Understanding the importance and intricacies of container labeling is essential, especially when dealing with hazardous chemicals. Effective labeling can serve as a communication tool to highlight the physical and health hazards associated with chemical usage in the workplace. The information provided on a container label can vary greatly, often contingent on the type of container and its specific use.

This blog post delves into the Hazard Communication Standard (HCS) 2012 requirements, emphasizing the labeling stipulations for four main container types: Shipped/primary containers, Workplace/secondary containers, Stationary containers, and Portable containers. We aim to equip you with a comprehensive understanding of these requirements to ensure safe practices and regulatory compliance in your workplace. Let’s get started!

Types of Containers and Labels

Container labeling can be a very effective method to communicate the physical and health hazards of chemicals used in the workplace. The information on a container label will vary depending on the container type and how it is used. This section will discuss labeling requirements under the HCS 2012 labeling requirements.

We’ll look at the labeling requirements for each of the four types of containers listed below:

- Shipped/primary containers

- Workplace/secondary container

- Stationary containers

- Portable containers

Shipped ‐ Primary Container Label Requirements

Under the new HCS 2012, labels on containers shipped from manufacturers or distributors must be labeled, tagged, or marked with the following six items:

- Product Identifier – This should include the chemical identity of the substance.

- Signal Word ‐ Signal words used in GHS are “Danger” and “Warning.” The danger is for the more severe hazard categories.

- Hazard Statements ‐ This is a phrase assigned to a hazard class and category that describes the nature of the hazards of a hazardous product and the degree of the hazard.

- Pictograms include symbols plus other elements, such as a border, background pattern, or color that conveys specific information.

- Precautionary Statements ‐ These are phrases (and/or pictograms) that describe the recommended measures to minimize or prevent adverse effects from exposure to a hazardous product.

- Supplier Identification – Includes the name, address, and telephone number of the manufacturer or supplier of the substance or mixture.

Workplace or Secondary Container Labeling

Most employers use the primary containers they purchase to store and use chemicals.

However, they may also use their containers, such as coffee cans, drums, plastic jugs, spray bottles, etc., to store and use smaller quantities of chemicals they purchase. These are called workplace or secondary containers.

Make sure your secondary containers are properly labeled, not only to protect employees but to avoid OSHA citations. One of the most frequent citations of HCS 2012 is “improperly labeled secondary containers.” OSHA sees this all the time, and whatever OSHA sees the most, they cite the most: Remember that.

The employer must ensure that each workplace or secondary container of hazardous chemicals the workplace is labeled, tagged, or marked with either:

- The information required on shipping container labels; or,

- Product identifier and words, pictures, symbols, or a combination thereof, which provide at least general information regarding the hazards of the chemicals and specific information regarding the physical and health hazards of the hazardous chemical.

Portable Container Labeling

It is important to know that portable containers must be under the employee’s positive control. If the employee walks away from the container and loses control of the chemical, it must be labeled as a workplace/secondary container.

Portable containers are used to transfer hazardous chemicals from labeled containers and are intended only for the immediate use of the employee who performs the transfer. The employer is not required to label portable containers into which hazardous chemicals are transferred from labeled containers and intended only for the immediate use of the employee who performs the transfer.

Drugs dispensed by a pharmacy to a health care provider for direct administration to a patient are exempted from labeling.

Labeling Solid Materials

For solid metal (such as a steel beam or a metal casting), solid wood, or plastic items that are not exempted as articles due to their downstream use, or shipments of whole grain, the required label may be transmitted to the customer at the time of the initial shipment. They need not be included with subsequent shipments to the same employer unless the information on the label changes.

For example, treated lumber is covered since the lumber is not completely cured at the time of shipment, and the hazardous chemical will, to a varying degree, off-gas during shipment and be available for exposure to employees. Railroad ties treated with creosote should have an accompanying safety data sheet (SDS) when shipped.

HCS 2012 Pictogram Requirements

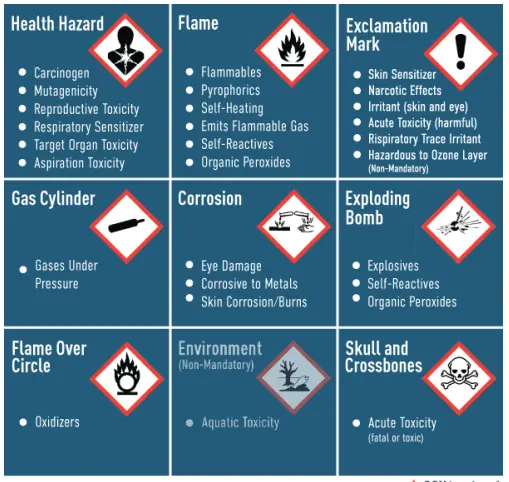

The HCS 2012 requires GHS pictograms on labels to alert users of the chemical hazards they may be exposed to. Each pictogram consists of a symbol on a white background framed within a red border and represents a distinct hazard(s). The pictogram on the label is determined by the chemical hazard classification.

While the GHS uses nine pictograms, OSHA will only enforce the use of eight. The environmental pictogram is not mandatory but may be used to provide additional information. Workers may see the ninth symbol on a label because label preparers may choose to add the environment pictogram as supplementary information

HCS Pictograms and Hazards

Conclusion

Container labeling is critical to maintaining safety and ensuring effective communication in the workplace, especially where hazardous chemicals are involved. The labeling requirements set out in the HCS 2012 provide a robust framework to ensure clarity, uniformity, and comprehensiveness of hazard information across various container types, including shipped/primary containers, workplace/secondary containers, stationary containers, and portable containers.

By adhering to these guidelines, employers can significantly minimize the risk of mishandling dangerous substances, ultimately protecting employees and the working environment. Remember, an informed workplace is a safer workplace. As we evolve our safety practices, let’s commit to keeping ourselves updated and prioritizing the proper labeling of containers in our workplaces.