Electricity is one of the most essential forms of energy used in our daily lives. While it makes life easier, it also poses a significant risk of electrical hazards. Electrical accidents can result in severe injuries, including burns, electrocution, and even death. Electrical safety is crucial to prevent accidents and ensure electrical systems operate efficiently and effectively. To minimize the risk of electrical hazards, it’s important to follow the proper safety rules and precautions.

In this blog, we will discuss ten essential rules for electrical safety, including the hazards associated with electrical systems and the control measures that can be taken to prevent accidents. Whether you’re an electrical worker, homeowner, or business owner, these rules are critical to protecting yourself and others from electrical hazards. By following these guidelines, you can ensure that you operate electrical systems safely and effectively and prevent electrical accidents that could cause serious harm.

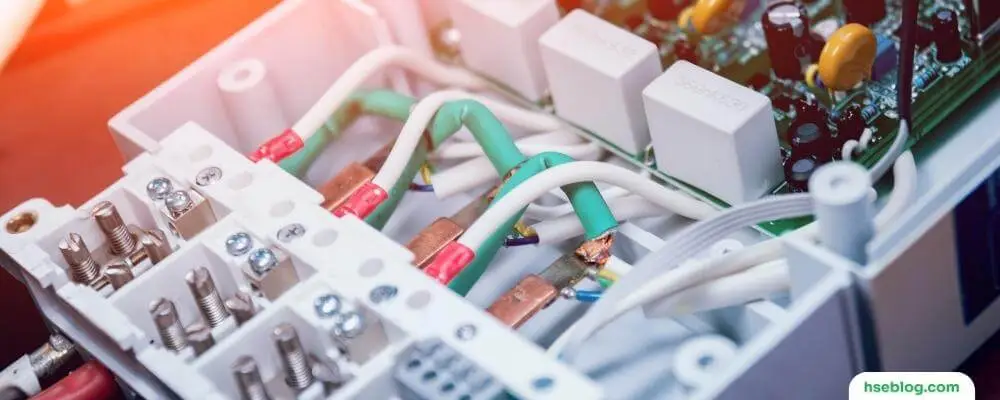

Electrical work, from the largest to the smallest installation, must be carried out by people known to be competent to undertake such work. New installations always require expert advice at all appropriate levels to cover design aspects of the system and those of its associated equipment. Electrical systems and equipment must be properly selected, installed, used, and maintained.

In the UK, approximately 8% of all fatalities at work are caused by electric shock. Over the last few years, there have been 1,000 electrical accidents each year, and about 25 people die of their injuries annually. Most fatalities occur in the agriculture, extractive, and utility supply and service industries, whereas most major accidents happen in the manufacturing, construction, and service industries.

Only voltages up to and including mains voltage (220/240V) and the three principal electrical hazards – electric shock, electric burns, and electrical fires and explosions – are detailed in this chapter.

Electrical Safety Regulations

Regulations aim to ensure the safety of people in the workplace and the public by providing a framework of minimum standards for the design, selection, installation, operation, and maintenance of electrical equipment. The Regulations also require that those who carry out electrical work are competent.

The Electricity at Work Regulations 1989 (EAWR) state that:

- All systems shall be of such construction as to prevent danger so far as is reasonably practicable.

- Systems shall be maintained to prevent danger so far as is reasonably practicable.

- Equipment shall be selected and installed considering the conditions under which it is used and all relevant circumstances, including the character and quantity of electrical energy available.

- Equipment shall be used only by persons properly instructed in its use.

- Equipment shall be maintained in a safe condition, and the maintenance carried out by persons who are competent to do so.

The Electricity at Work Regulations 1989 (EAWR) places a duty on employers to ensure, so far as is reasonably practicable, the safety of their employees and other persons who may be affected by their work.

Employers must also ensure that employees are properly instructed in the safe systems of work to be adopted and are provided with any necessary information, training, and supervision.

The Regulations apply to all electrical systems and equipment used at work, whether portable or fixed and include anything connected to the mains electricity supply. They do not, however, apply to low-voltage electrical equipment used in domestic premises. The term ‘electrical work’ is defined in the Regulations as:

- The installation of an electrical system or part of an electrical system.

