Confined spaces can be found in various industries, including manufacturing, construction, and agriculture. These spaces are typically small, enclosed areas not designed for continuous human occupancy. Working in confined spaces can present several hazards that can lead to serious injury or death. Workers and employers must understand the potential hazards of confined spaces and take the necessary precautions to avoid them.

In this blog post, we will explore 13 common confined space hazards and provide tips on how to avoid them. Whether you are a worker or an employer, this information can help create a safer work environment and prevent accidents in confined spaces.

Importance Of Safety In Confined Space

Confined space safety is important because working in confined spaces can be very hazardous. A confined space is a space that is large enough for a worker to enter and perform work but has limited means of entry or exit and is not designed for continuous occupancy. Some examples of confined spaces include storage tanks, pipelines, sewers, silos, and tunnels.

The hazards of confined spaces can include poor air quality, limited visibility, and the potential for fires, explosions, or suffocation. Workers entering confined spaces may also risk being trapped, injured, or killed.

According to the International Labour Organization (ILO), around 15% of all fatal workplace accidents are caused by confined spaces. In the United States, the Occupational Safety and Health Administration (OSHA) reports that 92 fatalities occur yearly in confined spaces. In the European Union, it is estimated that around 60 fatalities occur each year in confined spaces.

It is essential for employers and workers to take appropriate precautions to ensure the safety of those who work in confined spaces. This includes implementing safety procedures and providing appropriate training and equipment to workers who may be required to enter confined spaces. Employers should also ensure that workers are aware of the risks associated with working in confined spaces and are equipped with the knowledge and tools they need to safely perform their work.

Confined Space Hazards And How To Avoid Them

Confined spaces present a unique set of hazards that can be difficult to identify and mitigate. However, with proper training and safety protocols in place, these hazards can be avoided. Below are 13 common hazards associated with confined spaces and tips on how to avoid them:

1. Lack of Oxygen

A lack of oxygen is one of the most common hazards associated with confined spaces. This occurs when the space has a limited supply of fresh air or when the air is contaminated and cannot sustain human life. This can lead to suffocation, as well as other serious health issues.

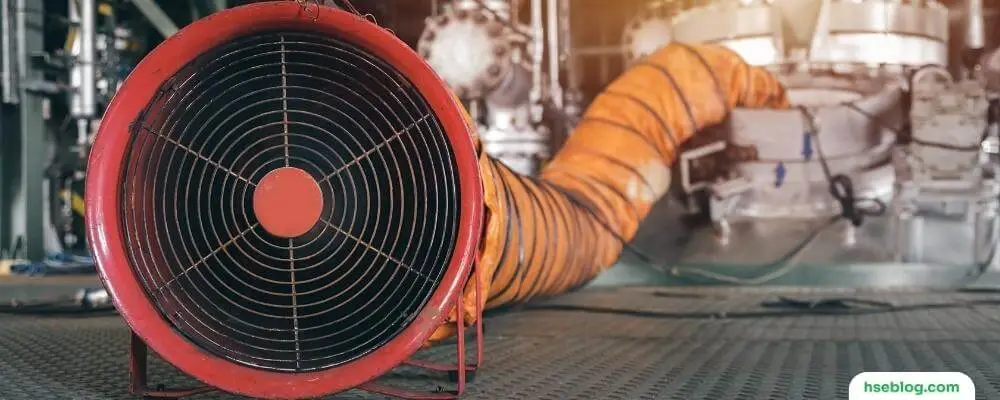

To prevent this hazard, it is important to ensure that proper ventilation is in place. This can be achieved by using fans, blowers, or other ventilation equipment to circulate fresh air into the space. Before entering the confined space, it is also essential to test the air quality using a gas detector to determine the level of oxygen present.

OSHA regulations require that the oxygen concentration in a confined space be between 19.5% and 23.5%. If the oxygen level falls below 19.5%, it is considered oxygen deficient and can be fatal. If the oxygen level is too high, above 23.5%, it can lead to combustion.

In addition to ventilation and air quality testing, it is also crucial to have a rescue plan in place in case of an emergency. All workers who enter confined spaces should receive proper training on recognizing the signs of oxygen deficiency and how to respond in an emergency. By taking these steps, it is possible to prevent a lack of oxygen from becoming a serious hazard in confined spaces.

