When it comes to managing chemical spills, toxic vapor releases, or hazardous material incidents, the margin for error is razor-thin. Personnel involved in these operations are exposed to potentially life-threatening conditions that require precise, informed decisions—none more important than selecting the correct level of personal protective equipment (PPE).

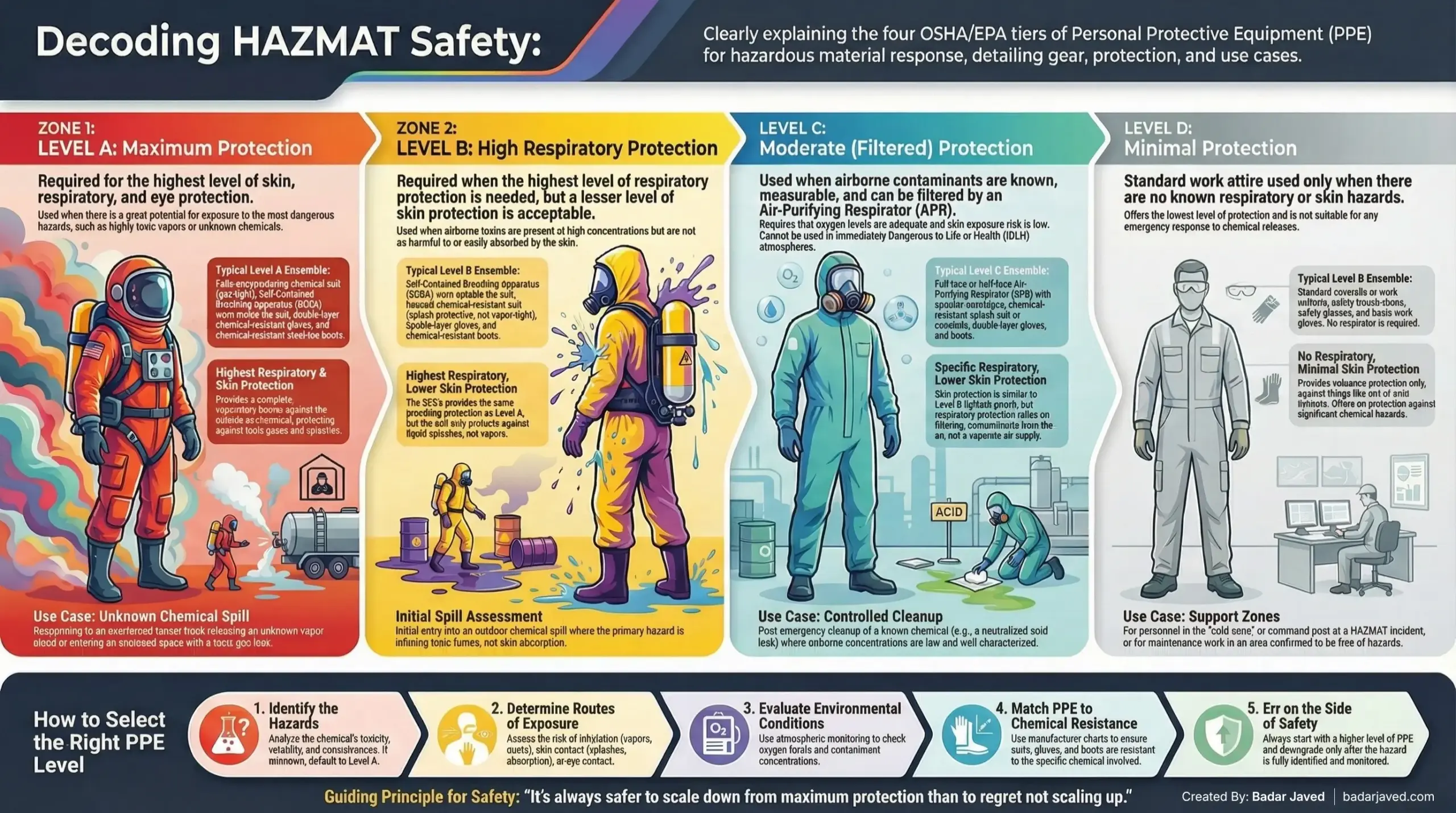

To standardize protection and ensure worker safety, the Occupational Safety and Health Administration (OSHA) and the U.S. Environmental Protection Agency (EPA) have established four PPE levels: Level A, B, C, and D. These levels guide responders and safety officers in choosing the appropriate gear based on the nature and severity of the hazard—whether it’s unknown chemical vapors, low-oxygen environments, or low-risk maintenance zones.

