As an Industrial Hygienist and Environmental Specialist, I was auditing a mid-sized chemical processing plant in the Middle East when my portable multi-gas detector started alarming near the bulk storage tanks. A localized temperature inversion had trapped low-lying fugitive vapor emissions, creating a toxic micro-environment that the local workforce was completely unaware of. This was not a catastrophic explosion making headlines; it was a slow, invisible, and highly dangerous environmental hazard actively compromising the respiratory health of everyone on the night shift.

Workplace environmental hazards are rarely as dramatic as a falling crane, but they account for the vast majority of long-term occupational illnesses, regulatory fines, and impacts on surrounding communities. In this article, I will break down the seven most common environmental hazards found across industrial sites, from airborne contaminants and noise pollution to biological risks and thermal stress. Understanding these hazards is not just about passing an ISO 14001 or OSHA audit; it is about recognizing the invisible threats that degrade worker health and ensuring everyone leaves the site in the same condition they arrived.

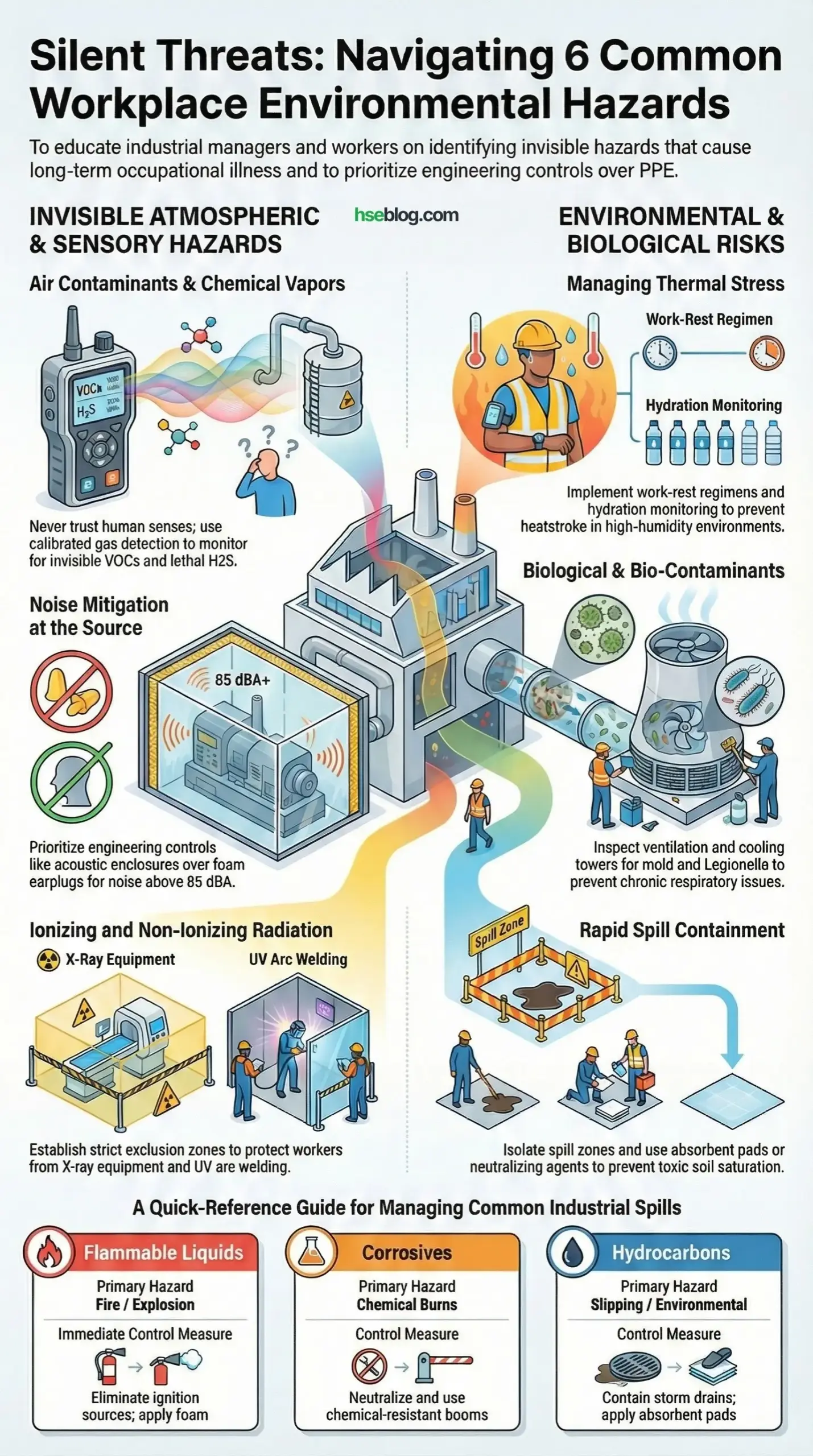

1. Airborne Contaminants and Chemical Vapors

In heavy industries and manufacturing, the air workers breathe is often the most significant vector for environmental hazards. Whether it is crystalline silica on a construction site or volatile organic compounds (VOCs) in a paint shop, airborne contaminants pose immediate and long-term systemic risks.

Industrial hygiene monitoring often reveals that natural ventilation is rarely enough to protect workers. I have shut down entire sandblasting operations because local exhaust ventilation (LEV) systems were bypassed to save time, exposing the crew to hazardous particulates. Under the hierarchy of controls, ventilation must always take precedence over forcing workers into respirators.