- The addition, alteration or repair of an electrical system or part of an electrical system.

- The disconnection or removal of an electrical system or part of an electrical system.

All work carried out on any electrical equipment must be done by a competent person. A competent person has the necessary skills, knowledge, and experience to carry out the work safely and to the required standard.

Importance Of Electrical Safety

Electrical safety is of utmost importance as it plays a critical role in ensuring the safety and well-being of individuals and the community. Electrical hazards can lead to severe injuries and even death, prevalent in residential and commercial settings. According to the Electrical Safety Foundation International (ESFI), electrical hazards are responsible for an average of 400 electrocutions, 4,400 injuries, and over $1 billion in property damage annually in the United States alone.

Following electrical safety guidelines and procedures can prevent accidents, which helps protect people, property, and the environment. Electrical safety measures also help minimize the risk of fires, explosions, and other potential hazards resulting from electrical malfunctions.

In addition, electrical safety regulations and standards ensure that electrical systems are designed, installed, and maintained according to safety standards and that electrical workers are properly trained to work safely with electricity. Compliance with these standards ensures that electrical systems are reliable, efficient, and safe for everyone who uses them.

Overall, electrical safety is essential for protecting individuals, property, and the environment from the dangers of electrical hazards. Understanding and following electrical safety guidelines and procedures is important to prevent accidents and promote safety in all aspects of electrical use.

10 Electrical Safety Hazards

Here are the top ten electrical safety hazards that you should be aware of:

- Electrical Shock: The most common electrical safety hazard, an electrical shock, occurs when the human body comes into contact with a live electrical current. This can cause burns, muscle contractions, and even cardiac arrest.

- Arc Flash: An arc flash is a sudden and violent release of electrical energy that can occur when an electrical system has a fault or short circuit. This can cause severe burns, hearing damage, and even blindness.

- Electrical Burns: Electrical burns can occur when the skin comes into contact with an electrical current. These burns can be severe and can cause permanent scarring and tissue damage.

- Electrical Fires: Electrical fires can occur when an electrical system has an overload or short circuit. These fires can spread quickly and can cause significant damage to property and people.

- Electrocution: Electrocution occurs when a person is exposed to a high-voltage electrical current. This can cause fatal injuries, including cardiac arrest and severe burns.

- Improper Grounding: Improper grounding occurs when electrical systems are not properly connected to the earth, leading to electrical shock, fires, and other hazards.

- Overloaded Circuits: Overloaded circuits occur when too many electrical devices are connected to a single circuit, causing it to overheat and potentially fire.

- Electrical Explosions: Electrical explosions can occur when there is a fault in an electrical system, causing an explosion or fire. These explosions can be particularly dangerous in areas with flammable materials.

- High Voltage: High-voltage electrical systems pose a significant risk to workers and can cause serious injuries, including burns, electrocution, and cardiac arrest.

- Damaged Electrical Cords: Damaged electrical cords can pose a serious safety hazard as they can cause electrical shock, fires, and explosions. It is important to regularly inspect cords for damage and replace them if necessary.

It’s important to be aware of these electrical safety hazards and take appropriate measures to prevent them. Always follow safety guidelines, use certified equipment, inspect equipment regularly, and seek professional help when needed.

10 Electrical Safety Rules You Need To Know

Electrical safety is crucial to prevent accidents and injuries caused by electrical shock, electrocution, or electrical fires. Here are some essential electrical safety rules you should follow:

1. Familiarize Yourself with the Basics

Understanding the fundamentals of electricity and electrical safety is crucial before attempting any electrical work or repairs. This knowledge will help you recognize potential hazards and avoid dangerous situations. Here are some key concepts to grasp:

- Electrical current: The flow of electrons through a conductor, such as a wire. It is measured in amperes (A).

- Voltage: The force that pushes the electrical current through a conductor, measured in volts (V).

- Resistance: The opposition to the flow of electrical current within a conductor, measured in ohms (Ω).

