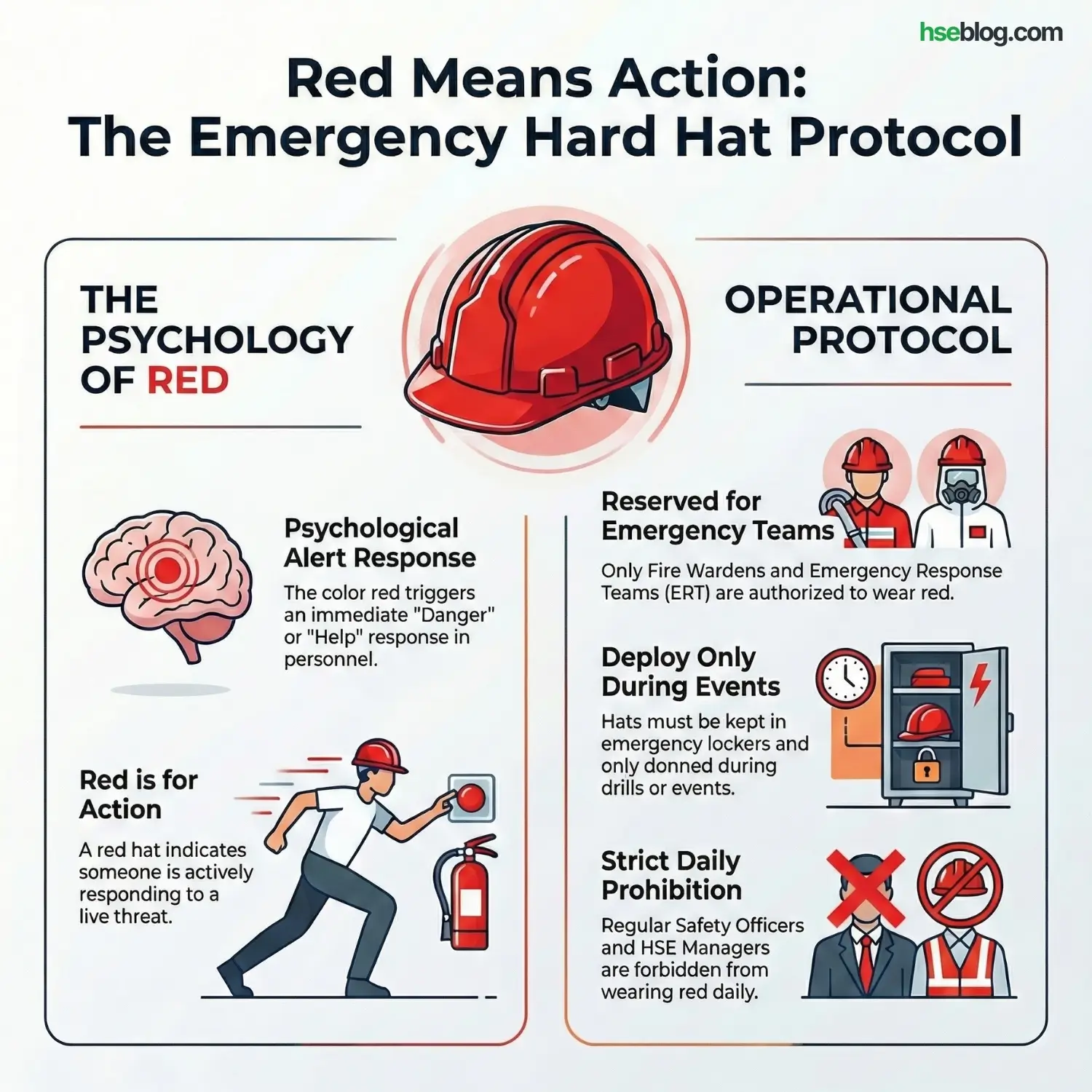

6. Red Hard Hats: Emergency Command

Who: Fire Wardens, Emergency Response Team (ERT).

The Operational Logic

Red triggers a psychological alert response. It signifies “Danger” or “Help.” These hats are often kept in grab-bags or emergency lockers and are only donned during drills or actual events.

Field Insight

I strictly forbid regular Safety Officers from wearing Red. If an HSE Manager wears Red daily, the color loses its urgency. Red is for Action. When you see a Red Hat running, you move out of the way because they are responding to a threat.

7. Brown Hard Hats: High-Heat Resistance

Who: Welders, Burners, High-Temp Operations.

