Excavation work is a critical part of many construction projects, but it also comes with a number of hazards that must be carefully managed. Workers face various risks, from cave-ins and fall to struck-by and electrical hazards when working in trenches or other excavated areas. To ensure the safety of workers on excavation sites, it’s essential to identify potential hazards and implement effective control measures.

This blog post will explore 10 common excavation hazards and discuss the best control practices. Whether you’re a contractor, safety professional, or worker on an excavation site, this guide will provide valuable insights to help keep everyone safe and avoid accidents.

Why Is Excavation And Trench Safety Important?

Excavation and trenching are essential activities in many construction projects. However, they are also some of the most hazardous operations in the construction industry, and safety must be a top priority during their execution. There are various risks associated with excavation and trenching activities, including the collapse of soil walls, falling loads, hazardous atmospheres, and accidents involving heavy equipment. These hazards can cause serious injury, disability, or even death.

To mitigate these risks, regular pre-work inspections must be conducted to identify potential hazards and take necessary precautions. During the inspection, the type of excavation being conducted should be evaluated, as different types of excavation require different safety measures. The support and warning systems in place should also be checked to ensure they are adequate for the type of excavation being carried out.

Access areas should be identified and properly marked to prevent unauthorized entry and ensure the safety of workers and bystanders. The inspection should also consider weather conditions, as wet or unstable soil can increase the risk of cave-ins. Heavy equipment should be checked to ensure they are in proper working condition, and workers should wear appropriate personal protective equipment (PPE) such as hard hats, gloves, and safety boots.

Difference Between Trenching and Excavation

Excavation is a term used to describe any man-made cut in the earth’s surface. It is a broad term that includes various types of excavations, and one of them is a trench. A trench is a type of excavation that is typically longer than it is wide and is generally deeper than it is wide. Although a trench can be referred to as a trench excavation, it is important to note that not all excavations are trenches.

In simpler terms, excavation is the general term that encompasses all types of earthworks, including trenches. A trench is a specific type of excavation that is narrow in relation to its length and is deeper than it is wide.

Excavations Hazards and Control Measures

Excavation work can be dangerous if proper precautions are not taken. Here are some common excavation hazards and control measures to prevent accidents and injuries:

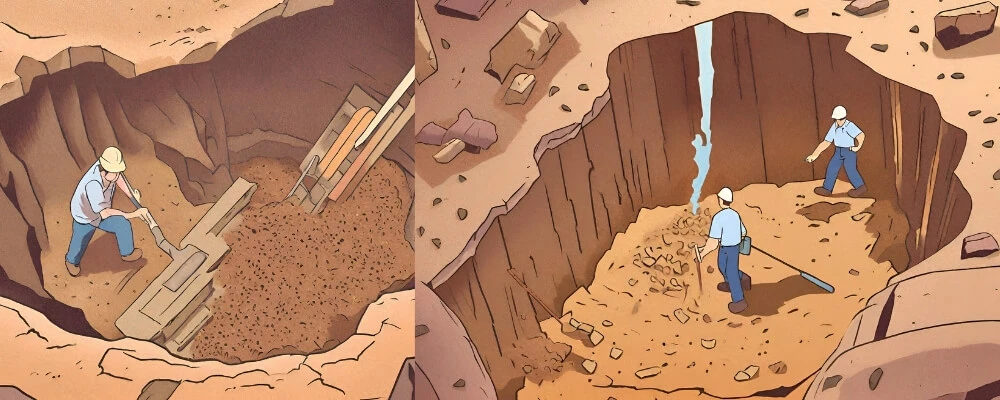

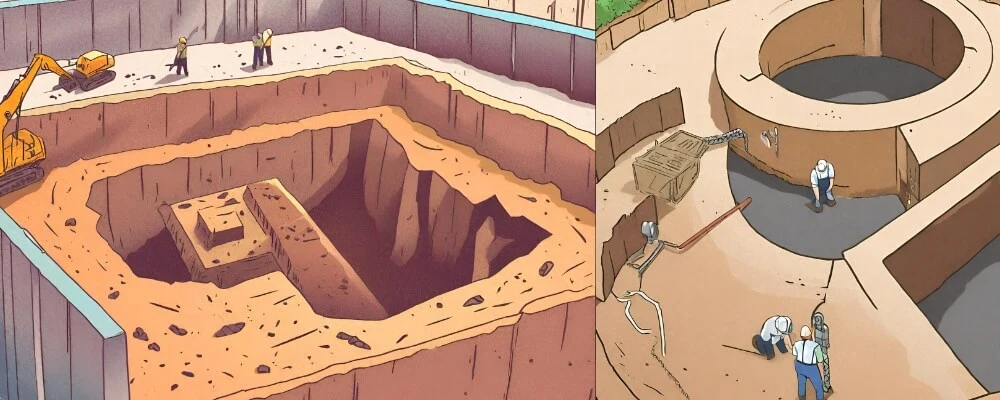

1. Cave-ins and collapses

Soil instability can lead to cave-ins, posing significant risks to workers in and around excavations. When soil loses its structural integrity, it can collapse into the excavation, trapping or crushing workers beneath the weight of the earth. Various factors contribute to soil instability, including:

- Soil type: Different types of soil have varying levels of stability. For instance, cohesive soils like clay are generally more stable than granular soils like sand or gravel. However, even cohesive soils can become unstable under certain conditions, such as prolonged exposure to water.

- Excavation depth: The deeper the excavation, the greater the pressure the surrounding soil exerts. This increased pressure can cause the soil to become unstable and lead to cave-ins.

- Weather conditions: Rain, snow, and other forms of precipitation can cause soil to become saturated, reducing its structural integrity. Also, freezing and thawing cycles can create soil movement, increasing cave-ins risk.

- Nearby construction activities: Vibrations from heavy machinery or construction activities can cause soil to lose stability, potentially resulting in a cave-in.

- Improper excavation techniques: Failing to adhere to proper excavation practices, such as sloping, benching, or shoring, can lead to soil instability and increase the likelihood of a cave-in.

To mitigate the risk of cave-ins and collapses, it is essential to implement appropriate protective measures, such as:

- Conducting a thorough pre-excavation assessment to determine the soil type and stability, identify potential hazards, and select the most suitable protective systems.

- Implementing protective systems, including sloping (angling the excavation walls away from the excavation), benching (creating steps in the excavation walls), or shoring (using support structures to prevent soil movement).

- Regularly inspecting excavation sites to identify and address any signs of soil instability or other hazards.

- Monitoring weather conditions and adjusting work practices to maintain a safe work environment.

- Providing workers with comprehensive safety training, including proper excavation techniques, hazard recognition, and safe work practices.

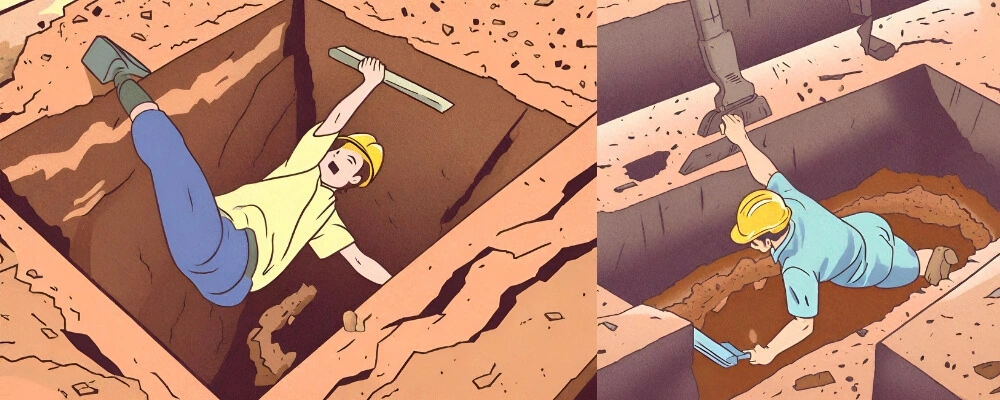

2. Falls

Falls can occur when workers are working near the excavation’s edge or climbing in or out of the excavation. To minimize the risk of falls and ensure a safe work environment, the following control measures should be implemented:

- Providing proper fall protection: Install guardrails, safety nets, or fall arrest systems around the excavation edges to prevent workers from accidentally falling in.