In this comprehensive guide, we’ll explore each PPE level, explain the regulatory criteria behind them, and present real-world use cases that illustrate how these classifications apply during HAZMAT emergencies and industrial operations.

What Are PPE Levels?

PPE Levels refer to standardized categories of Personal Protective Equipment defined by OSHA (Occupational Safety and Health Administration) and the EPA (Environmental Protection Agency). These levels—Level A, B, C, and D—represent graded tiers of protection for personnel responding to hazardous materials incidents or working in environments with potential chemical, biological, or radiological exposure.

Each level specifies a required combination of protective gear based on the severity and type of hazard, including:

- Respiratory protection (e.g., SCBA or air-purifying respirators)

- Skin and eye protection (e.g., chemical suits, gloves, goggles)

- Body coverage (ranging from fully encapsulating suits to standard workwear)

The PPE levels are outlined in OSHA’s HAZWOPER standard (29 CFR 1910.120) and adopted across various emergency response protocols.

Why PPE Levels Matter

The importance of PPE levels cannot be overstated in hazardous environments. Here’s why:

- Life-Saving Protection: Proper PPE levels shield workers from toxic inhalation, chemical burns, skin absorption, and other serious health risks.

- Decision-Making Framework: They give incident commanders and safety officers a clear, structured way to match PPE to the threat level—especially during fast-moving emergencies.

- Regulatory Compliance: Adhering to defined levels ensures compliance with OSHA/EPA mandates, reducing liability and organizational risk.

- Operational Efficiency: Choosing the correct level avoids over-protection (which can lead to fatigue or heat stress) or under-protection (which can lead to injury or fatality).

- Adaptability: The levels support dynamic risk assessment—allowing teams to scale PPE up or down as site conditions change.

PPE levels provide a critical balance between protection, performance, and practicality in high-risk industrial and emergency response settings. Knowing and applying them correctly is a cornerstone of effective HAZMAT safety.

Explaining PPE Levels: A–D

Personal Protective Equipment (PPE) Levels are classifications that define the type and extent of protection required for personnel working in hazardous environments—especially during chemical, biological, or radiological incidents. The four standard PPE levels—A, B, C, and D—are established by the U.S. Environmental Protection Agency (EPA) and incorporated into OSHA’s HAZWOPER regulation (29 CFR 1910.120).

Each level is designed to protect against specific types of hazards by combining respiratory protection and skin protection requirements based on the severity and nature of exposure.