- Circuit: A closed-loop through which electrical current flows.

- Grounding: Connecting an electrical system or appliance to the earth to prevent hazardous electrical buildup.

- Fuses and circuit breakers: Protective devices designed to interrupt the flow of electricity when an overload or short circuit occurs.

- Insulation: Non-conductive materials, such as plastic or rubber, that cover electrical wires and components to prevent direct contact with live parts and minimize the risk of electric shock.

- Electric shock: The physiological reaction or injury caused by the flow of electrical current through the body.

By familiarizing yourself with these concepts and terms, you can better understand how electricity works and how to handle it safely. This foundational knowledge will also help you identify and assess electrical hazards, allowing you to take appropriate precautions when working with or around electrical systems and devices.

2. Understand Your Equipment

Gaining a thorough understanding of your equipment is essential for electrical safety. This rule can be broken down into two aspects:

Know how your equipment operates

Familiarize yourself with the functionality and safety features of the electrical devices or appliances you will be working with. Ensure to read and follow the manufacturer’s instructions, guidelines, and safety warnings in the user manuals. If you are unsure about any aspect of the equipment’s operation, consult the manual or seek help from a qualified professional.

Ensure compatibility of equipment.

Before using electrical devices or appliances, ensure they are compatible with each other and the electrical system they are connected to. This includes:

- Voltage compatibility: Verify that the voltage ratings of your equipment match the voltage of the power source they will be connected to. Connecting devices designed for different voltages can result in damage, malfunction, or dangerous electrical hazards.

- Wattage and current capacity: Check the power requirements of all devices you intend to plug into an extension cord, power strip, or outlet. Ensure the combined wattage or current draw does not exceed the capacity of the power source. Overloading can cause overheating, fires, or damage to the devices.

- Plugs and connectors: Use appropriate plugs and connectors for your equipment, and make sure they fit securely in the outlets. Loose connections can lead to arcing, which can cause fires or damage the equipment.

By understanding your equipment and ensuring compatibility, you minimize the risk of electrical accidents and help protect yourself and others from potential hazards.

3. Inspect Before You Use

Inspecting electrical equipment thoroughly before use is crucial in ensuring safety. Damaged or malfunctioning devices can lead to accidents, electric shocks, or fires. Follow these guidelines when inspecting electrical equipment:

- Check cords and plugs: Look for frayed, cracked, or damaged cords, as well as bent or broken prongs on the plugs. Examine the insulation for wear, cracks, or missing sections.

- Inspect power outlets: Ensure that outlets are securely fastened and not loose, which could lead to arcing or poor connections. Check for any signs of burning, discolouration, or damage, which could indicate a problem with the outlet or the connected devices.

- Examine the equipment: Look for any visible damage or signs of wear on the device, such as cracked or broken casings, loose parts, or missing screws. Ensure that any ventilation openings are clean and debris-free to prevent overheating.

- Test safety features: Verify that safety features, such as ground fault circuit interrupters (GFCIs) or residual current devices (RCDs), are functioning correctly by using the “test” button provided on the devices.

Do not use the equipment if you discover any damage or problems during your inspection. Replace or repair it with a qualified professional before using it again. Inspecting your electrical equipment can significantly reduce the risk of accidents and ensure a safer environment.

4. Use the Right Tools for the Job

Using appropriate tools and safety equipment for electrical work is essential for your safety and the task’s success. The right tools can help you perform the job effectively and minimize the risk of accidents. Follow these guidelines when selecting and using tools for electrical work:

- Choose insulated tools: Use tools with insulated handles, specifically designed for electrical work, to protect against electric shock. These tools often have handles made of non-conductive materials, such as rubber or plastic, and are marked with a voltage rating.

- Select the correct size and type: Choose the right tool for your task. Using the wrong size or type of tool can lead to accidents or damage to the equipment. For example, use wire strippers for stripping wires and the correct screwdriver size for the screws you’re working with.

- Keep tools in good condition: Regularly inspect and maintain them to ensure they remain in good working order. Damaged tools can increase the risk of accidents or make the job more difficult.