2. Toxic Atmospheres

If inhaled, confined spaces such as tanks, silos, and sewers can often contain toxic gases, vapors, or dust that can cause serious health problems. These toxic atmospheres can be caused by various sources, such as chemicals, rotting organic material, or waste products. Workers entering these spaces must be aware of the potential hazards and take precautions to protect themselves.

One of the most important steps in avoiding toxic atmospheres is to test the air quality before entering space. This can be done using a gas detector that can measure the concentration of harmful gases such as carbon monoxide, hydrogen sulfide, and methane. If the air quality is unsafe, workers should not enter the space until it has been properly ventilated.

In addition to testing the air quality, workers must ensure the space is well-ventilated. This means there must be a sufficient supply of fresh air flowing into the space to dilute and remove harmful gases or vapors. Ventilation can be achieved through natural ventilation, such as opening windows or using fans, or mechanical ventilation, such as a blower or an exhaust system.

It is also important for workers to wear appropriate personal protective equipment (PPE) when entering confined spaces with toxic atmospheres. This may include respiratory protection such as respirators, eye and face protection, and gloves.

Finally, workers should be properly trained in confined space entry procedures and emergency response protocols if an incident occurs. This can include having a standby person outside the confined space who can provide assistance or summon emergency services if needed.

3. Fire and Explosion

Confined spaces containing flammable or combustible materials pose a significant risk of fire or explosion, leading to severe injuries, fatalities, and property damage. Ignition sources such as open flames, sparks, static electricity, and hot surfaces must be eliminated before entering such spaces.

Employers must conduct a thorough hazard assessment of the confined space before entry to prevent fire or explosion. The assessment should identify all potential ignition sources and hazardous materials present in the space. If flammable or combustible materials are present, they should be removed, and the space should be adequately ventilated to reduce the risk of a fire or explosion.

Eliminating ignition sources may involve isolating electrical and mechanical equipment, using explosion-proof equipment, grounding and bonding all equipment and tools, and prohibiting smoking or using open flames in confined spaces.

It is crucial to use appropriate personal protective equipment (PPE) such as fire-retardant clothing, respiratory protection, and eye and ear protection when working in confined spaces that pose a fire or explosion hazard. Workers must also receive adequate training in safe work practices, emergency procedures, and the proper use of PPE.

Regular monitoring of the confined space for hazardous conditions such as combustible gases, vapors, or dust is essential to ensure that the area remains safe for workers. If hazardous conditions are detected, workers must evacuate the space immediately, and appropriate measures must be taken to eliminate the hazard before re-entry.

4. Engulfment

Engulfment is a hazardous condition in confined spaces where workers can be buried or trapped in sand, water, grain, or other substances. This can happen quickly and without warning, often resulting in serious injury or death. Engulfment can occur due to improper entry and exit procedures, inadequate ventilation, and lack of communication and monitoring systems.

Employers must establish proper procedures for safe entry and exit to avoid engulfment hazards in confined spaces. This can include using appropriate personal protective equipment, such as respirators or harnesses, to protect workers from hazards like suffocation or drowning. Employers should also establish communication protocols between workers inside the confined space and those outside to ensure that everyone is aware of the situation and can respond quickly in an emergency.

In addition to these procedures, employers should ensure that the confined space is properly ventilated to prevent the accumulation of hazardous gases and vapors. Monitoring equipment, such as gas detectors or air monitors, should also ensure that the air quality inside the space is safe for workers.

To further reduce the risk of engulfment, employers should properly train workers on the hazards associated with confined spaces, including recognizing and responding to an emergency. Workers should also be trained in proper entry and exit procedures, equipment, and communication protocols.

5. Electrical Hazards

Confined spaces such as tanks, silos, and storage vessels often contain electrical equipment and wiring, posing a significant worker hazard. Electrical hazards in confined spaces can arise from various sources, such as exposed wires, damaged insulation, and faulty electrical equipment.

To prevent electrical hazards, it is essential to take appropriate safety measures before entering a confined space. The following steps can help avoid electrical hazards in confined spaces:

- Identify all potential sources of electrical hazards in the confined space, such as electrical wiring, equipment, and power sources.

- Ensure all electrical equipment in the confined space is properly grounded and bonded to prevent electrical shock or electrocution.

- Test and verify that all electrical equipment is de-energized and locked/tagged out before entering the confined space.

- Use non-sparking tools and equipment to reduce the risk of igniting flammable gases or vapors.