- Using appropriate ladders: Ensure that ladders extend at least three feet above the excavation edge to provide a secure handhold. Ladders should also be secured, well-maintained, and inspected regularly for damage or defects.

- Providing a safe means of egress: In addition to ladders, ramps, stairs, or other safe exit points should be available for workers to exit the excavation easily.

- Placing barriers around the excavation: Barriers, such as fencing or barricades, can mark the excavation perimeter, ensuring everyone on the site knows its location.

- Using bright-coloured or reflective tape: Apply brightly coloured or reflective tape around the excavation edge to increase visibility, especially in low-light conditions.

- Proper signage: Post clear and visible signs around the excavation to indicate its location and any potential hazards. Signs should be easily readable and maintained throughout the project.

- Implementing a fall protection plan: Develop a site-specific fall protection plan that outlines the procedures, equipment, and training necessary to prevent falls. This plan should be communicated to all workers and updated as needed.

- Fall protection training: Provide workers with comprehensive fall protection training, including hazard identification, proper use of equipment, and safe work practices.

By implementing these control measures, the risk of falls can be significantly reduced, ensuring workers’ safety and the excavation project’s overall success.

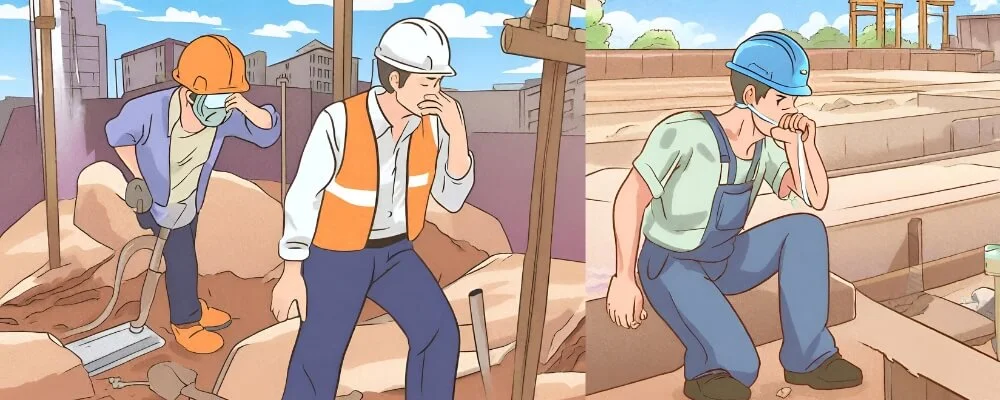

3. Inhalation Hazards

Excavations can expose workers to hazardous atmospheres, which can cause severe health problems or even death. One of the most significant inhalation hazards is carbon monoxide (CO), a colourless, odourless gas produced when fuels such as gasoline, propane, or natural gas are burned. CO is particularly dangerous because it bonds with the haemoglobin in red blood cells, reducing the amount of oxygen carried throughout the body.

To mitigate the risk of inhalation hazards, the following control measures should be implemented:

- Adequate ventilation: Ensure adequate ventilation is in place to remove any hazardous gases, fumes, or vapours from the excavation.

- Testing the atmosphere: Regularly test the atmosphere in the excavation to detect any hazardous gases and determine if corrective measures are necessary.

- Proper equipment use: Use appropriate equipment for the job and maintain it correctly to minimize the risk of hazardous gas exposure.

- Personal protective equipment: Provide workers with appropriate personal protective equipment (PPE), such as respiratory protection or gas detectors, to minimize the risk of inhalation hazards.

- Proper work practices: Train workers on proper work practices to minimize the risk of hazardous gas exposure, such as using exhaust systems for gas-powered equipment or avoiding smoking near the excavation.

- Monitoring: Continuously monitor the atmosphere in and around the excavation to detect any changes that may indicate the presence of hazardous gases.

By implementing these control measures, the risk of inhalation hazards can be minimized, ensuring a safe work environment for all workers involved in the excavation project.

