In the dynamic world of the workplace, safety often acts as the unsung guardian of productivity, morale, and operational efficiency. Yet, despite well-established protocols and safety guidelines, certain behaviors and decisions can endanger individuals and the larger team. These behaviors, termed ‘unsafe acts,’ are more common than most realize and can swiftly transform a regular workday into a disastrous one. But what exactly constitutes an unsafe act? And how can such actions be identified and curbed before they lead to dire consequences?

This blog delves into unsafe acts, highlighting 10 prominent examples that every employer and employee should know. By understanding these pitfalls, businesses can better navigate workplace safety challenges, ensuring a secure and harmonious environment.

What are Unsafe Acts In The Workplace?

Unsafe acts refer to any behavior, action, or decision by individuals that deviate from accepted safety protocols, standards, or procedures, thereby increasing the risk of accidents, injuries, or harm in a particular environment, typically the workplace. These acts result from human error and can either be unintentional (e.g., due to a lack of knowledge) or deliberate (e.g., ignoring safety protocols).

Importance of Addressing Unsafe Acts:

- Prevention of Accidents and Injuries: Addressing and minimizing unsafe acts can lead to a significant reduction in the number of workplace accidents, injuries, and fatalities.

- Economic Considerations: Accidents and injuries can result in significant business costs, including medical expenses, compensation claims, increased insurance premiums, and potential legal actions.

- Enhanced Productivity: A safe working environment, free from disruptions caused by accidents, can lead to more consistent and efficient production and operations.

- Moral and Ethical Responsibility: Employers have a moral and ethical responsibility to ensure the safety and well-being of their employees. Addressing unsafe acts aligns with this responsibility.

- Improved Employee Morale: A safe working environment promotes positive employee morale. Workers will likely be more motivated and satisfied when they believe their employer prioritizes their safety.

- Reduction in Downtime: Accidents can result in downtime, disrupting the regular flow of operations. Addressing unsafe acts can minimize these disruptions.

Understanding and addressing unsafe acts is pivotal to any comprehensive safety and health management system. By focusing on the root causes and conditions leading to unsafe behaviors, organizations can create a safety culture, minimizing risks and promoting overall well-being for all organization members.

10 Different Examples Of Unsafe Acts In The Workplace

Unsafe acts in the workplace are behaviors or decisions by employees that increase the risk of accidents or injuries. Addressing these acts can significantly improve safety and productivity. Here are ten examples of unsafe acts and how to avoid them:

1. Not Using Personal Protective Equipment (PPE):

Personal Protective Equipment, commonly known as PPE, is the frontline defense against many workplace hazards. PPE ranges from safety goggles and helmets to gloves and respiratory masks. Employees who neglect to use PPE expose themselves to potential harm, from chemical burns to physical injuries. To ensure optimal use, it’s vital that organizations not only provide PPE but also ensure that it fits each employee correctly.

Ill-fitting PPE can be as hazardous as not wearing any; for example, a loose-fitting mask might not protect against inhalation of harmful substances. Moreover, PPE should be comfortable for long-term use. If it’s not, employees might be tempted to remove it. Lastly, the mere provision of PPE isn’t enough. Regular training sessions should be held, reinforcing the importance of PPE and teaching employees the correct way to wear and maintain them.

2. Operating Machinery Without Proper Training:

Machinery, especially in industrial settings, can be complex and dangerous if mishandled. Operating machinery without the proper knowledge can lead to severe accidents, damaging the equipment, injuring the operator, or even harming nearby colleagues. It’s not just about knowing which buttons to push; operators must understand the machine’s intricacies, potential risks, and safety precautions.

Therefore, companies should have a strict policy of not allowing untrained individuals to operate machinery. This training shouldn’t be a one-time event. As machinery gets updated, or even as time goes by, refresher courses should be given to ensure that all operators are current with their knowledge and skills.