The Operational Logic

This isn’t just color coding; it’s material science. Standard polyethylene hard hats can soften or deform in extreme heat. Brown hats are traditionally made of fiberglass or reinforced composites that resist high radiant heat and spatter from welding or smelting operations.

The Hazard

If I see a welder wearing a standard Yellow plastic hat while doing overhead gouging, I stop the work. The plastic can melt or burn through. Brown signifies that the PPE is rated for the thermal hazard present.

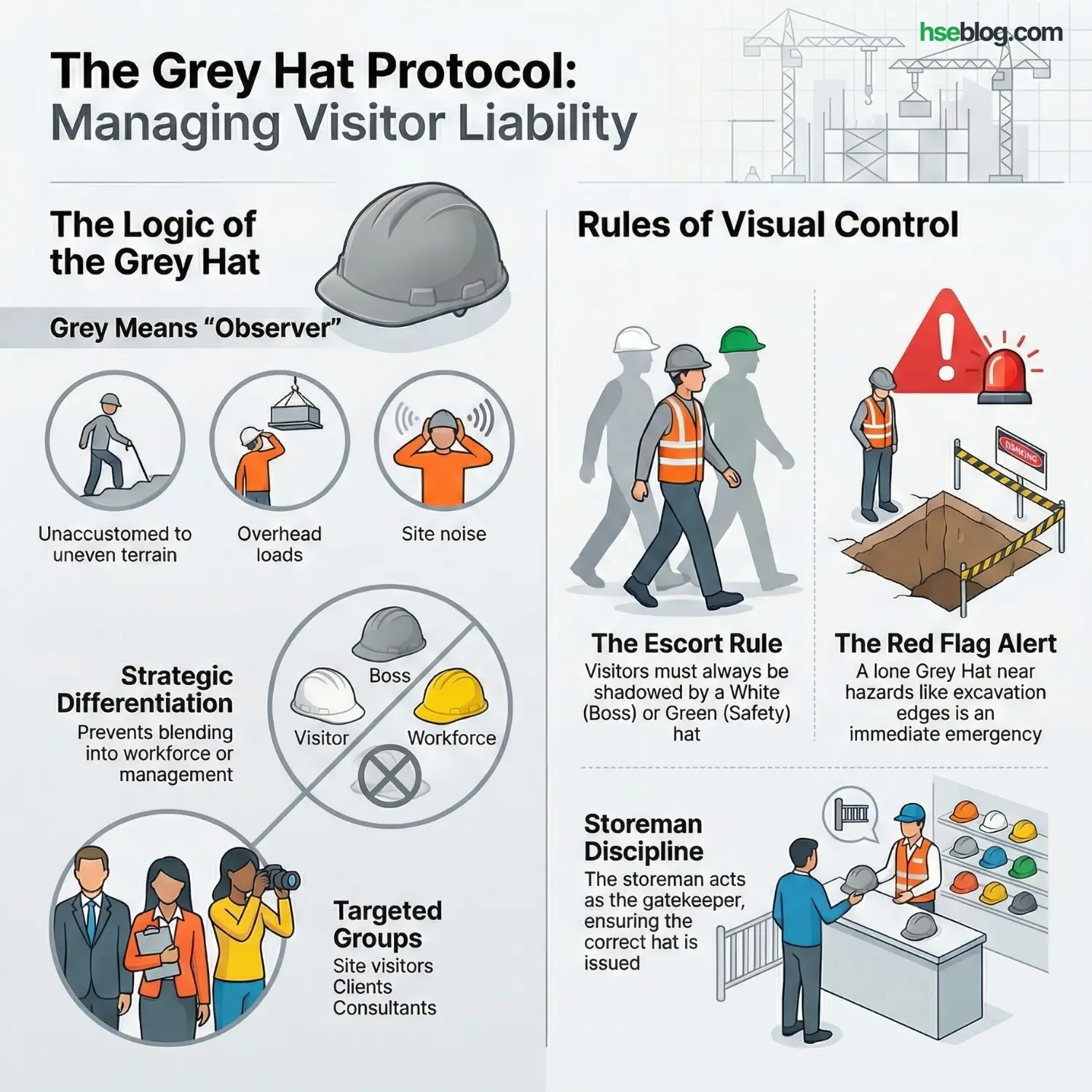

8. Grey Hard Hats: Visitor Liability

Who: Site Visitors, Clients, Consultants.

The Operational Logic

Grey implies “Observer.” Visitors are often unaccustomed to the uneven terrain, overhead loads, and noise of a site. They are a liability.