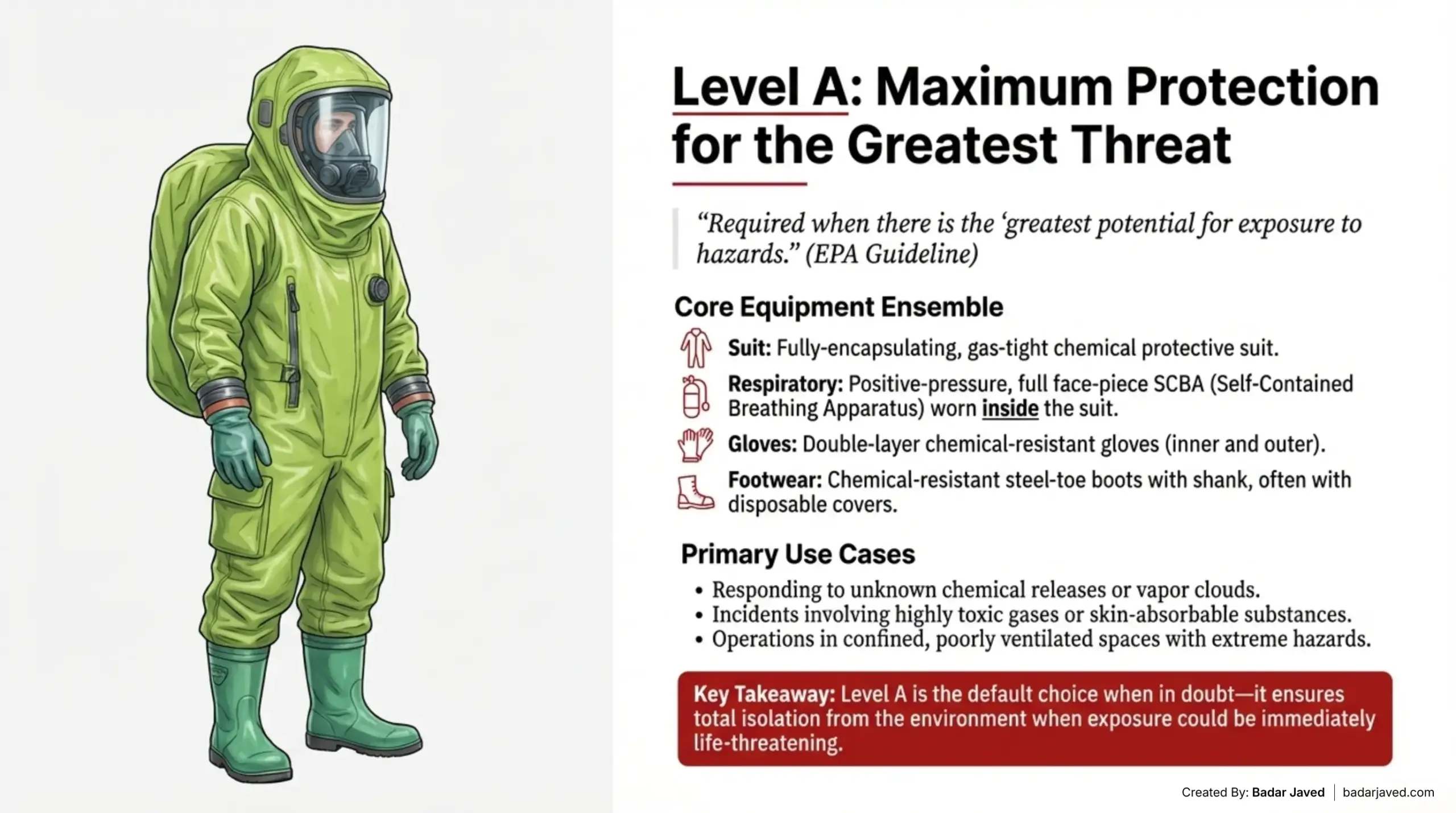

Level A – Highest Protection

Level A provides the greatest level of protection, used when responders face the most dangerous hazards. According to EPA guidelines, Level A is required when there is the “greatest potential for exposure to hazards” and thus the highest level of skin, respiratory, and eye protection is needed.

OSHA likewise specifies selecting Level A when atmospheric vapors or splash risks are high and the substances involved are highly toxic to skin or can be absorbed through the skin. In practical terms, this means any incident with unknown chemicals or extremely hazardous substances (for example, a major toxic gas leak in an enclosed space) would likely warrant Level A protection to fully shield the responder.

Typical Level A PPE Ensemble: Level A gear is characterized by a totally encapsulating suit and self-contained breathing apparatus, forming a gas-tight barrier around the wearer. Examples of Level A equipment include:

- Fully-encapsulating chemical protective suit – gas-tight suit covering the whole body (often called a hazmat suit)

- SCBA (Self-Contained Breathing Apparatus) – a positive-pressure, full face-piece air supply providing breathable air

- Double-layer chemical-resistant gloves – inner and outer gloves to prevent skin contact

- Chemical-resistant boots (steel-toe, with steel shank) – often worn with disposable boot covers for decontamination

Additional items like a hard hat (worn under the suit) and disposable inner suits can be used as needed. The SCBA is worn inside the encapsulating suit, ensuring the user is breathing clean air and completely isolated from the outside atmosphere.

Use Cases

Level A is used in extreme hazard scenarios. For example, HAZMAT teams use Level A suits when working with highly toxic gases or chemicals in confined or poorly ventilated areas, or when there is a high risk of chemical splash or immersion. If a tanker truck carrying unknown chemicals overturns and releases a vapor cloud, responders initially don Level A until they identify the substance and determine a safer level can be used. In essence, Level A is the go-to when in doubt about the hazards – it ensures maximum protection when chemical exposure could be immediately life-threatening or cause severe skin damage.