- Wear appropriate personal protective equipment (PPE) such as electrical gloves, face shields, and protective clothing to protect against electrical hazards.

- Implement safe work procedures and practices for working with electrical equipment in confined spaces, such as using a buddy system, having a rescue plan, and providing appropriate training to workers.

- Ensure that the confined space is well-ventilated to reduce the risk of explosions or fires caused by electrical equipment.

- Use appropriate lighting and ensure that all electrical equipment and wiring is properly insulated and protected from physical damage.

- Regularly inspect and maintain electrical equipment in confined spaces to ensure it is in good working condition and does not pose a hazard.

- Provide adequate warning signs and labels to indicate the presence of electrical hazards in the confined space.

Electrical hazards are a significant risk in confined spaces, and it is essential to take appropriate safety measures to prevent them. Proper identification, testing, grounding, PPE, and maintenance of electrical equipment can significantly reduce the risk of electrocution or electrical shock. Additionally, implementing safe work procedures and practices and providing appropriate training to workers can help prevent accidents and injuries in confined spaces.

6. Physical Hazards

Physical hazards are among the most common risks of working in confined spaces. Workers can risk being trapped, crushed, or struck by moving machinery or equipment, resulting in serious injuries or even death. Establishing proper safety procedures and implementing lockout/tagout procedures is essential to prevent physical hazards.

Lockout/tagout procedures involve isolating energy sources to prevent the unintentional startup of machinery or equipment. These procedures should be followed before entering a confined space and should include the following steps:

- Identify and evaluate all potential physical hazards in the confined space, including moving machinery, equipment, or materials that could cause crushing or trapping injuries.

- Establish a lockout/tagout program to isolate energy sources, such as electrical, hydraulic, pneumatic, or mechanical, before entering the confined space.

- Develop a written procedure for lockout/tagout that identifies the specific energy sources to be controlled, the sequence of steps to be followed, and the authorized employees who will perform the procedure.

- Train workers on the lockout/tagout procedure and ensure they understand the importance of following it correctly.

- Ensure that all workers working in the confined space know the lockout/tagout procedure and the specific hazards associated with the space.

- Provide workers with appropriate personal protective equipment, such as hard hats, safety glasses, and gloves, to protect against physical hazards.

- Use non-sparking tools and equipment to reduce the risk of igniting flammable gases or vapors.

- Implement safe work practices and procedures for working with machinery and equipment in confined spaces, such as using a buddy system, providing adequate lighting, and having a rescue plan.

- Regularly inspect and maintain machinery and equipment in confined spaces to ensure it is in good working condition and does not pose a hazard.

- Provide adequate warning signs and labels to indicate the presence of physical hazards in the confined space.

Physical hazards can be significant risks in confined spaces, and it is essential to establish proper safety procedures, including lockout/tagout, to prevent accidents and injuries. Identifying and evaluating potential hazards, developing written procedures, providing appropriate training and PPE, and implementing safe work practices and procedures can significantly reduce the risk of physical hazards in confined spaces.

7. Residues Left In Tanks

When tanks, vessels, and other enclosed spaces are emptied, residues of chemicals or other materials may remain. These residues can emit hazardous gases, fumes, or vapors that can cause serious health problems or even death.

Some examples of hazardous substances found in tank residues include hydrogen sulfide, methane, ammonia, and carbon monoxide. These substances can cause respiratory problems, asphyxiation, and other health issues.

To avoid this hazard, it’s essential to properly clean and ventilate enclosed spaces before entry. This should be done by trained professionals using appropriate equipment and following established procedures. Workers should never enter an enclosed space without proper testing and monitoring for hazardous gases, and they should always wear appropriate personal protective equipment.

In addition to proper cleaning and ventilation, it’s also important to properly label and store chemicals and other materials to prevent the buildup of residues in enclosed spaces. Regular inspections of tanks, vessels, and other confined spaces can help identify potential hazards before they become a problem.

8. Extreme Temperatures

Extreme temperatures can be a significant hazard in confined spaces, with both hot and cold temperatures presenting a risk of heat or cold stress to workers. Heat stress occurs when the body’s temperature regulation mechanisms are overwhelmed, causing the body’s core temperature to rise, while cold stress occurs when the body’s core temperature drops too low.