4. Lack Of Oxygen

Excavations can create an oxygen-deficient environment, which can cause dizziness, confusion, unconsciousness, and even death. Oxygen deficiency occurs when the oxygen concentration in the air falls below 19.5%. Some key factors that increase the risk of oxygen deficiency in excavations include:

- Displacement of oxygen: Different gases and compounds in the trench and surrounding area can displace oxygen, reducing its concentration below safe levels.

- Absorption of oxygen: Oxygen can be absorbed by chemical processes in the trench or by rust, which is metal oxidisation.

To mitigate the risk of oxygen deficiency, the following control measures should be implemented:

- Proper ventilation: Ensure adequate ventilation is in place to maintain a safe oxygen level in the excavation.

- Regular atmosphere testing: Conduct regular atmosphere testing to detect changes in oxygen concentration and implement appropriate corrective measures.

- Proper work practices: Train workers on proper work practices to minimize the risk of oxygen deficiency, such as avoiding combustion or flame-producing activities in the excavation.

- Use of personal protective equipment: Provide workers appropriate respiratory protection to prevent oxygen deficiency in an oxygen-deficient atmosphere.

- Emergency preparedness and response: Develop and communicate an emergency action plan that includes procedures for responding to an oxygen-deficient atmosphere, such as providing emergency oxygen and evacuating workers from the excavation.

By implementing these control measures, the risk of oxygen deficiency can be minimized, ensuring a safe work environment for all workers involved in the excavation project.

5. Underground Utilities

Excavation activities can accidentally strike or damage underground utilities, such as water, electrical, and natural gas lines, causing severe injuries, fatalities, and property damage. Some key factors that increase the risk of utility strikes in excavations include:

- Inaccurate utility locating: Failure to accurately locate and mark underground utilities before excavation begins can result in accidental damage or disruption.

- Inadequate support: Excavating near underground utilities without adequate support can lead to collapse, damage, or disruption of the utilities.

To mitigate the risk of utility strikes, the following control measures should be implemented:

- Pre-excavation planning: Conduct a thorough pre-excavation assessment to determine the location of underground utilities and establish appropriate protective measures.

- Utility locating: Use utility locating services to identify and mark underground utilities before excavation begins.

- Proper excavation techniques: Adhere to proper excavation techniques, such as sloping, benching, or shoring, to minimize the risk of utility strikes.

- Protective equipment: Use appropriate protective equipment, such as trench boxes or shields, to protect underground utilities during excavation.

- Safe work practices: Train workers on safe work practices to minimize the risk of utility strikes, such as avoiding using heavy machinery near underground utilities or not working in areas where underground utilities are located.

- Emergency preparedness and response: Develop and communicate an emergency action plan that includes procedures for responding to utility strikes, such as contacting utility providers and evacuating workers from the excavation.

By implementing these control measures, the risk of utility strikes can be minimized, ensuring the safety of workers and the successful completion of the excavation project.

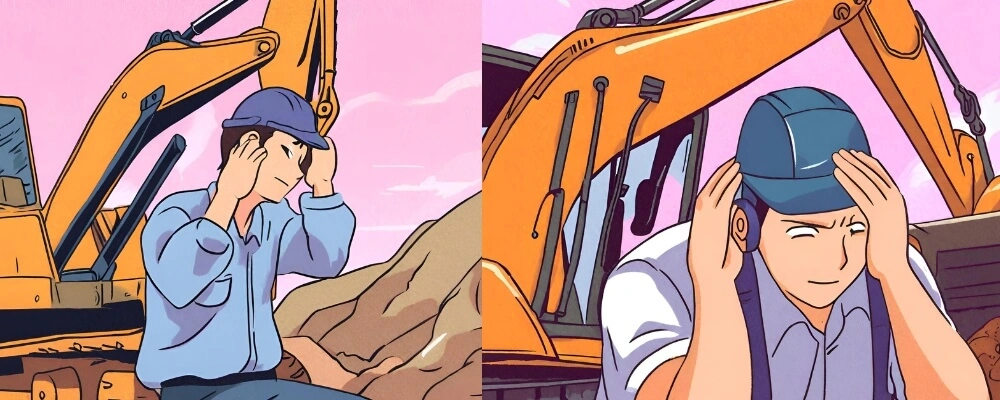

6. Vibration And Noise Hazards

Excavations involve the use of heavy machinery and equipment, which can create vibration and noise hazards for workers. Prolonged exposure to these hazards can cause hearing loss, tinnitus, and other health issues. Some key factors that increase the risk of vibration and noise hazards in excavations include:

- Use of heavy machinery: Heavy machinery used in excavations, such as backhoes, bulldozers, and excavators, can generate significant vibrations and noise levels.