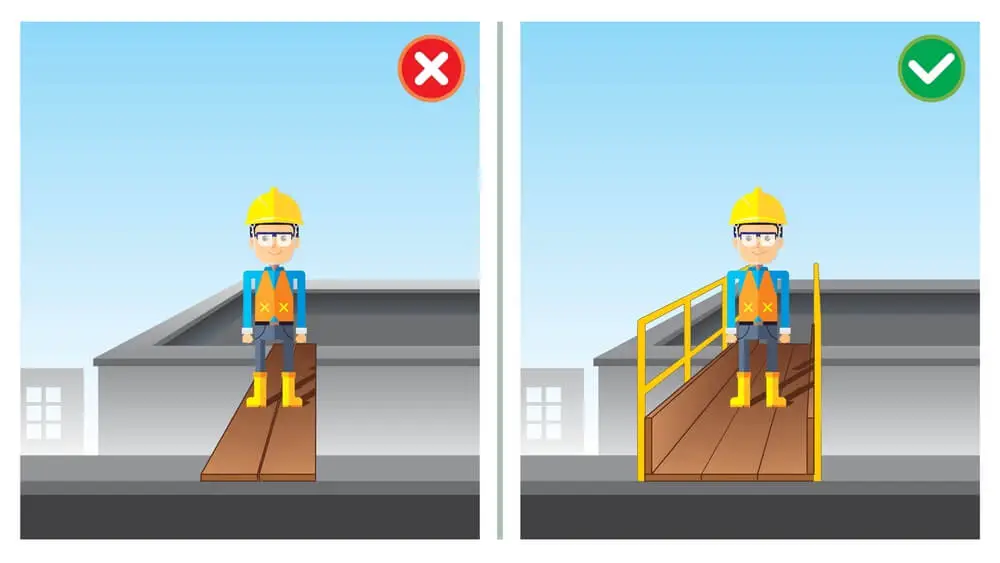

3. Bypassing Safety Protocols or Devices:

Every safety protocol or device in a workplace is there for a reason. They are designed based on past experiences, potential risks, and industry best practices to protect workers from harm. When employees bypass these measures, thinking it might save time or because they believe they know better, they jeopardize their safety and that of their peers.

Organizations should instill a deep respect for safety procedures to counteract this behavior. This respect can be cultivated through regular safety briefings, showcasing accident statistics, or even sharing anecdotes of accidents that could have been prevented by following protocols. Additionally, safety devices should be regularly checked and maintained. A malfunctioning safety device can sometimes be worse than not having one, as it provides a false sense of security.

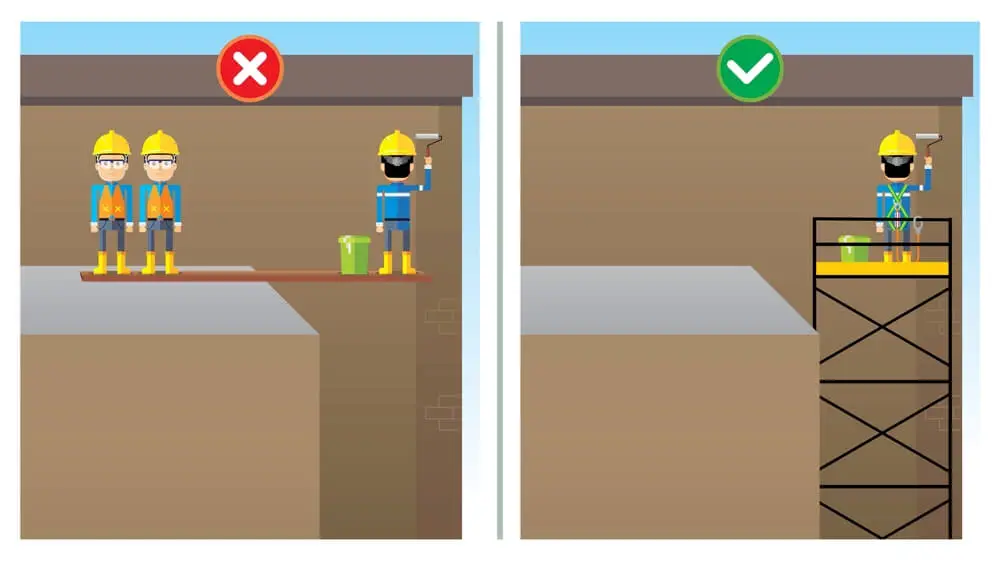

4. Using Damaged Tools or Equipment:

Damaged tools or equipment are accidents waiting to happen. A frayed wire can lead to electrocution, and a broken ladder can cause a fall. These tools might sometimes be used because employees are unaware of the dangers they present, or they might not have a system to report and replace damaged tools.

Regular inspections can help identify problematic equipment before it causes an accident. However, inspections alone aren’t enough. Employees should be encouraged to report any damaged tools they come across immediately. This reporting system should be clear and straightforward, ensuring the damaged tools are repaired or replaced promptly.