The “Escort Rule”

By assigning a dull color like Grey, we ensure they don’t blend in with the workforce, but we also distinguish them from the bosses (White).

- Visual Control: If I see a Grey Hat standing alone near an excavation edge, it is an immediate red flag. A Grey Hat must always be shadowed by a White or Green (Safety) hat. No exceptions.

Enforcing this system requires more than a memo; it requires Storeman Discipline. The storeman is the gatekeeper. They must not issue a Blue hat to a laborer just because “we ran out of Yellow.” If you break the color logic, you break the visual chain of command.

Why Standardization Matters

Many project managers view hard hat color coding as a simple housekeeping task—something to make the morning toolbox talk look organized. They are wrong.

From my experience on mega-projects like refinery shutdowns and high-rise construction, color standardization is a critical operational control. It is the difference between a controlled evacuation and a chaotic stampede. It is the difference between a secured high-voltage room and a fatal unauthorized entry. Here is why I fight for strict standardization on every site I mobilize.

1. Speed in Emergency Response (The Golden Hour)

When an incident occurs—whether it’s a gas release, a structural collapse, or a medical emergency—confusion is the enemy. We don’t have time to check badges.

- The Scenario: I once managed a site where a worker suffered an electric shock and was hung up in a harness at height. The Rescue Team arrived, but they needed the power isolated immediately before they could touch the victim.

- The Failure: Without color coding, the rescue lead had to scream, “Who here is an electrician?” into a crowd of panicked workers. Valuable seconds were wasted identifying the competent person.

- The Fix: On a standardized site, the Rescue Lead scans the crowd, spots a Blue Hat, and immediately commands: “You—Blue Hat—verify isolation on that panel now.” The visual cue bypasses the verbal confusion.

Key Takeaway: In an emergency, cognitive load is high. We revert to simple visual recognition. If I need a decision, I look for White. If I need muscle, I look for Yellow. If I need skills, I look for Blue.

2. Visual Security & Access Control

Hard hats act as a primary layer of site security, essentially a “wearable ID badge” visible from 50 meters away.

Zone Control

In high-risk zones like a 132kV Substation or a Chemical Storage Area, access is restricted to competent personnel only.

- If I see a Yellow Hat (General Labor) wandering inside a High-Voltage Substation, I know instantly that a boundary has been breached. I don’t need to ask them what they are doing; I know they shouldn’t be there.

- If I see a Grey Hat (Visitor) standing near an open trench without a White Hat (Supervisor) next to them, I know our escort policy has failed.

Behavioral Enforcement

When workers know their role is visible, they are less likely to drift into areas where they don’t belong. It creates a self-policing culture where a Supervisor (White) will instinctively intercept a Laborer (Yellow) entering a technical zone.

3. Helmet Integrity & The “Sticker” Problem

The “Pro Tip” regarding stickers is often ignored, but it is a major compliance issue during my audits.

The Danger of “Helmet Graffiti” Workers love to personalize their gear with sports team logos, funny slogans, or political stickers.

- Hidden Cracks: Hard hats are designed to crack upon impact to absorb energy. If a helmet is covered in random stickers, I cannot inspect the shell for hairline fractures or UV degradation during a quarterly inspection.

- Chemical Reaction: The glue on unauthorized consumer stickers can sometimes react with the HDPE (High-Density Polyethylene) shell, weakening the plastic over time.

The Standardization Rule: I enforce a “Competency Only” sticker policy. The only stickers allowed on a hard hat should be:

- Site Induction Number: Proves they are legally allowed on site.

- Qualification: “First Aid,” “Banksman,” “Fire Warden,” or “Electrician.”

- Medical Alerts: “Diabetic” or “Epileptic” (crucial for paramedics).

Why This Matters: If I see a Blue Hat (Electrician) with a “High Voltage Authorized” sticker, I know I can trust them with a permit. If I see a Blue Hat without that sticker, they are just a wire-puller, not an authorized person. The hat gives the role; the sticker proves the competency.

Standardization is about removing ambiguity. On a loud, dusty, dangerous job site, ambiguity kills. By strictly enforcing these color codes and sticker policies, we turn a sea of anonymous workers into a structured, visible, and manageable command system.

Conclusion

A hard hat is more than just impact protection; it is an identifier of role, competency, and authority. While OSHA may not fine you for having a chaotic color system, the operational cost of confusion is high. In an industry where seconds count during an emergency and competency determines survival, strict adherence to these 8 color codes ensures that everyone knows their place, their role, and who to look to when things go wrong.