As a Lead Auditor and Occupational Safety Expert with over a decade in high-risk heavy industries, I was recently inspecting an aging fertilizer plant where a maintenance technician had slipped inside a 50-foot caged ladder. Suspended by his tool belt, which had wedged between the rungs and a corroded horizontal hoop, he was trapped 40 feet above the concrete deck, effectively wedged into a steel chute. The very equipment designed decades ago to “protect” him had instead created an entrapment hazard that required a complex, hour-long high-angle rescue. This incident perfectly captures the dangerous contradiction of legacy fall protection: the illusion of safety can be far more hazardous than no safety at all.

For generations, ladder cages were the unquestioned standard in industrial climbing, but the reality on the ground has forced a massive regulatory and cultural shift. In this article, I will walk you through exactly what a ladder cage is, why the global safety community is phasing them out, and how to critically evaluate your current systems. We will break down safe usage protocols for existing cages, the hard truth about their effectiveness, and the modern alternatives you must adopt to truly protect your workforce.

What is a Ladder Cage?

In the field, we define a ladder cage as a passive, permanent structural enclosure attached to a fixed vertical ladder. Built from a framework of continuous vertical steel bars and horizontal hoop bands, it encircles the climbing zone of the ladder.

Historically mandated on fixed ladders exceeding 20 feet, the cage is engineered to create a physical boundary around the climber. Its sole geometric purpose is to prevent a worker from inadvertently falling backward or sideways into the open air while ascending or descending.

Purpose and Functionality of Ladder Cages

The original purpose of a ladder cage was to provide a barrier of containment. Before the advent of modern self-retracting lifelines, safety engineers relied on these metal chutes to keep climbers oriented toward the rungs.

Functionally, a ladder cage works by restricting the available space behind the climber. If a worker loses their footing, the cage is intended to catch them against the back wall, allowing them to theoretically regain their grip.

However, from a physics and biomechanics perspective, the functionality is severely limited. Cages possess zero energy-absorbing properties and no active braking mechanisms, meaning they function more like a guide chute than a safety net.

Benefits of Ladder Cages

While heavily criticized in modern safety engineering, it is important to acknowledge why ladder cages became a standard across power generation and petrochemical complexes.