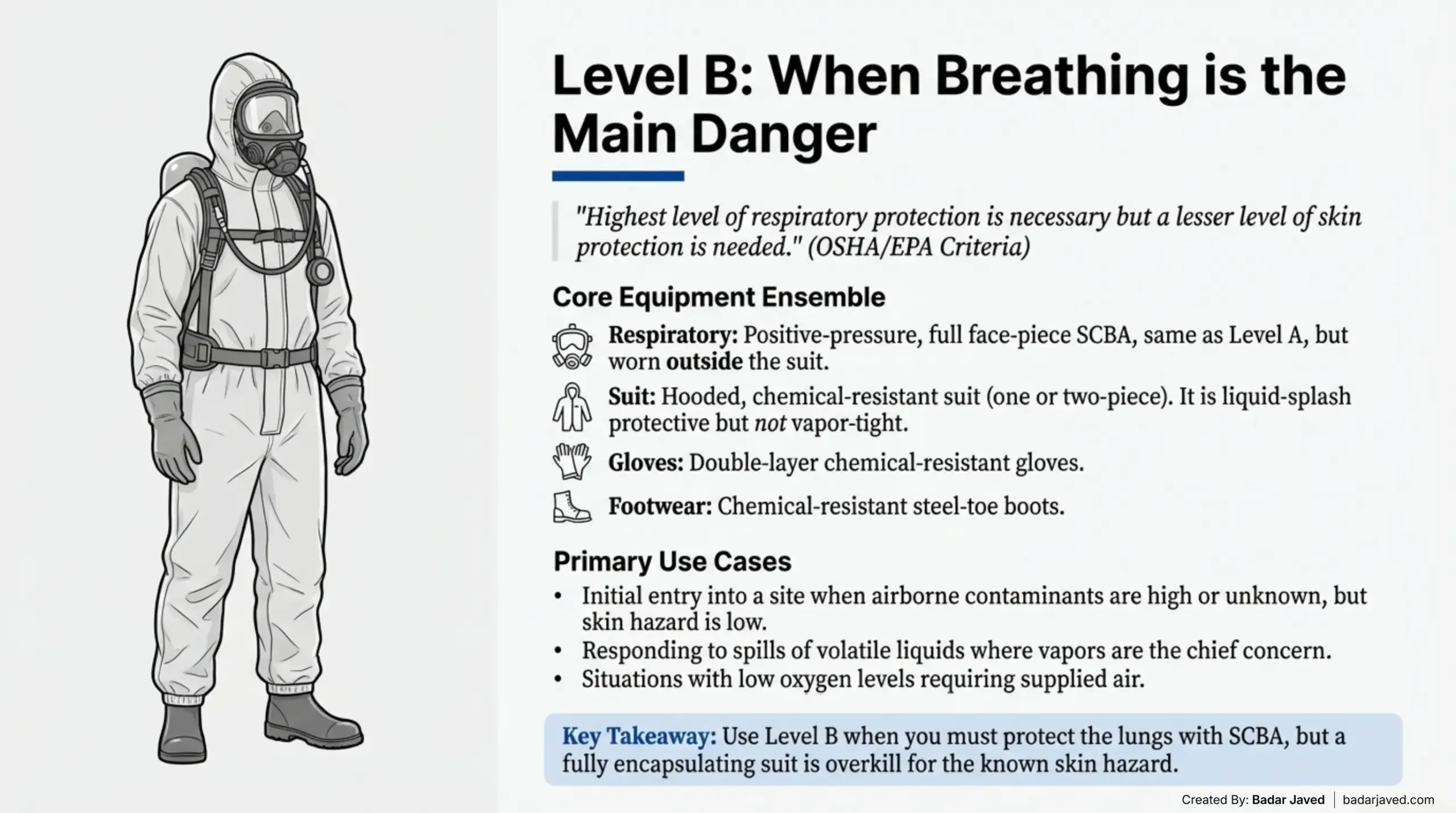

Level B – High Respiratory Protection

Level B PPE is used when the primary danger is from inhaling hazardous substances, requiring the highest level of respiratory protection, but the risk of skin exposure is lower. In OSHA’s criteria, Level B is appropriate when known airborne toxins are present at high concentrations (or oxygen levels are low), yet these substances are not as harmful to the skin. Notably, SCBA is still required in Level B, the same as Level A, but the protective suit provides a lesser degree of skin coverage (non-encapsulating but still chemical-resistant).

This level is common for many emergency responses because fully-encapsulating suits may not be necessary if skin absorption risk is minimal. As the EPA notes, at most outdoor hazardous waste sites, ambient vapor levels typically do not reach those requiring Level A, so Level B protection is often sufficient.