- Exposure time: Workers exposed to prolonged vibrations and noise are at higher risk of developing health issues.

To mitigate the risk of vibration and noise hazards, the following control measures should be implemented:

- Use of appropriate equipment: Use equipment that generates lower vibration and noise levels, where possible.

- Maintenance and inspection of equipment: Ensure that equipment is well-maintained and inspected regularly to minimize the risk of excessive vibration and noise.

- Personal protective equipment: Provide workers with appropriate personal protective equipment, such as earplugs or earmuffs, to minimize the risk of hearing loss and other health issues.

- Proper work practices: Train workers on proper work practices to minimize the risk of vibration and noise hazards, such as reducing the duration of exposure, maintaining a safe distance from operating machinery, and taking regular breaks.

- Regular monitoring: Monitor vibration and noise levels to identify potential hazards and implement appropriate corrective measures.

By implementing these control measures, the risk of vibration and noise hazards can be minimized, ensuring a safe work environment for all workers involved in the excavation project.

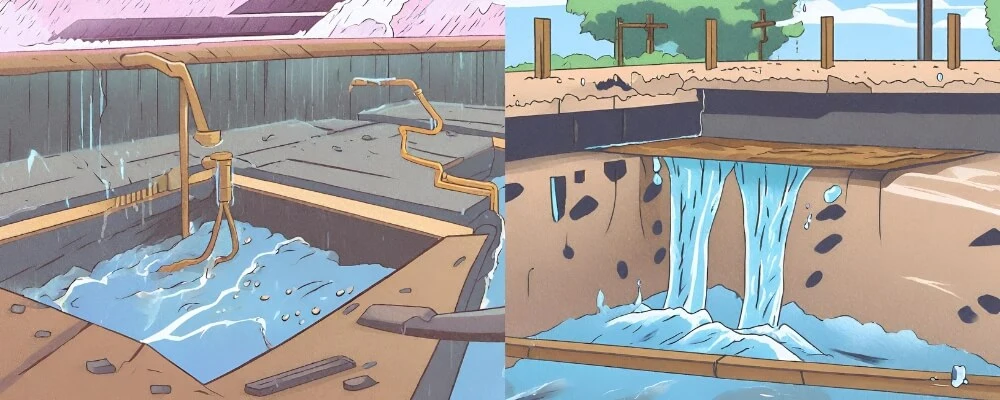

7. Water Ingress And Flooding

Excavations risk filling with water due to heavy rainfall, broken water lines, or other factors, creating drowning or electrocution hazards for workers. Some key factors that increase the risk of water ingress and flooding in excavations include:

- Proximity to water sources: Excavations near bodies of water, such as rivers or lakes, are at higher risk of flooding.

- Heavy rainfall: Prolonged periods can cause excavations to fill with water quickly.

- Broken water lines: Excavations can strike or damage water lines, causing water to enter the excavation.

To mitigate the risk of water ingress and flooding, the following control measures should be implemented:

- Pre-excavation planning: Conduct a thorough pre-excavation assessment to determine the risk of water ingress and establish appropriate protective measures.

- Adequate drainage: Ensure adequate drainage is in place to remove water from the excavation.

- Proper excavation techniques: Adhere to proper excavation techniques, such as sloping, benching, or shoring, to minimize the risk of water ingress and flooding.

- Emergency preparedness and response: Develop and communicate an emergency action plan that includes procedures for responding to water ingress and flooding, such as evacuation and contacting emergency services.

- Safe work practices: Train workers on safe work practices to minimize the risk of water ingress and flooding, such as avoiding working in excavations during periods of heavy rainfall.