- Use appropriate safety gear: When working with electricity, wear safety gear, such as insulated gloves, safety glasses, and non-conductive footwear, to protect yourself from potential hazards. Remember to always use safety gear in accordance with the manufacturer’s guidelines and specifications.

Using the right tools and safety equipment for electrical tasks can significantly reduce the risk of injury, accidents, and damage to the equipment or devices you’re working on.

5. Be careful with Extension Cords

Using extension cords safely is essential to prevent electrical fires and accidents. Follow these guidelines when using extension cords:

- Choose the right cord: Select an extension cord with the appropriate gauge, length, and capacity for your needs. Ensure it is rated for the intended use, such as indoor or outdoor use, and has the necessary wattage or amperage rating to handle the connected devices.

- Avoid overloading: Do not plug too many devices into an extension cord, which can cause overheating and potentially lead to a fire. Ensure the connected devices’ combined wattage or current draw does not exceed the extension cord’s capacity.

- Unplug correctly: When disconnecting an extension cord, pull on the plug, not the cord or the connected appliance. Pulling on the cord can cause damage to the wires, increasing the risk of fire or electrical shock.

- Keep cords visible: Do not run extension cords under rugs, carpets, or furniture, as this can damage the cord and make it difficult to spot potential problems. Concealed cords can overheat and pose a fire hazard.

- Inspect cords regularly: Check extension cords for any signs of wear or damage before each use. Look for frayed wires, cracked insulation, or bent prongs on the plug. If you find any damage, replace the cord immediately.

- Use temporary solutions: Extension cords should be a temporary solution, not a permanent wiring option. If you rely on extension cords frequently, consider installing additional outlets by a licensed electrician.

Following these guidelines, you can safely use extension cords and minimize the risk of electrical fires and accidents.

6. Do Not Use Substandard Products

Using high-quality, certified electrical products is crucial for ensuring safety and reducing the risk of accidents or fires. Substandard products may not meet safety requirements or be made with inferior materials, increasing potential hazards. Follow these guidelines when selecting electrical products:

- Look for safety certifications: Choose products that have been tested and approved by reputable testing laboratories, such as Underwriters Laboratories (UL), Intertek (ETL), or CSA International (CSA). These organizations evaluate electrical products for safety and compliance with industry standards.

- Be cautious of counterfeit products: Counterfeit electrical products may have fake safety certifications or not meet safety standards. Avoid purchasing counterfeit items, buy from reputable retailers or authorized dealers, and be sceptical of deals that seem too good to be true.

- Check for recalls: Regularly check for product recalls to ensure the electrical products you are using have not been found to pose a safety risk. The U.S. Consumer Product Safety Commission (CPSC) website is a valuable resource for information on recalled products.

- Inspect packaging and labelling: Examine product packaging for clear and accurate labelling, including manufacturer information, safety certifications, and voltage ratings. Products with missing or unclear information may be of poor quality or counterfeit.

By using high-quality, certified electrical products, you can help ensure your safety and the safety of those around you while minimizing the risk of accidents and fires.

7. Do Not Modify Electrical Products

Modifying electrical products can be extremely dangerous and may result in electrical shock, fires, or other accidents. Altering a product can also void its safety certifications, such as UL or ETL approval. Follow these guidelines to avoid modifying electrical products:

- Purchase products that meet your needs: Select electrical products designed for the intended purpose, voltage, and environmental conditions. If you need a different product type, purchase one specifically designed for your needs rather than attempting to modify an existing product.

- Do not modify products: Never modify electrical products by removing safety features, bypassing fuses, or changing their intended use or voltage rating. Such modifications can increase the risk of accidents or damage to the equipment.

- Follow manufacturer instructions: Always follow the manufacturer’s instructions for installing, operating, and maintaining electrical products. If you have any doubts about the appropriate use or installation of a product, seek guidance from a qualified electrician or the manufacturer.

- Be cautious of DIY repairs: Attempting to repair electrical products yourself can be dangerous and may lead to damage or malfunction. Always seek the assistance of a qualified professional for any repairs or maintenance.