Typical Level B PPE Ensemble: Level B gear offers high respiratory protection with slightly reduced skin coverage compared to Level A. A typical Level B ensemble includes:

- SCBA or supplied-air respirator (positive-pressure, full face-piece) – same high-level respirator as Level A

- Hooded chemical-resistant suit – e.g. a one or two-piece splash suit or coveralls that is not fully vapor-tight

- Chemical-resistant gloves (double layer) – inner and outer gloves to protect hands

- Chemical-resistant boots (steel toe/shank) – typically worn outside the suit, sometimes with additional boot covers

- Face shield and hard hat, as needed – for additional splash protection and impact protection

In Level B, the suit is liquid-splash protective but not vapor-tight. The responder’s SCBA is worn outside the suit (since the suit is not fully encapsulating), and the hooded clothing and gloves protect against splashes or brief contact with chemicals.

Use Cases

Level B is appropriate for situations with significant inhalation hazards but low skin hazard. A common scenario is the initial entry into a chemical spill area when the exact airborne contaminant levels are unknown – responders opt for Level B to ensure SCBA protection in case of toxic fumes or oxygen deficiency. For instance, entering an outdoor spill of a volatile solvent might call for Level B: the responders wear SCBA and splash suits because breathing the vapors is the chief concern, while direct skin contact is less likely or less harmful.

These suits are effective where “breathing is the main danger” and the chemicals present are more dangerous if inhaled than if they contact skin. Level B is also used in cases like checking industrial tanks or areas where chemicals are present in air at dangerous concentrations but are not known to penetrate skin readily. In summary, use Level B when you must protect the lungs and face with SCBA, but a fully encapsulating suit (Level A) would be overkill for the known skin hazard.