By implementing these control measures, the risk of water ingress and flooding can be minimized, ensuring the safety of workers and the successful completion of the excavation project.

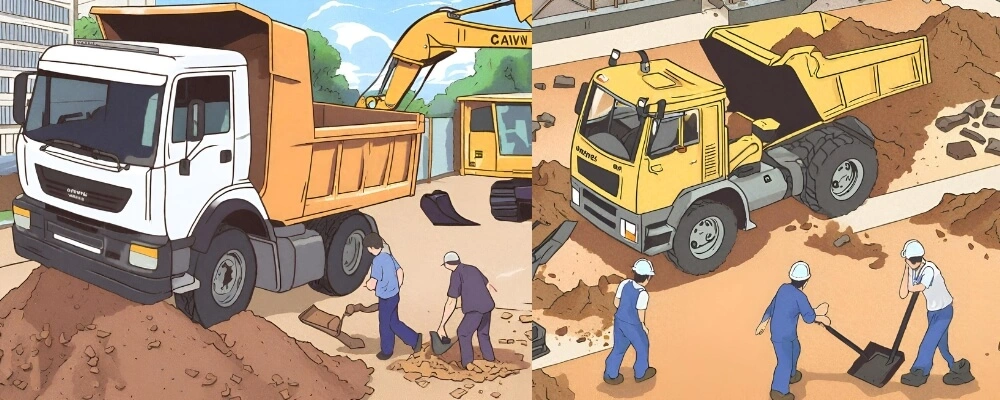

8. Mobile Equipment Accidents

Excavations often involve the use of mobile equipment, such as dump trucks, backhoes, and excavators, which can pose a significant risk of accidents for workers. One of the most significant hazards is workers being struck or run over by mobile equipment operating in the vicinity of the excavation. Some key factors that increase the risk of mobile equipment accidents in excavations include:

- Proximity to mobile equipment: Workers working close to mobile equipment are at higher risk of being struck or run over.

- Visibility: Poor visibility due to weather conditions, darkness, or obstructed views can increase the risk of accidents.

To mitigate the risk of mobile equipment accidents, the following control measures should be implemented:

- Establishing traffic control: Develop a safe procedure for moving mobile equipment around the excavation site.

- Marking out the excavation: Clearly mark out the perimeter of the excavation to indicate to equipment operators where the excavation is located.

- Proper equipment operation: Ensure that mobile equipment operators are appropriately trained and follow safe operating procedures, such as checking blind spots and using spotters.

- Safety equipment: Provide workers with appropriate personal protective equipment, such as high-visibility clothing or hard hats, to increase visibility and minimize the risk of accidents.

- Safe work practices: Train workers on safe work practices to minimize the risk of mobile equipment accidents, such as avoiding working close to mobile equipment and maintaining a safe distance from operating machinery.

- Regular monitoring: Monitor mobile equipment operations to identify potential hazards and implement appropriate corrective measures.

Implementing these control measures can minimise the risk of mobile equipment accidents, ensuring a safe work environment for all workers involved in the excavation project.

9. Confined Spaces

Excavations can create confined spaces, which pose significant risks for workers. A confined space is an enclosed or partially enclosed area with limited means of entry or exit and is not designed for continuous occupancy. Confined spaces in excavations can create risks such as hazardous atmospheres, entrapment, or engulfment. Some key factors that increase the risk of confined space hazards in excavations include:

- Size of the excavation: Small or narrow Excavations can create confined spaces.

- Lack of ventilation: Poor ventilation can create hazardous atmospheres, such as low oxygen levels, which can pose a significant risk to workers.

- Presence of hazardous materials: Excavations can contain hazardous materials, such as gas, chemicals, or fumes, creating a hazardous atmosphere in a confined space.

To mitigate the risk of confined space hazards, the following control measures should be implemented:

- Pre-excavation assessment: Conduct a thorough pre-excavation assessment to determine the risk of confined space hazards and establish appropriate protective measures.

- Confined space entry procedures: Establish procedures for entering confined spaces in excavations, including requirements for testing the atmosphere, using proper personal protective equipment, and having an attendant on standby.