By avoiding modifying electrical products, you can help ensure your safety and reduce the risk of accidents or damage to the equipment.

8. Be Wary of Water

Water is a conductor of electricity, and mixing water with electrical equipment can lead to electrical shock or even electrocution. Follow these guidelines to minimize the risk of electrical hazards around water:

- Keep electrical equipment away from water sources: Do not use or store electrical devices or appliances near water sources such as sinks, bathtubs, or pools. Keep cords and plugs away from wet areas.

- Use ground fault circuit interrupters (GFCIs): Install GFCIs in all electrical outlets in wet areas, such as bathrooms, kitchens, and outdoor areas. GFCIs detect changes in electrical current and immediately cut off power to prevent electrical shock.

- Be cautious with portable devices: Do not use portable electrical devices, such as hair dryers or radios, near water sources or in wet areas. If you must use them in these environments, use battery-operated devices or ensure they are properly grounded.

- Protect outdoor equipment: Ensure that all outdoor electrical equipment, such as lights, power tools, and extension cords, are designed for outdoor use and are protected from water and moisture.

- Be aware of damp conditions: In damp or humid environments, be aware of the potential for moisture to affect electrical equipment. Check electrical cords and devices regularly for signs of damage or wear, and ensure they are properly grounded.

Awareness of the risks associated with water and electricity can help prevent electrical accidents and ensure your safety.

9. Install warning signs

Installing warning signs in areas where electrical hazards may be present can help prevent accidents and injuries. Properly placed electrical signs can provide clear guidance and reduce the risk of accidental contact with live systems. Follow these guidelines when installing warning signs:

- Identify potential hazards: Identify areas where electrical hazards may be present, such as electrical rooms, high voltage areas, or places with exposed wiring.

- Use clear and concise language: Use clear and concise language on the warning signs to convey the potential danger. The message should be easy to read and understand.

- Use appropriate graphics: Include them on the warning signs to enhance effectiveness. Graphics can quickly convey a message, especially for non-native language speakers.

- Place signs in prominent locations: Install warning signs in prominent locations, such as near entrances or areas where they are likely to be seen.

- Replace damaged or missing signs: Regularly check the condition of the warning signs and replace any damaged or missing ones.

Installing warning signs in areas with potential electrical hazards can help prevent accidents and promote a safer environment.

10. Use Personal Protective Equipment (PPE)

When working on electrical circuits or equipment, it’s important to use personal protective equipment (PPE) to minimize the risk of electrical shock or injury. Follow these guidelines when using PPE:

- Use insulated rubber gloves: Insulated rubber gloves can protect you from electric shock when working on energized circuits. Ensure the gloves are rated for the voltage of the circuit you are working on, and always inspect them for damage or wear before each use.

- Wear goggles: Goggles can protect your eyes from sparks, debris, and other hazards when working with electrical equipment. Choose goggles with side shields and ensure they fit snugly to your face.

- Use non-conductive footwear: Non-conductive footwear can provide additional protection from electrical shock. Avoid wearing shoes with metal components, such as steel-toed boots, when working on electrical circuits.

- Wear appropriate clothing: Wear clothing that is fitted and made of non-conductive materials to minimize the risk of contact with energized circuits. Remove any metal jewellery, such as watches or bracelets, before working on electrical equipment.

- Follow manufacturer instructions: Always follow the manufacturer’s instructions for using PPE, including proper cleaning and maintaining the equipment.

Using appropriate PPE can help protect yourself from electrical hazards and minimize the risk of injury or electric shock.

Conclusion

Electrical safety is essential to minimize the risk of accidents, injuries, and property damage. The 10 rules for electrical safety outlined in this article provide guidelines for understanding the basics of electricity, selecting appropriate equipment, inspecting equipment, avoiding overloading extension cords, using certified electrical products, avoiding modifying electrical equipment, being wary of water, installing warning signs, and using personal protective equipment.

By following these rules and taking appropriate precautions, you can help ensure your safety and the safety of those around you when working with electrical equipment and circuits. Always consult a qualified professional if you have any doubts or questions regarding electrical safety.