Common airborne hazards I encounter include:

- Welding fumes containing hexavalent chromium and heavy metals

- Fugitive emissions from unsealed chemical valves or flanges

- Aerosolized oil mists in metal machining operations

- Dust and particulate matter (PM2.5 and PM10) from aggregate processing

Field Note: Never trust human senses to detect hazardous atmospheres. Hydrogen sulfide (H2S), for example, causes olfactory fatigue, meaning you lose the ability to smell it just as concentrations reach lethal levels. Always rely on calibrated gas detection.

2. Hazardous Noise Pollution

Noise-induced hearing loss (NIHL) is the most pervasive, yet preventable, occupational disease I encounter during site inspections. Industrial noise does not just damage hearing; it creates a secondary environmental hazard by masking critical safety alarms and reducing situational awareness.

The threshold for mandatory hearing protection under OSHA 1910.95 is 85 decibels (dBA) over an 8-hour time-weighted average (TWA). However, I have seen too many supervisors rely solely on foam earplugs rather than addressing the noise source. Hearing conservation programs must prioritize engineering controls before relying on personal protective equipment (PPE).

Engineering Out the Noise

Real noise reduction requires isolation. In power generation plants, we encase heavy turbines in acoustic enclosures to dampen the decibel output at the source. If the hazard cannot be enclosed, we must rotate workers out of the high-noise zone to limit their time-weighted exposure.

3. Thermal Stress and Extreme Temperatures

Working in extreme heat or freezing environments physically degrades the human body’s ability to regulate its internal temperature. Heat stress is particularly deadly on megaprojects and in metal processing, leading to heat exhaustion and fatal heatstroke if ignored.

I have investigated near-misses where crane operators nearly passed out in un-airconditioned cabs during the peak summer months. Environmental temperature hazards require strict work-rest regimens, acclimatization protocols, and constant hydration monitoring.

Key thermal stressors include:

- High ambient temperatures combined with high humidity (preventing sweat evaporation)

- Radiant heat from furnaces, boilers, or molten metal operations

- Cold stress and hypothermia in refrigerated warehousing or winter construction

- Direct sun exposure leading to severe sunburns and UV radiation risk

4. Biological Hazards and Bio-Contaminants

Biological environmental hazards are often overlooked in standard industrial settings until a localized outbreak occurs. These hazards include viruses, bacteria, fungi, and other living organisms that can cause acute or chronic infections among the workforce.

During an environmental assessment of an underground tunneling project, we discovered severe black mold (Stachybotrys) growing in damp, poorly maintained ventilation shafts. Workers were attributing their chronic coughs to concrete dust when, in reality, they were suffering from fungal exposure.

Common Bio-Hazard Sources

- Stagnant water in cooling towers leading to Legionella outbreaks

- Mold and fungal spores in poorly ventilated, high-humidity work areas

- Bloodborne pathogens in healthcare or emergency response settings

- Bacterial infections from contact with raw sewage or industrial wastewater

5. Chemical Spills and Soil Contamination

Loss of containment is a massive environmental hazard that directly impacts the workplace floor and the underlying soil and groundwater. A spill is not just an environmental compliance failure; it creates immediate slip hazards and toxic exposure zones for nearby workers.

I once managed the remediation of a site where years of “minor” hydraulic fluid leaks from heavy mobile equipment had saturated the ground. Management ignored the drips until we had to excavate tons of soil and treat it as hazardous waste, costing the project millions and halting operations.

| Spill Type | Primary Hazard | Immediate Control Measure |

| Flammable Liquids (Gasoline/Solvents) | Fire / Explosion | Eliminate ignition sources, apply foam blanket. |

| Corrosives (Acids/Bases) | Chemical Burns / Toxic Vapor | Neutralize, isolate area, use chemical-resistant booms. |

| Heavy Oils / Hydrocarbons | Slipping / Environmental Damage | Contain storm drains, apply absorbent pads. |

6. Radiation (Ionizing and Non-Ionizing)

Radiation is an invisible environmental hazard present in more workplaces than most people realize, from medical facilities to heavy construction sites using industrial radiography. Exposure can lead to severe tissue damage, burns, and long-term carcinogenic effects.

On a pipeline project, I had to intervene and stop work when a subcontractor’s non-destructive testing (NDT) crew failed to establish a proper radiation exclusion zone. Welders were working directly behind the barricade tape, absorbing scatter radiation from X-ray equipment.

Common radiation hazards include:

- Ionizing radiation from X-ray machines and radioactive isotopes used in welding inspection

- Ultraviolet (UV) radiation from arc welding (welder’s flash) and direct sunlight

- Infrared radiation from hot work processes like glass blowing and metal smelting

- Radiofrequency (RF) energy around high-powered telecommunications antennas

7. Poor Illumination and Visual Hazards

Inadequate or improper lighting is an environmental hazard that directly contributes to slips, trips, falls, and ergonomic strain. Whether it is insufficient lux levels in a warehouse or blinding glare on a production line, the visual environment dictates how safely a job can be performed.

During a night-shift audit at a logistics terminal, I found forklift operators working in near-total darkness because half the floodlights were burnt out. Management dismissed it as a maintenance delay, but I classified it as an immediate threat to life and halted operations until temporary lighting towers were mobilized.

Pro Tip: Always measure workplace lighting in “lux” using a calibrated light meter. Relying on visual estimates is subjective and will not stand up during an incident investigation if a worker falls in a dimly lit area.

Conclusion

Environmental hazards are often silent and cumulative, making them easy for operations managers to ignore in favor of immediate production goals. Identifying these seven hazards—airborne contaminants, noise, thermal stress, bio-hazards, spills, radiation, and poor lighting—is the foundation of any robust industrial hygiene and environmental management system.

As safety leaders, we must remember that a worker’s health does not end at the factory gate. Compromising on environmental controls to save time or money is an ethical failure. Human life and long-term health will always outweigh production metrics and compliance check-boxes.