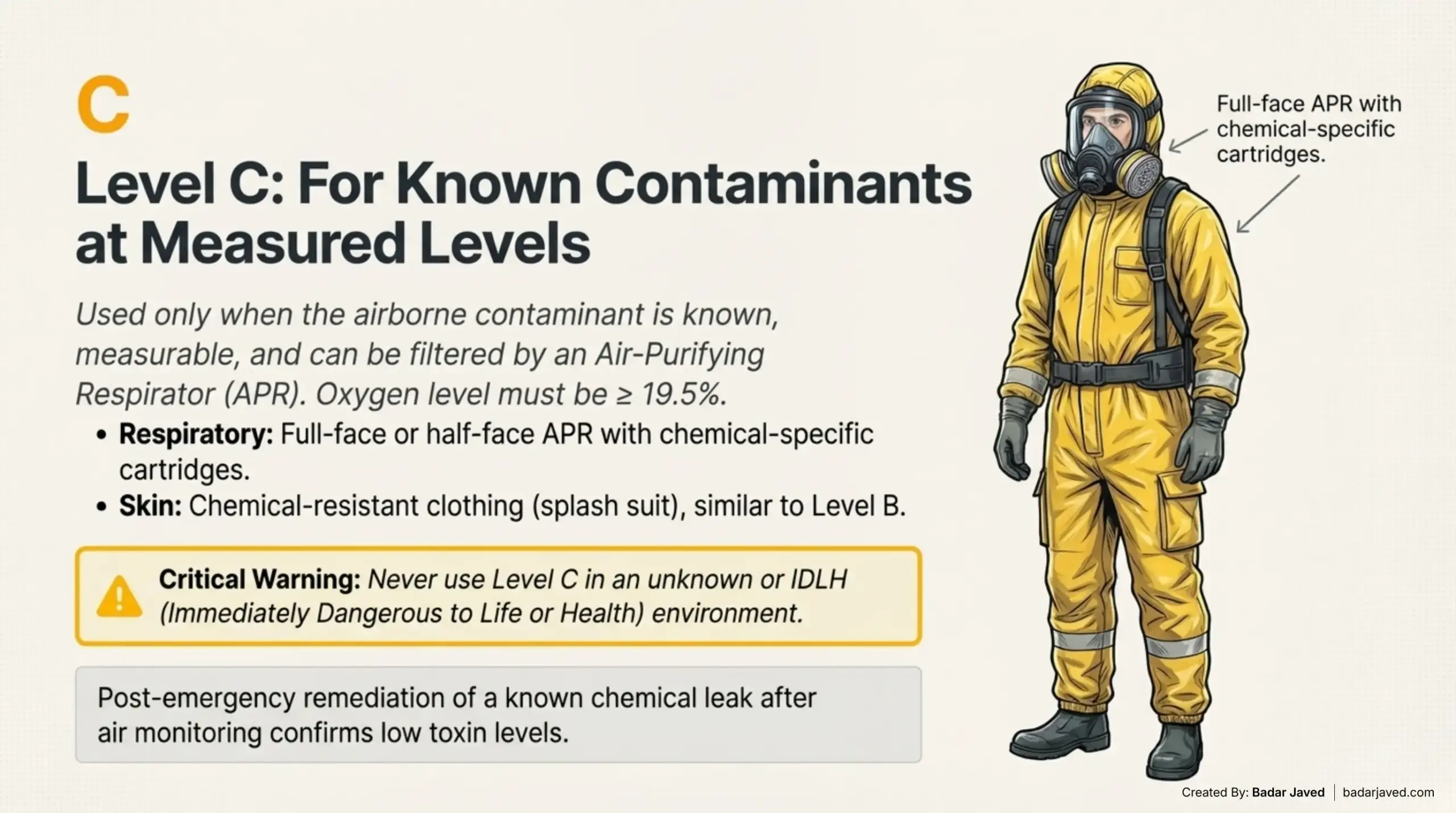

Level C – Moderate Protection (Air-Purifying Respirator)

Level C PPE is utilized when the airborne contaminant is known, measurable, and filterable – meaning air-purifying respirators (APRs) can be safely used – and when skin exposure risk is low. All criteria for using an APR must be met: the oxygen level must be adequate (not IDLH), the specific chemicals are identified, and cartridge filters are available that can remove those chemicals.

Essentially, Level C provides similar skin protection as Level B (splash protection), but instead of an SCBA, a less cumbersome respirator with appropriate cartridges is used for breathing protection. This level is common in controlled work environments or post-emergency cleanup operations where the hazards are understood and under relatively low concentrations.

Typical Level C PPE Ensemble: Level C equipment includes many of the same outer protective garments as Level B, but with an air-purifying respirator in place of an air tank. A typical Level C setup includes:

- Full-face or half-face air-purifying respirator (APR) – NIOSH-approved respirator with cartridges suited to the specific chemicals (often a full-face respirator with organic vapor/P100 cartridges, for example)

- Chemical-resistant clothing – hooded coveralls or two-piece splash suit, providing splash protection for skin

- Chemical-resistant gloves – inner and outer layers, as with higher levels

- Chemical-resistant boots – with steel toe and shank, plus optional boot covers

- Hard hat and/or face shield as needed – e.g. if there is risk of falling objects or chemical splash to the face

The defining element of Level C is the air-purifying respirator. Because the responder is breathing ambient air (filtered through cartridges) rather than bottled air, Level C is only safe if the air contains no highly toxic vapors or oxygen deficiency. The protective clothing in Level C is often the same as or similar to Level B suits (minus being fully encapsulating) – for example, Tyvek® or coated suits that protect against liquid splashes.

Use Cases

Level C is appropriate when hazards are well characterized and at low concentrations. For example, an industrial cleanup crew handling a known chemical spill (such as a small acid leak that has been neutralized) might use Level C: they wear splash protection and filter masks because they know exactly which chemical is present and that an APR can provide sufficient protection. In HAZMAT response, once the air has been monitored and high levels of toxins are no longer present, teams may downgrade from Level B to Level C to continue cleanup efforts more comfortably.

Level C is often used in semi-contaminated areas for decontamination work or handling post-emergency remediation – scenarios where respiratory hazards exist but are at manageable levels. Important: If conditions change (e.g. vapors increase or an unknown hazard is detected), responders must upgrade back to Level B or A. Never use Level C in an unknown environment or one that could be immediately dangerous to life or health (IDLH), as a filter respirator would not provide adequate safety.

Level D – Minimal Protection

Level D is essentially standard work attire with minimal PPE, used in environments with no known respiratory or skin hazards beyond ordinary workplace risks. It offers the lowest level of protection and is only appropriate for “nuisance contamination” situations – that is, areas where one might encounter dirt, dust, or mild irritants but nothing that would cause harm through inhalation or skin contact. Level D has no respiratory protection (no respirator) and only basic skin protection.

OSHA notes that Level D should be used only when the atmosphere contains no hazardous contaminants and there is effectively zero risk of unexpected exposure to dangerous chemicals. This level is not for emergency response to chemical releases, but rather for secondary support or clean areas.