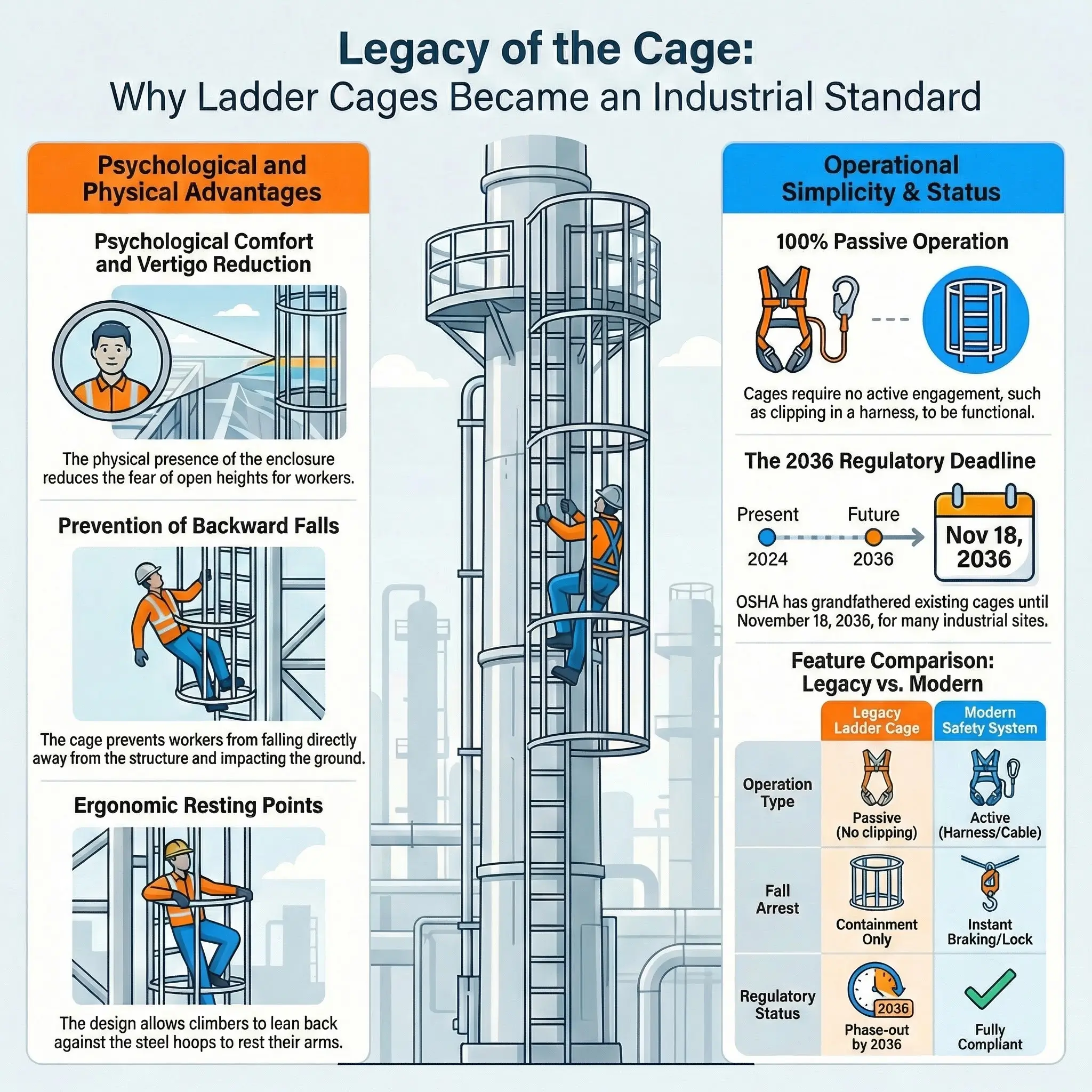

- Psychological Comfort: For workers climbing at extreme heights, the physical presence of a cage reduces vertigo and the fear of open heights.

- Protection from Backwards Falls: They successfully prevent a worker from falling directly away from the ladder and impacting the ground away from the structure.

- Resting Points: The design allows climbers to lean back slightly against the hoops to rest their arms during long climbs, though this is a poor ergonomic practice.

- Passive Operation: Unlike a harness system, a cage requires no active engagement (like clipping in) by the worker to be “functional.”

Tips for Safe Usage of Ladder Cages

Since OSHA has grandfathered in existing cages until 2036, thousands of industrial sites still rely on them daily. If your crew must navigate these legacy structures, strict operational discipline is non-negotiable.

1. Conduct Regular Inspections

Cages are exposed to the same corrosive environments as the structures they serve. I have seen hundreds of cages in chemical plants where internal welds have failed, turning a safety hoop into a sharp impalement hazard. Inspect for corrosion, bolt integrity, and weld strength before every climbing season.

2. Ensure Proper Clearance

Over time, impacts from heavy machinery or structural settling can deform a cage. Ensure the internal clearance maintains a minimum of 27 inches from the centerline of the ladder to the cage wall. Anything less creates an entrapment risk for workers wearing winter gear or harnesses.

3. Provide Worker Training

Climbing a caged ladder requires specific body mechanics. Train your workers to keep their center of gravity close to the rungs and to never carry tools in their hands. Complacency is the biggest killer inside a cage.

4. Supplement with a Fall Arrest System

If you have a high-traffic caged ladder, do not rely on the cage alone. Install a vertical cable system inside the cage (provided clearance allows) so workers can tie off with a cable grab, merging modern protection with the legacy structure.

5. Establish a Rescue Plan

A fallen worker trapped inside a cage is one of the hardest rescues in the industry. Your emergency response team must practice high-angle extractions from within a cage, as standard stretchers often cannot fit inside the 27-inch clearance.

Are Ladder Cages Effective for Fall Protection?

