Slips, trips, and falls are among the leading causes of workplace injuries across construction sites, warehouses, manufacturing plants, and industrial facilities. These incidents often seem minor, yet they account for thousands of serious injuries and hundreds of fatalities every year. A well-prepared toolbox talk on slips, trips, and falls helps workers understand how these hazards occur, how to recognize them, and how to prevent them through safe behaviors and proper housekeeping.

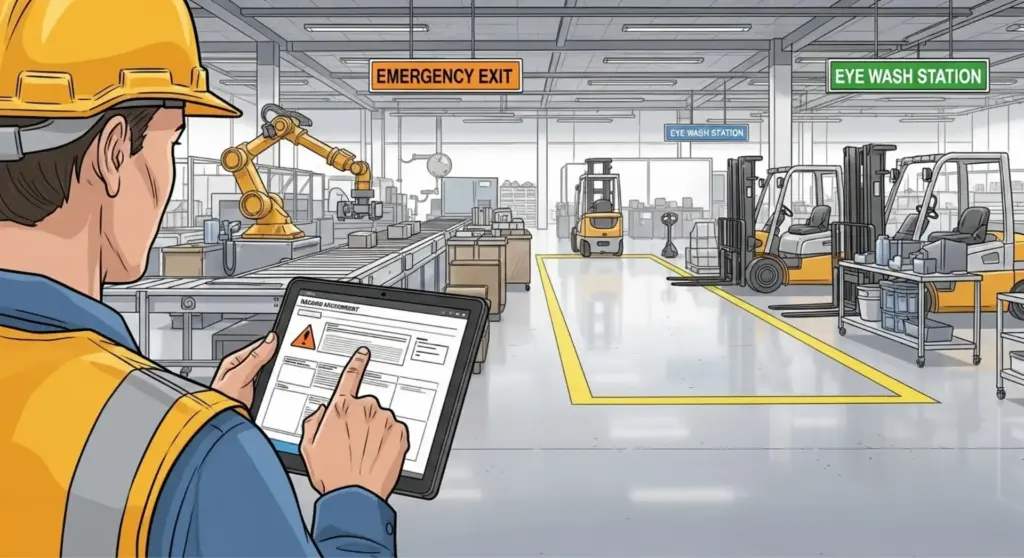

This detailed guide explains why this topic matters, outlines common hazards, and provides practical prevention strategies. You’ll also find a daily safety checklist and a full hazard assessment template you can use to reinforce key points during your toolbox talk.

Why Slips, Trips, and Falls Matter in the Workplace

Slips, trips, and falls are not “simple accidents.” They are among the most frequent and costly workplace incidents. According to industry statistics:

- Slip, trip, and fall incidents accounted for 885 workplace deaths in 2023.

- They represent around 15% of all accidental workplace fatalities, second only to motor vehicle incidents.

- More than one million workers suffer non-fatal slip, trip, or fall injuries each year.

- These incidents make up one in six lost-time injuries, with many cases leading to an average of 11 days away from work.

Slips occur when traction between footwear and the floor is reduced—usually due to wet, oily, or slick surfaces. Trips happen when a worker’s foot catches on an obstruction or uneven ground. Both can result in falls, which may be same-level or from an elevation. Same-level falls occur more often, but falls from heights are typically more severe.

Understanding how these accidents happen—and how to prevent them—can dramatically reduce injuries and improve workplace safety.

Common Causes of Slips, Trips, and Falls

During your toolbox talk, review these common hazards and encourage workers to discuss examples from their own job site.

Wet or Oily Surfaces

- Spills from drinks, leaking equipment, coolant, or lubricants

- Rainwater or snow tracked indoors

- Condensation in humid areas

- Wet surfaces after cleaning

Weather Hazards

- Ice, snow, or freezing rain

- Mud and wet conditions around construction zones

- Melted snow around entrances

Uneven or Damaged Flooring

- Cracked concrete, potholes, broken tiles

- Uneven surfaces in outdoor lots or construction zones

- Raised edges or curled floor mats

Clutter and Poor Housekeeping

- Tools, materials, packaging, or debris in walkways

- Strapping, shrink-wrap, or pallet debris underfoot

- Unsecured hoses and tools left after tasks

Cords and Cables

- Extension cords and hoses stretched across walkways

- Air hoses, welding leads, and power cables

- Loose cords hanging in walk areas or doorways

Poor Lighting

- Burnt-out bulbs in stairwells or hallways

- Shadows in corners or behind equipment

- Insufficient lighting during night or maintenance shifts

Obstructed Vision and Carrying Loads

- Carrying bulky items that block the view

- Pushing carts stacked too high

- Moving materials in tight or congested spaces

Improper Footwear

- Smooth, worn-out soles

- Inappropriate footwear for industrial or outdoor work

- Lack of slip-resistant tread

Unsafe Ladders or Stairs

- Damaged or unstable ladders

- Missing handrails

- Carrying tools while climbing

- Skipping steps or rushing

Identifying hazards and correcting them early is the first step in preventing accidents.

