Safety is paramount in numerous industries, particularly those involving intricate systems, machinery, and processes. Among the various safety metrics and standards, the Safety Integrity Level, commonly called SIL, stands out as a key metric. But what exactly is SIL, and why is it so crucial? This guide aims to shed light on the multifaceted realm of SIL, delving deep into its definitions, implications, challenges, and real-world applications.

From understanding the inherent intricacies of SIL calculations to exploring examples of determining Safety Instrumented Systems (SIS), Safety Instrumented Functions (SIF), and SIL, we’ll journey demystify these pivotal safety benchmarks. Whether you’re a seasoned professional or new to the world of safety standards, this comprehensive overview is designed to equip you with a thorough understanding of SIL and its pivotal role in the safety landscape.

What is a Safety Integrity Level (SIL)?

Safety Integrity Level (SIL) is a measure used in functional safety standards to represent the relative level of risk-reduction provided by a safety instrumented function (SIF). The SIL system categorizes such safety functions’ reliability and performance requirements, with higher SILs indicating greater safety and a lower likelihood of dangerous failures. Based on the IEC 61508 standard, four defined SILs range from SIL1 (lowest dependability) to SIL4 (highest dependability). Determining an appropriate SIL for a particular system or function involves assessing various risk factors and potential hazards, aiming to achieve a tolerable risk level by implementing necessary safety measures.

This SIL designation helps ensure that safety systems meet consistent standards of reliability and performance. It’s essential in industries where functional failures can lead to significant harm or catastrophic events, such as chemical processing plants, oil refineries, and nuclear power facilities. The SIL assignment process, often involving methods like risk matrices, risk graphs, and a layer of protection analysis, ensures that the safety instrumented systems (SIS) function correctly during specific dangerous scenarios.

Importance Of Safety Integrity Level (SIL)

The Safety Integrity Level (SIL) is of paramount importance for several reasons:

- Risk Reduction: At its core, SIL is a risk reduction measure. By classifying systems based on their SIL, organizations can ensure that adequate safety measures correspond to the potential severity of a risk.

- Standardization: SIL provides a standardized method to assess and categorize systems’ reliability and safety performance. This standardization allows industries globally to operate on a common understanding and safety criteria.

- Informed Decision Making: Knowing the SIL of a system helps decision-makers allocate resources effectively. They can prioritize systems that require a higher SIL and thus need more robust safety measures.

- Regulatory Compliance: Regulatory bodies mandate many industries to adhere to certain safety standards. Utilizing SIL helps organizations meet these regulatory requirements, avoiding legal repercussions and potential financial penalties.

- Public and Environmental Safety: Especially in industries where accidents can result in significant harm to the environment or the public (like the nuclear, chemical, or petroleum industries), SIL ensures that the highest safety measures are in place to prevent catastrophic events.

- Economic Concerns: Accidents and malfunctions can result in operational halts, damage to equipment, and costly lawsuits. Adhering to the right SIL can prevent these financial setbacks.

- Trust and Reputation: Organizations that rigorously apply SIL standards are more likely to be trusted by partners, stakeholders, and the public. A reputation for safety can be a significant business asset.

- Comprehensive Safety Review: Determining SIL involves thoroughly reviewing potential hazards, ensuring no potential threats are overlooked.

- Continual Improvement: SIL is not just a one-time assessment. It encourages regular reviews and updates to safety measures as technologies and processes evolve.

In essence, the importance of SIL extends beyond mere compliance. It’s a commitment to safety, operational excellence, and the well-being of all involved, from workers within an organization to the world.

What are Safety Integrity Levels?

Safety Integrity Levels (SILs) are a classification system used in functional safety standards to represent the relative level of risk reduction provided by a safety instrumented function (SIF). They indicate the reliability and effectiveness of safety systems in preventing or mitigating hazardous events. SILs are integral to industrial safety standards, ensuring safety systems meet consistent reliability and performance criteria.