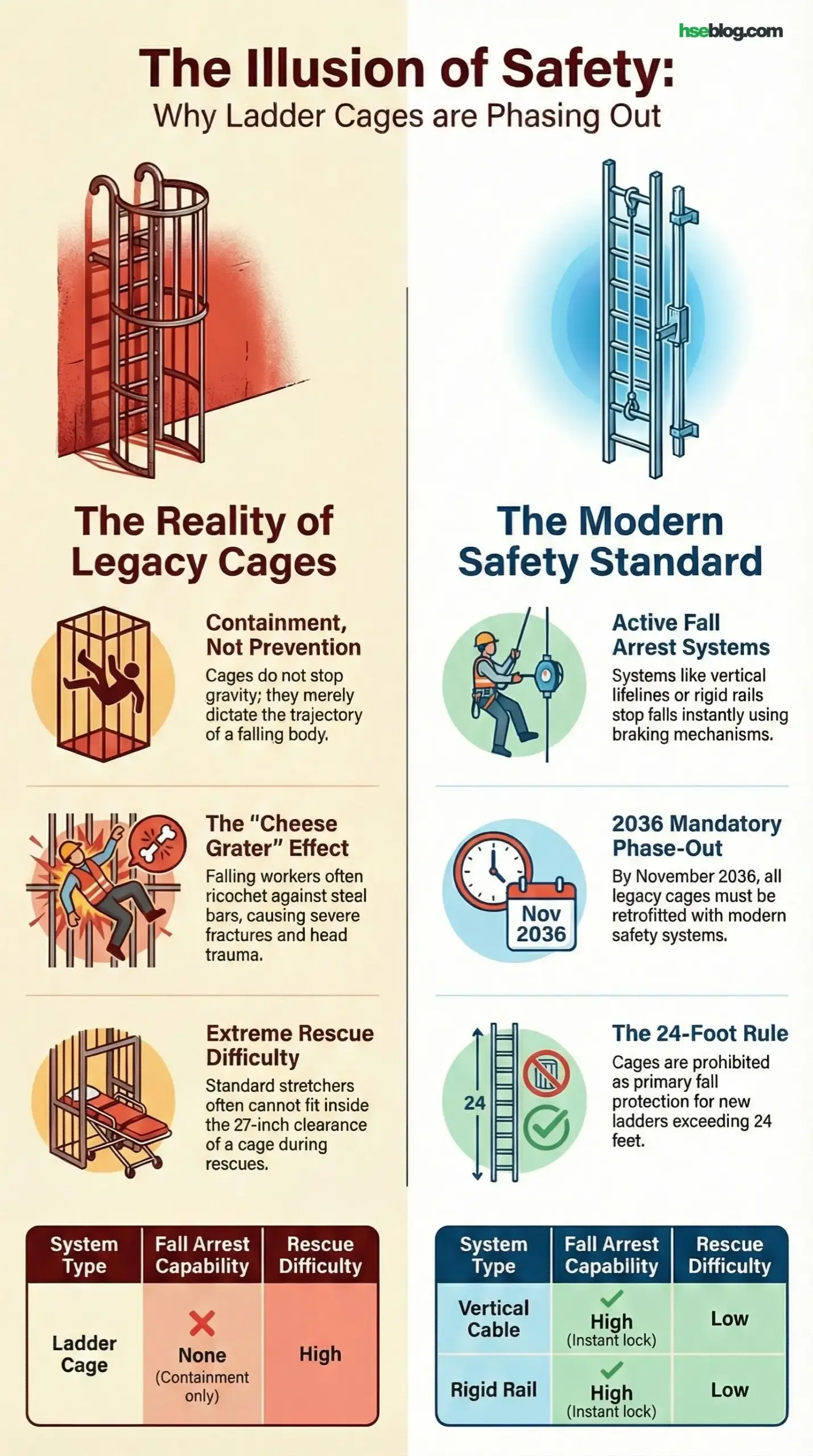

The hard truth, backed by decades of injury data, is that ladder cages are highly ineffective at arresting falls. They do not stop gravity; they merely dictate the trajectory of the falling body.

1. Limited Fall Arrest Capabilities

A ladder cage is a fall containment system, not a fall arrest system. Without an active braking mechanism, a slipping worker will plummet through the cage until they hit an intermediate platform or the ground.