Typical Level D PPE Ensemble: Level D is basically a normal work uniform with a few protective accessories. Components of Level D may include:

- Coveralls or other work clothing – e.g. a chemical-resistant cotton coverall or standard uniform

- Safety boots or shoes (steel-toe if needed) – with chemical-resistant material if necessary

- Gloves – simple work gloves (leather, latex, or nitrile) if needed for minor splash or abrasion protection

- Safety glasses or goggles – eye protection against dust or mild chemicals

- Face shield – optional, for any potential minor splash (e.g. paint or cleaning solution)

- Hard hat – if required by the work area (for head protection rather than chemical protection)

No respirator is used at Level D (other than optional dust masks at most). Essentially, Level D is the PPE one would wear in any safe, controlled work environment: think of mechanics in coveralls, construction workers with hard hats and boots, or lab technicians in lab coats and goggles when no dangerous substances are present.

Use Cases

Level D is only acceptable in situations where there are no significant hazards. In industrial settings, this level is often the starting point for PPE – for example, maintenance staff performing work in a plant area that has already been declared free of chemical hazards would be in Level D (basic coverall, hard hat, gloves).

Examples: A cleanup crew sweeping up non-toxic debris, or workers transporting sealed, non-leaking containers of hazardous waste might use Level D if there’s no chance of exposure. It’s also the attire for support personnel at a HAZMAT incident command post (located in the cold zone) where they are away from any contamination.

As one safety source explains, Level D is “used for ordinary work situations” that involve unpleasant but not dangerous materials, such as general construction or sanitation work. Important: If any possibility of chemical exposure arises (splashes, inhalation, etc.), a higher PPE level is required – Level D will not protect against any significant chemical hazard.