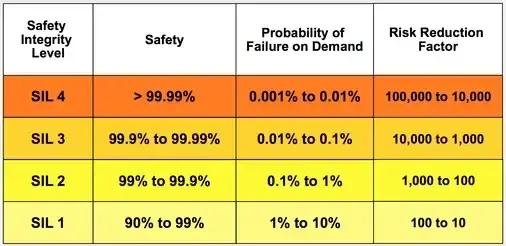

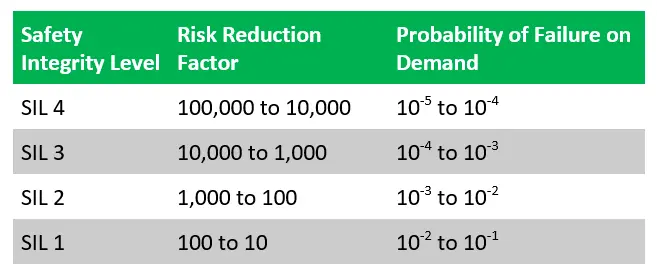

Based on the IEC 61508 standard, there are four defined SILs:

- SIL 1: Represents the lowest level of safety integrity and risk reduction.

- SIL 2: Indicates a higher level of safety integrity than SIL 1.

- SIL 3: Provides even more stringent safety requirements and risk reduction.

- SIL 4: Represents the highest level of safety integrity and risk reduction.

Each increase in SIL level denotes a tenfold improvement in safety performance. The appropriate SIL for a particular system or function is determined by assessing a process or operation’s potential risks and hazards. The goal is to ensure that the level of risk is brought down to a tolerable threshold by implementing the required safety measures.

How To Calculate Safety Integrity Level (SIL)?

The calculation of the Safety Integrity Level (SIL) for a given safety function involves a quantitative and/or qualitative analysis of the risks associated with that function. The exact method for determining the SIL varies depending on industry and standards, but generally, the process follows these steps:

Risk Assessment

- Identify hazards using techniques such as Hazard and Operability Studies (HAZOP).

- Estimate the frequency and severity of potentially hazardous events.

- Considering existing protective measures, determine the risk reduction required to achieve a tolerable risk.

Determine Target SIL

- Use the risk assessment results to determine the required SIL for the safety function. Many organizations use risk matrices, risk graphs, or Layers of Protection Analysis (LOPA) to relate the severity and likelihood of a hazardous event to a required SIL.

- Determine the difference between the inherent and tolerable risks for each identified hazard. This gap represents the risk reduction required and will guide the selection of the appropriate SIL.

Calculate the Probability of Failure on Demand (PFD)

- Estimate the PFD based on system reliability data for the given safety function. PFD represents the likelihood that a safety system will fail to perform its safety function when required.

- Use available data and reliability models for individual components in the safety system to estimate the system’s overall PFD.

Compare PFD with SIL Criteria

International standards, such as IEC 61508, provide PFD ranges for each SIL. Compare the calculated PFD with these criteria to ensure the system meets the requirements for the target SIL.

Iterative Improvement:

If the system does not meet the target SIL based on its PFD, it might be necessary to enhance its design. This can include adding redundancy, using higher-reliability components, or introducing additional layers of protection.

Validation and Verification:

Once the system is designed to meet the target SIL, it must be validated and verified to ensure it performs as intended and meets the required safety standards.

It’s important to note that SIL determination and calculation should be done by professionals trained in functional safety. It should involve multidisciplinary teams to comprehensively evaluate risks and system performance. Also, SIL determination is typically revisited throughout a system’s lifecycle, especially after modifications or when new risk data becomes available.

Problems Inherent In The Use Of Safety Integrity Levels

Safety Integrity Levels (SILs) are instrumental in achieving functional safety in various industries. However, several challenges and problems can arise when applying and interpreting SILs:

- Harmonization Across Standards: Different standards bodies may define or interpret SILs differently, leading to potential confusion and inconsistency in application across industries or regions.

- Process-Oriented Metrics: The derivation of SILs often relies on process-oriented metrics, which can be hard to standardize across varied applications and environments.

- Reliability Estimations: Assigning an SIL based on reliability estimates can be problematic. Estimating the reliability of complex systems, especially over long durations, can be fraught with uncertainty.

- System Complexity: As systems, especially software-driven ones, become more complex, determining their reliability and, by extension, their SIL can become challenging. Complexity often introduces unpredictability.

- Misuse of Terminology: SIL can be taken out of context or misapplied. Statements like “This is a SIL 3 heat exchanger” or “This software is SIL 2” may not truly reflect the holistic safety considerations of a system.

- Dangerous Failure vs. Total Failure: SIL considerations concern dangerous failures, not just failures. It’s essential to distinguish between the two, which can be overlooked.