Prevention: Best Practices to Avoid Slips, Trips, and Falls

Preventing slips and trips requires good housekeeping, proper equipment, safe behavior, and awareness. Encourage workers to act immediately when they see a hazard and to consistently follow these best practices.

1. Good Housekeeping and Walkway Maintenance

A clean workplace is a safe workplace.

- Clean spills immediately and mark wet floors with signage.

- Keep aisles and exits free of cords, debris, materials, and tools.

- Secure loose mats or rugs.

- Repair uneven flooring, holes, or rough patches.

- Improve lighting in dark or high-traffic areas.

- In winter, remove snow/ice promptly and apply salt or sand.

- Use absorbent material around leaking equipment.

Proactive housekeeping throughout the day—rather than waiting until shift-end—significantly reduces hazards.

2. Proper Footwear and PPE

Footwear is your first line of defense.

- Require slip-resistant, supportive work boots.

- Avoid smooth-soled shoes.

- Clean mud, oil, or debris from boot treads regularly.

- Replace boots when soles are worn.

- Use overshoes or traction aids during rainy or icy conditions.

Encourage workers to inspect footwear regularly and follow company footwear policies.

3. Safe Walking Practices and Awareness

Human behavior plays a major role in prevention.

- Walk—don’t run—on job sites.

- Slow down when conditions are slippery.

- Scan the path ahead for spills, cords, uneven ground, or clutter.

- Use handrails on stairs and elevated platforms.

- Take small, careful steps on wet surfaces.

- Ensure loads do not block your view; use carts or get assistance.

- Remain alert and avoid distractions while walking.

Small adjustments in daily movement can dramatically reduce incidents.

4. Fall Protection for Elevated Work

Falls from heights are the most severe type of fall.

- Wear fall protection (harness, lanyard) when working above required height thresholds.

- Inspect all fall protection gear before each use.

- Ensure guardrails, toe boards, or barricades are installed where required.

- Cover or guard floor openings and skylights.

- Set up ladders on stable surfaces; maintain three-point contact.

- Never carry tools in your hands while climbing.

- Only trained personnel should erect or use scaffolding.

Review fall protection rules thoroughly if your job site includes elevated work.

5. Build a “See Something, Say Something” Culture

Encourage workers to:

- Report hazards immediately

- Clean or mark hazards if safe to do so

- Share near-miss incidents with supervisors

- Suggest improvements to housekeeping or workflow

A team-oriented safety environment keeps everyone alert and proactive.

Slip, Trip, and Fall Prevention Checklist

Use this checklist at daily huddles or post it on a jobsite board.

- Housekeeping is complete: walkways clear, spills cleaned, debris removed.

- Floor surfaces are in good condition and dry.

- Outdoor walkways are salted or cleared as needed.

- Lighting is adequate in all work and travel areas.

- Cords/hoses are routed safely or secured with covers.

- Ladders and stairs are in good repair; handrails are secure.

- Workers are wearing slip-resistant footwear.

- Fall protection gear is used at heights and inspected beforehand.

- Workers are following safe walking practices.

- Any hazards identified are corrected or reported immediately.

Slip, Trip, and Fall Hazard Assessment Template

A more thorough inspection should be done weekly or monthly using a structured hazard assessment. Include sections such as:

- Footwear compliance

- Outdoor grounds and parking areas

- Indoor flooring and drainage

- Lighting and visibility

- Equipment and machinery leak checks

- Housekeeping and storage practices

- Ladder and stairway conditions

- Inclement weather controls

- Spill response supplies

- Training status and incident review

Mark each hazard as Yes/No and assign corrective actions with priority levels.

Conclusion: Step Up for Safety

Slips, trips, and falls are highly preventable when workers stay alert, use proper footwear, maintain clean work areas, and follow safety procedures. Encourage your team to take ownership of their environment, report hazards immediately, and keep safety front-of-mind throughout the day. A strong safety culture prevents injuries, protects workers, and boosts productivity for the entire job site.

Ask the team to share examples of slip/trip hazards they’ve noticed recently and how they were resolved. Real stories help reinforce the importance of today’s topic.