To prevent heat or cold stress, it is essential to ensure that workers wear appropriate protective clothing and that the space is adequately ventilated. Here are some steps that can be taken to prevent heat or cold stress in confined spaces:

- Identify the potential for extreme temperatures in the confined space and assess the risk to workers.

- Ensure workers are provided with appropriate personal protective equipment (PPE), such as heat-resistant clothing, gloves, face shields, or insulated clothing and gloves for cold temperatures.

- Train workers on the signs and symptoms of heat and cold stress and how to prevent them.

- Monitor workers for signs of heat or cold stress, such as fatigue, headache, dizziness, or confusion.

- Provide adequate ventilation in the confined space to help regulate the temperature and reduce the risk of heat or cold stress.

- Monitor the temperature and humidity levels in the confined space and implement measures to control the temperature and humidity, such as using fans or heaters.

- Provide workers access to cool or warm water, and encourage them to take frequent breaks to prevent dehydration.

- Implement safe work practices and procedures, such as scheduling work during cooler times, limiting workers’ time in the confined space, and using a buddy system.

- Regularly inspect and maintain equipment, such as ventilation systems and heating or cooling devices, to ensure they are in good working condition.

- Provide adequate warning signs and labels to indicate the potential for extreme temperatures in the confined space.

Extreme temperatures can be a significant hazard in confined spaces, and it is essential to take appropriate safety measures to prevent heat or cold stress. Providing workers with appropriate PPE, adequate ventilation, and access to water, implementing safe work practices and procedures, and regularly inspecting and maintaining equipment can significantly reduce the risk of heat or cold stress in confined spaces.

9. Drowning Of Workers

Drowning is one of the most severe hazards that workers may face when working in confined spaces. This can occur when there is an increase in the level of liquid or water, such as in tanks or underground chambers. The confined space may fill up with water, which can rapidly rise and overwhelm workers, leading to drowning.

To prevent drowning hazards in confined spaces, there are several precautions that employers and workers should take. For instance, all workers should receive proper training in confined spaces, including understanding the hazards of working in wet or submerged environments. Employers should also provide the appropriate personal protective equipment (PPE), such as life jackets or flotation devices, to workers who work in confined spaces with water or other liquids.

Before entering a confined space, it is crucial to assess the area to identify any potential hazards, including the risk of drowning. Employers should also ensure workers are not alone when working in confined spaces with water or other liquids. They should also have an emergency response plan for incidents or accidents, including drowning.

It is also crucial to continuously monitor the level of liquids in confined spaces. Employers should have a system to ensure that workers are notified immediately of any increase in the liquid level. Workers should be trained to evacuate quickly in such cases and seek immediate medical attention in case of any injuries.

10. Fall Hazards

A fall hazard is a potential danger associated with confined spaces with an open top or an elevated entry point, leading to the risk of falling. Workers can fall from ladders, stairways, or other elevated surfaces, leading to serious injuries or fatalities. Here are some ways to avoid fall hazards in confined spaces:

- Identify all potential fall hazards associated with the confined space and implement appropriate safety measures.

- When working at heights, use a safety harness with a lifeline, and ensure it is properly anchored.

- Install guardrails or barriers around open areas, and ensure they are properly secured.

- Ensure that ladders or stairs used to enter or exit the confined space are secure and stable.

- Always use three points of contact when climbing up or down a ladder or stairs.

- Avoid carrying tools or equipment while climbing up or down a ladder or stairs.

- Use non-slip footwear to avoid slipping or tripping.

- Ensure that lighting is adequate to help workers see potential hazards.

- Never jump or step across gaps or openings.

- Train workers on how to use fall protection equipment and emergency procedures.

- Conduct regular inspections of equipment and structures to ensure their safety.

- Develop a rescue plan that includes procedures for rescuing workers who may have fallen or become trapped in a confined space.

11. Biological Hazards

Biological hazards are a potential risk in confined spaces, as they can harbor bacteria, viruses, and molds that can cause illness or disease in workers. These hazards can be present in confined spaces such as wastewater treatment facilities, animal waste storage areas, or other areas with high organic matter levels. To prevent exposure to biological hazards, it is essential to wear appropriate personal protective equipment (PPE) and ensure that the space is adequately ventilated.

Here are some steps that can be taken to prevent exposure to biological hazards in confined spaces:

- Identify the potential for biological hazards in the confined space and assess the risk to workers.