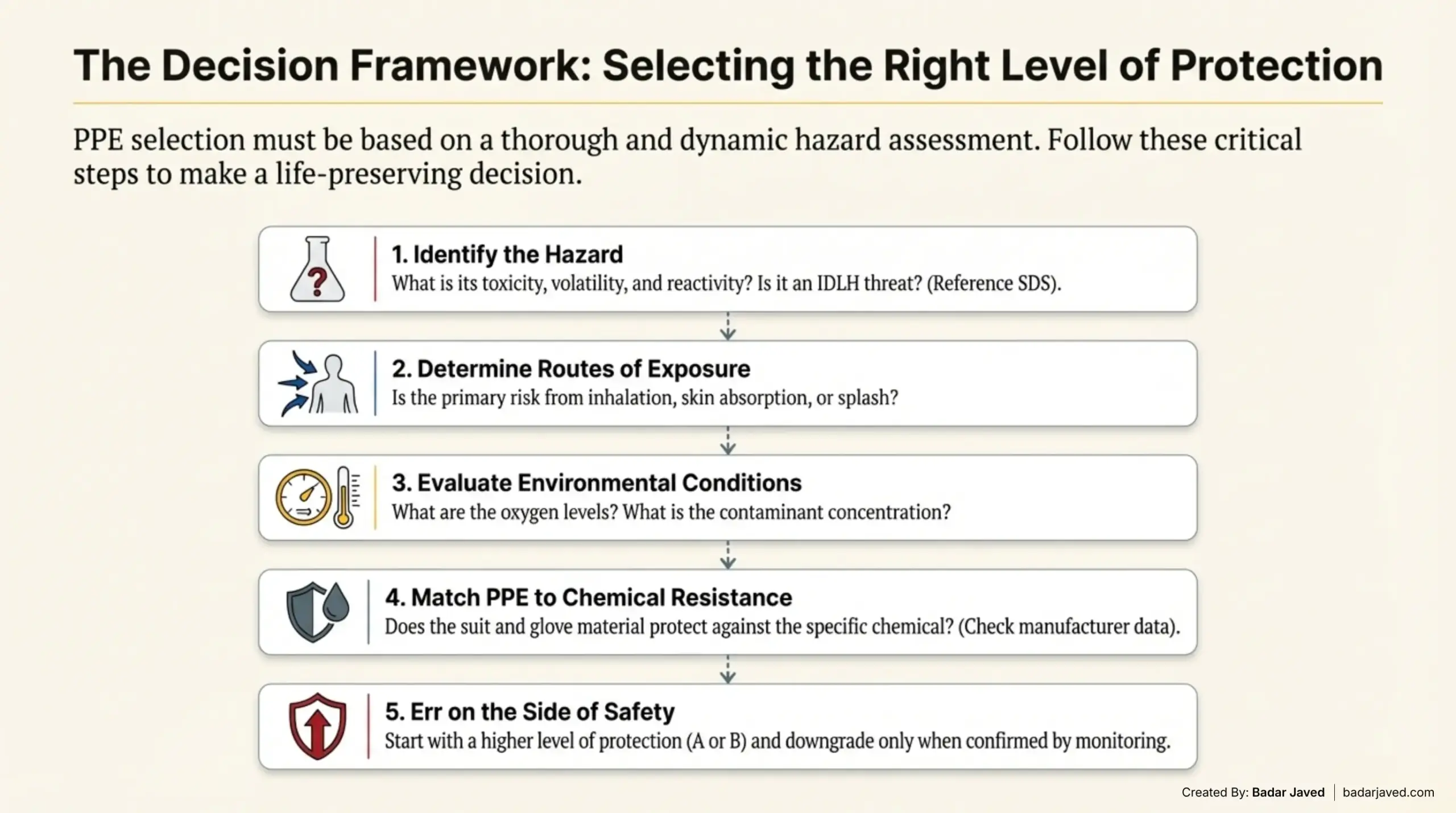

Selecting the Appropriate PPE Level

Choosing the correct PPE level in a chemical or HAZMAT scenario is not just a regulatory step—it’s a life-preserving decision. OSHA emphasizes that PPE selection must be based on a thorough hazard assessment that considers multiple variables:

1. Identify the Hazards

Begin by assessing the physical and chemical characteristics of the substances involved. Review Safety Data Sheets (SDS), chemical inventories, and incident reports. You need to understand:

- The chemical’s toxicity (inhalation, dermal, ingestion)

- Vapor pressure and volatility

- Reactivity and corrosiveness

- Whether the substance poses an IDLH (Immediately Dangerous to Life or Health) threat

If a chemical is unknown or presents multiple unknown risks, default to Level A PPE until further data is available.

2. Determine Routes of Exposure

Understand how a substance can enter the body:

- Inhalation: Risk of airborne vapors, dusts, gases

- Dermal: Skin absorption, splash hazards

- Eye Contact: Irritants or corrosives

- Ingestion: Rare, but possible in contaminated environments

For example, a volatile solvent with strong vapors but limited skin toxicity may justify Level B, while a corrosive acid splash risk with no vapor hazard may only require Level C with skin protection.

3. Evaluate Environmental Conditions

Atmospheric monitoring should confirm:

- Oxygen levels (must be ≥ 19.5% for APR use)

- Presence and concentration of contaminants

- Whether air-purifying respirators (APRs) are adequate, or if SCBA is required

Responders entering an unknown environment must assume worst-case conditions until real-time monitoring confirms otherwise.

4. Match PPE to Chemical Resistance

No single PPE material is universally effective. For example:

- Tyvek® suits resist particulates but not solvents

- Butyl rubber gloves resist ketones but not hydrocarbons

- SCBA tanks provide air, but do not protect against skin exposure

Always match suits, gloves, boots, and respirators to the specific chemical using manufacturer resistance charts and third-party test data.

5. Err on the Side of Safety

When uncertainty exists:

- Start with a higher PPE level (e.g., Level A or B)

- Downgrade after hazard identification and air monitoring

- Upgrade again if site conditions change or new risks emerge

This dynamic approach is built into OSHA’s HAZWOPER model, which allows responders to adapt protection levels in the field.

6. Use Combinations When Necessary

In practice, PPE elements can be mixed to fine-tune protection. For instance:

- A team might wear a splash-resistant suit (Level B clothing) with an APR instead of SCBA, creating a hybrid between Level B and Level C.

- This approach should only be used when the site safety officer confirms it meets all hazard control requirements.

Conclusion

In hazardous materials management, proper PPE selection is not just a regulatory requirement—it’s a mission-critical safeguard that can spell the difference between safe containment and catastrophic exposure. Understanding the four PPE levels—A through D—enables safety professionals to tailor protective measures to the specific risks at hand, ensuring that personnel are neither under-protected nor burdened by unnecessary equipment.

By assessing hazards, monitoring atmospheric conditions, understanding exposure routes, and following OSHA/EPA guidelines, safety officers can make informed decisions that keep teams safe and operations compliant. Whether you’re confronting an unidentified chemical release or managing routine cleanup, always align your PPE choices with the most credible risk.

Remember: in HAZMAT response, it’s always safer to scale down from maximum protection than to regret not scaling up. Equip wisely, train thoroughly, and respond confidently—because lives depend on it.