- Over-reliance on SILs: There’s a risk that some may view achieving a specified SIL as a panacea for all safety concerns. However, safety in complex systems requires a comprehensive approach, of which SIL is just one component.

- Economic Constraints: As the required SIL level increases, the system’s associated costs (both initial and maintenance) also rise, potentially leading to economic pressures that might influence SIL determination.

- Over-Complexity for High SILs: For very high-risk processes requiring SIL 4, the system’s complexity might make it difficult or economically unfeasible to implement. In such cases, reconsidering the process or using non-instrumented safeguards is often better.

Addressing these challenges requires rigorous application of safety standards, continuous training, and a holistic view of safety beyond just achieving a specific SIL.

Applications of Safety Integrity Level (SIL)

Safety Integrity Level, or SIL, is a crucial concept for ensuring the safe operation of various systems. Here are some areas where SIL plays a significant role:

- Industrial Systems: In industries like chemicals, petrochemicals, and pharmaceuticals, process control systems are vital. Any malfunction can lead to severe accidents, making SIL evaluations essential to ensure safety.

- Transport: Whether it’s the railway, aviation, or automotive sectors, transportation involves high risks. SIL ensures that safety measures in these systems are reliable.

- Healthcare: Medical devices and equipment directly impact patients’ lives. Ensuring their safety through SIL assessment is crucial.

- Energy Sector: Nuclear power plants, for instance, have extremely high risks. The application of SIL ensures that these plants operate safely.

- Natural Resource Extraction: Oil and gas extraction and refining systems can be hazardous. SIL helps in reducing potential threats.

SIL serves as a standard to assess and categorize how effective safety functions or systems are in all these areas. It’s like a safety grade. After identifying any possible hazards and risks in a system, SIL evaluations help decide how safe the system is and what improvements might be needed. It provides a roadmap for designing, developing, and testing safety systems to ensure they hit the safety benchmarks.

Example of Determining SIS, SIF, and SIL

Imagine a factory that uses a pressure vessel to hold a flammable liquid. The vessel’s pressure is normally kept in check by the Basic Process Control System (BPCS). But if this system fails, the pressure inside the vessel might rise uncontrollably. This could lead to the vessel breaking, releasing the flammable liquid, and potentially causing a fire or explosion.

To manage such a risk, the facility might introduce a Safety Instrumented System (SIS). This system would work separately from the BPCS to act as a safety net in case of failures. Its job would be to detect and handle situations where the vessel’s pressure goes too high.

The SIS ensures safety through a Safety Instrumented Function (SIF). This function could involve:

- A pressure transmitter: A device that monitors the vessel’s pressure.

- A logic solver: A controller that decides what actions to take based on the transmitter’s readings.

- A solenoid valve: A valve that, when activated, releases the vessel’s contents to a safe place (like a storage tank or a flare stack) to reduce the pressure.

Based on a risk assessment, let’s say the facility determines that it needs to reduce the risk of vessel failure by a factor of 100. This would mean aiming for a Safety Integrity Level (SIL) of 2 for the SIF. In technical terms, the function has a Probability of Failure on Demand (PFD) of 10^-2, meaning it’s 99% reliable. Simply put, the safety system is designed to fail to act only 1 out of 100 times when required. This SIF, designed to this standard, would significantly decrease the risk of a hazardous incident at the facility.

So, in this example, the SIS is like a safety net for the vessel, the SIF is the specific function (monitoring and releasing pressure) to prevent over-pressurization, and SIL 2 is the reliability standard to which the SIF is designed.

Conclusion

Safety Integrity Levels (SIL) represent more than just a technical metric; they are a testament to an industry’s commitment to prioritizing safety, mitigating risks, and ensuring the well-being of its personnel and the broader community. As we’ve journeyed through the nuances of SIL, its inherent challenges, and real-world applications, it becomes evident that understanding and implementing SIL is indispensable for industries operating with intricate systems. Not only does it serve as a guiding principle in design and operation, but it also acts as a benchmark for continuous improvement.

As technology advances and industries evolve, so will the tools and methods to ensure safety. However, the core ethos behind SIL—to prioritize human life and environmental protection—remains unwavering. By embracing SIL and its principles, industries safeguard their present and pave the way for a safer, more sustainable future.