- Develop a written plan for working in confined spaces with biological hazards, including entry, exit, and emergency response procedures.

- Train workers on the potential risks associated with working in confined spaces with biological hazards and the proper use of PPE and safe work practices.

- Provide workers with appropriate PPE, such as gloves, respirators, and other protective gear.

- Ensure that the confined space is adequately ventilated to prevent the buildup of airborne contaminants.

- Monitor the air quality in the confined space to detect any biological hazards and take corrective action as necessary.

- Use proper cleaning and decontamination procedures to prevent the spread of biological hazards.

- Implement safe work practices and procedures, such as washing hands and other exposed skin before and after work and avoiding touching the face or mouth.

- Regularly inspect and maintain ventilation systems and other equipment to ensure they are in good working condition.

- Provide adequate warning signs and labels to indicate potential biological hazards in the confined space.

Biological hazards can be a potential risk in confined spaces, and it is essential to take appropriate safety measures to prevent exposure. Providing appropriate PPE, ensuring adequate ventilation, implementing safe work practices and procedures, and regularly inspecting and maintaining equipment can significantly reduce the risk of exposure to biological hazards in confined spaces.

12. Poor Visibility

Poor visibility is a common hazard that can lead to accidents and injuries in confined spaces. In many cases, these spaces are poorly lit, making it difficult for workers to see what they’re doing and where they’re going. This can be particularly dangerous when working with hazardous materials or when falling or tripping is risky.

To reduce the risk of accidents due to poor visibility, it is essential to ensure that the confined space is adequately lit. This can be achieved by using portable lighting or installing permanent lighting fixtures. The lighting should be bright enough to allow workers to see clearly and should be placed in areas where it will not create shadows or glare.

In addition to proper lighting, workers should wear reflective clothing to increase visibility. This is particularly important when working in areas with heavy machinery or vehicles that may not be able to see workers in low-light conditions. Reflective clothing can help to make workers more visible and reduce the risk of accidents.

It’s important to note that workers should never rely solely on their personal protective equipment (PPE) for visibility in a confined space. While reflective clothing is essential, it should be used with other safety measures, such as adequate lighting, hazard identification, and control measures.

Poor visibility is a significant hazard in confined spaces, leading to accidents and injuries. Proper lighting and reflective clothing can help to reduce the risk of accidents and create a safer working environment for workers.

13. Psychological Hazards

One of the psychological hazards associated with confined spaces is the potential for workers to experience anxiety or panic attacks. The confined nature of these spaces can lead to feelings of claustrophobia, which is a fear of enclosed spaces. This fear can be triggered by the lack of light, ventilation, or space and the presence of hazardous materials or machinery.

To prevent psychological hazards in confined spaces, it’s important to properly train workers. This training should cover the risks associated with confined spaces and the procedures for working safely in these environments. Workers should also receive the necessary equipment and support to manage their anxiety or stress levels. For example, workers may be provided with breathing exercises or relaxation techniques to help them stay calm in stressful situations.

Additionally, it’s important to ensure that workers are properly supervised while working in confined spaces. This can help identify signs of stress or anxiety early on so that appropriate action can be taken to prevent more serious issues. Regular breaks and task rotation can also help reduce the psychological stress of working in confined spaces.

Overall, it’s important to recognize the psychological hazards associated with confined spaces and to take steps to prevent them. Proper training, equipment, support, effective supervision, and work organization can help ensure workers’ safety and well-being in these environments.

Conclusion

Working in confined spaces presents various hazards that can be life-threatening. However, these risks can be minimized with proper planning, training, and safety procedures. The twelve common confined space hazards we discussed include lack of oxygen, toxic atmospheres, fire and explosion, engulfment, electrical hazards, physical hazards, extreme temperatures, biological hazards, poor visibility, psychological hazards, falling objects, and noise.

To prevent these hazards, it is essential to follow established safety procedures, such as testing the air quality, ensuring proper ventilation, providing appropriate personal protective equipment, and establishing lockout/tagout procedures. Workers should also receive proper training on recognizing and responding to these hazards.

Understanding that confined space hazards can change quickly is crucial, so regular monitoring and hazard assessments are necessary. Employers must ensure that all workers know the potential hazards and have the necessary training and equipment to work safely in confined spaces.

Ultimately, by following the appropriate safety measures and procedures, workers can safely and effectively work in confined spaces while avoiding injury or harm.