2. Potential for Increased Injury in a Fall

In accident investigations, we refer to the “cheese grater effect.” A falling worker ricochets back and forth against the steel bars at high velocity. This frequently results in complex fractures, severe lacerations, and head trauma that might not have occurred in an open-air fall with proper harness protection.

3. Psychological vs. Practical Safety

Cages provide a false sense of security. Workers often climb faster and with less caution inside a cage because they feel enclosed. This psychological comfort masks the practical reality of the severe hazard.

4. Regulatory Shifts Reflect Limited Effectiveness

Data-driven regulators no longer consider cages sufficient. Modern standards now mandate that fall energy must be absorbed and the fall distance limited to less than two feet, criteria that a traditional steel cage can never meet.

“A safety device that creates new hazards is a liability, not an asset.” — Common consensus among ISO 45001 Lead Auditors.

Alternatives to Ladder Cages for Enhanced Safety

To achieve true fall protection, we must replace passive containment with active arrest. The modern hierarchy of controls offers several superior alternatives that stop falls instantly.

1. Vertical Lifeline Systems

A vertical steel cable runs the length of the ladder. The climber wears a full-body harness connected to a cable grab that travels freely but locks instantly if sudden downward acceleration occurs.

2. Self-Retracting Lifelines (SRLs)

Mounted at the top of the ladder, an overhead SRL feeds a cable down to the worker. It maintains slight tension during the climb and engages a centrifugal brake the moment a slip occurs, limiting the fall to mere inches.

3. Fixed Track Ladder Safety Systems

Similar to cable systems, these utilize a rigid metal rail bolted directly to the center of the ladder rungs. The trolley mechanism provides a smoother climb in high-wind environments and handles environmental corrosion better than flexible cables.

4. Guardrails and Intermediate Platforms

Instead of one massive 60-foot climb, breaking the ladder into shorter, offset sections (under 20 feet) with resting platforms protected by guardrails significantly reduces the maximum possible fall distance.

5. Personal Fall Arrest Systems

Twin-tail lanyards with large rebar hooks allow climbers to maintain 100% tie-off by alternately clipping to the ladder rungs themselves, though this slows down the climb considerably.

Comparison of Fall Protection Systems

| System Type | Fall Arrest Capability | Rescue Difficulty | Regulatory Status (Post-2018) |

| Ladder Cage | None (Containment only) | High | Phasing out (Deadline 2036) |

| Vertical Cable | High (Instant lock) | Low | Fully Compliant |

| Rigid Rail | High (Instant lock) | Low | Fully Compliant |

| Top-Mounted SRL | High (Minimal fall distance) | Moderate | Fully Compliant |

OSHA and Regulatory Standards for Ladder Cages

The regulatory landscape fundamentally changed in 2017 when OSHA updated the Walking-Working Surfaces standard (29 CFR 1910.28). This update aligned U.S. standards with international best practices.

- New Ladders: Cages are strictly prohibited as the sole means of fall protection on any fixed ladder over 24 feet installed on or after November 19, 2018.

- The Grandfather Clause: Existing cages are permitted but must be phased out. By November 18, 2036, all legacy cages must be retrofitted with a modern Ladder Safety System (LSS) or Personal Fall Arrest System (PFAS).

- The Trigger Event: If an existing cage is damaged or requires structural modification before 2036, it loses its grandfathered status and must be upgraded to a modern system immediately.

OSHA 1910.28(b)(9)(i)(D): “On and after November 18, 2036, all fixed ladders (that extend more than 24 feet) must be equipped with a ladder safety system or personal fall arrest system.”

Conclusion

Ladder cages are a relic of an era when safety was based on intuition rather than engineering data. While they provided a psychological safety net for decades, field experience and injury data have proven that they fail to arrest falls and severely complicate emergency rescues. Transitioning to active fall protection systems like rigid rails or self-retracting lifelines is not just a regulatory obligation; it is a critical step in eliminating the trauma associated with caged falls.

As HSE professionals, our ultimate loyalty is to the workers on the rungs, not the budget sheet or the status quo. You cannot put a price on human life, and waiting until the 2036 deadline to protect your workforce is a gamble you cannot afford to take.