- Proper ventilation: Ensure adequate ventilation is in place to remove hazardous gases, fumes, or vapours from the confined space.

- Emergency preparedness and response: Develop and communicate an emergency action plan that includes procedures for responding to confined space incidents, such as rescue and evacuation.

- Safe work practices: Train workers on safe work practices to minimize the risk of confined space hazards, such as avoiding entry into confined spaces unless necessary and ensuring that proper procedures are followed when entering a confined space.

By implementing these control measures, the risk of confined space hazards can be minimized, ensuring workers’ safety and the excavation project’s successful completion.

10. Temperature Extremes

Excavations can expose workers to extreme temperatures, both hot and cold, leading to heat or cold stress. These conditions can cause severe health problems, tissue damage, and even death. Some key factors that increase the risk of temperature extremes in excavations include:

- Exposure time: Workers exposed to extreme temperatures for prolonged periods are at higher risk of developing health issues.

- Environmental conditions: Hot and cold temperatures can vary depending on the environmental conditions, such as humidity, wind, or sunlight.

To mitigate the risk of temperature extremes, the following control measures should be implemented:

- Adequate protection: Provide workers with appropriate protective equipment, such as insulated clothing or cooling vests, to minimize the heat or cold stress risk.

- Safe work practices: Train workers on safe work practices to minimize the risk of temperature extremes, such as taking regular breaks in a shaded or temperature-controlled area.

- Monitoring: Monitor workers’ physical and environmental conditions to identify potential hazards and implement appropriate corrective measures.

- Proper hydration: Encourage workers to drink plenty of fluids to prevent dehydration in hot conditions and avoid drinking cold fluids in cold conditions.

- Emergency preparedness and response: Develop and communicate an emergency action plan that includes procedures for responding to extreme temperature incidents, such as providing first aid or evacuating workers from the excavation.

By implementing these control measures, the risk of temperature extremes can be minimized, ensuring a safe work environment for all workers involved in the excavation project.

Additional Excavation Hazards To Consider

In addition to the ten common excavation hazards and control measures discussed in this article, several other hazards should also be considered when planning and conducting excavation work. These hazards include:

- Biological hazards: Excavations may expose workers to biological hazards, such as insects, animals, or contaminated soil. Workers should be trained on proper hygiene practices and provided with appropriate personal protective equipment, such as gloves or masks.

- Chemical hazards: Excavations may expose workers to hazardous chemicals, such as solvents, fuels, or pesticides. Workers should be trained on proper handling, storage, and disposal of hazardous chemicals and provided with appropriate personal protective equipment, such as respirators or chemical-resistant clothing.

- Fire hazards: Excavations may create a fire hazard, especially when working near flammable materials or gases. Workers should be trained on proper fire prevention and response procedures, and fire extinguishers should be readily available.

- Structural hazards: Excavations may expose workers to structural hazards, such as unstable walls or collapsed structures. Workers should be trained on proper shoring and bracing techniques, and the excavation site should be inspected regularly to identify potential hazards.

- Machinery hazards: Excavations involve the use of heavy machinery, which can pose a risk of machinery-related accidents. Workers should be trained on the proper use and maintenance of machinery, and appropriate protective equipment, such as hard hats or safety glasses, should be provided.

By considering these additional hazards and implementing appropriate control measures, excavation work can be conducted safely and efficiently, protecting the health and well-being of workers and the success of the excavation project.

Conclusion

Excavation work involves many hazards that can lead to serious injuries or fatalities if not appropriately addressed. However, with proper planning and control measures, many of these hazards can be minimized or eliminated. In this article, we have discussed ten common excavation hazards, including falls, cave-ins, inhalation hazards, lack of oxygen, underground utilities, vibration and noise, water ingress and flooding, mobile equipment accidents, confined spaces, and temperature extremes.

We have also provided control measures that can be implemented to minimize these hazards, including pre-excavation planning, proper work practices, regular monitoring, personal protective equipment, and emergency preparedness and response. By implementing these measures, workers can be better protected, and excavation projects can be completed safely and successfully. It is essential to prioritize safety in excavation work, and these control measures provide a foundation for creating a safe work environment for all involved.