5. Not Reporting Hazards or Near Misses:

Hazards and near misses are precursors to actual accidents. When left unaddressed, they present a lurking danger in the workplace. The challenge here is that employees sometimes fear retribution for reporting hazards, thinking they might be blamed for causing them. Or, they might consider a near miss a non-event since nothing “actually” happened. This mindset needs to change.

Organizations should create a culture where reporting hazards and near misses is seen as a proactive safety measure, not an admission of guilt. To achieve this, companies can establish a non-punitive reporting system where employees feel safe and encouraged to share potential hazards without fearing repercussions. Through this, organizations can identify and rectify potential dangers before they escalate into real threats.

6. Horseplay or Distracting Others:

Horseplay in the workplace isn’t just about jovial antics or pranks; it’s a matter of safety. Such behavior can quickly lead to accidents, from simple trips and falls to more severe injuries, especially in environments with machinery or other potential hazards. Distracting others, whether through loud noises, unexpected actions, or irrelevant conversations, can break an individual’s concentration, leading to mistakes or mishandling of equipment.

Organizations can deter such actions by fostering a professional environment. This involves setting clear expectations of behavior and directly addressing any actions that deviate from the expected standard. By educating employees about the potential risks and consequences of horseplay and distractions, businesses can underline the importance of maintaining focus and decorum, ensuring safety for all.

7. Improper Lifting Techniques:

Back injuries are among the most common in many workplaces, often resulting from improper lifting techniques. An employee bending wrongly to pick up a heavy object can lead to sprains, muscle pulls, or more severe spinal injuries. While the object’s weight is a factor, the method of lifting plays a significant role in determining the risk.

To address this, organizations should offer training on proper lifting techniques and the principles of ergonomics, ensuring that employees understand the mechanics of their body and how best to leverage strength without causing harm. Where possible, lifting aids, such as trolleys or forklifts, should be available. Moreover, it’s essential to cultivate a culture where employees feel no hesitation in seeking help or using aids when handling heavy objects.

8. Working Under the Influence of Alcohol or Drugs:

Working under the influence is a critical concern for workplaces. Impaired judgment, slowed reaction times, and decreased motor coordination are just a few of the issues associated with substance use, making the individual a potential risk to themselves and others. This is especially true in environments involving machinery, vehicles, or precision-based tasks.

To counteract this, companies should have a clear and strict drug and alcohol policy, explicitly stating the consequences of being under the influence at work. However, it’s equally essential to approach this issue with empathy. Offering support programs or resources for those struggling with substance abuse can be a proactive step, ensuring employees have a path to recovery.

9. Ignoring Warning Labels or Instructions:

Warning labels and instructions are concise communicators of safety. They inform users about potential product, machine, or chemical hazards. However, if these labels are ignored or misunderstood, it can lead to misuse and consequent accidents.

To ensure these labels serve their purpose, they should be clear, visible, and presented in a language or format universally understood within the workplace. Regular training sessions can help reinforce the importance of these warnings. Employees can grasp the potential consequences of ignoring such instructions through practical demonstrations or examples.

10. Overworking or Not Taking Breaks:

Overworking isn’t just an issue of diminishing productivity; it’s a significant safety concern. Fatigued employees might experience decreased alertness, slower reaction times, and impaired decision-making. In high-risk environments, this can be catastrophic. Over time, chronic overworking can also lead to burnout, long-term health issues, and decreased morale.

Monitoring workloads is a proactive step in recognizing potential overworking. Managers and supervisors should ensure that employees take regular breaks, especially during long shifts or demanding tasks. By promoting a culture where rest is valued as much as work, organizations can ensure that employees remain refreshed, alert, and ready to tackle their tasks safely.

Conclusion

Navigating the intricate web of workplace operations requires more than just skill and efficiency; it demands a relentless commitment to safety. Unsafe acts, intentional oversights or inadvertent errors can disrupt this delicate balance, posing threats to the individuals involved and the broader team and organizational machinery.

As we’ve explored in this blog, these acts can manifest in various forms, from neglecting personal protective gear to working under the influence. Recognizing, understanding, and actively addressing these ten examples is paramount. By fostering a culture of awareness and proactive safety measures, organizations can ensure that the workplace remains a haven of productivity and well-being, free from the shadows of preventable hazards.