In our day-to-day lives, we encounter various circumstances that pose potential harm or danger – we call these hazards. They exist in numerous forms and settings, extending from our personal homes to public spaces and significantly in our workplaces. Understanding the different types of hazards and how to control them is key to maintaining our safety and well-being.

This blog delves into the complex hazards world, highlighting their types and providing real-world examples. We will explore biological hazards like bacteria and viruses, psychological hazards including stress and workplace bullying, and public health hazards often caused by poor access to clean water. More importantly, we will provide you with an understanding of effective control measures that can be put in place to mitigate these risks. This knowledge will enable you to recognize potential dangers and make informed decisions to minimize or prevent harm. Join us as we navigate this critical aspect of everyday life, setting the groundwork for a safer environment.

What is Hazard?

A hazard can be anything that can cause harm or damage to people, property, or the environment. It is important to note that a hazard does not necessarily have to be physical; it can also be chemical, biological, or psychological. Hazardous substances and conditions can exist in both natural and man-made environments.

What is Risk?

Risk is the likelihood that a hazard will cause harm or damage. It is important to note that not all hazards will result in an accident or incident; the level of risk is determined by the severity of the potential harm or damage and the likelihood that it will occur.

Types Of Hazards And Examples

There are four main types of hazards:

- Physical hazards

- Chemical hazards

- Biological hazards

- Psychological hazards

- Public Health Hazards

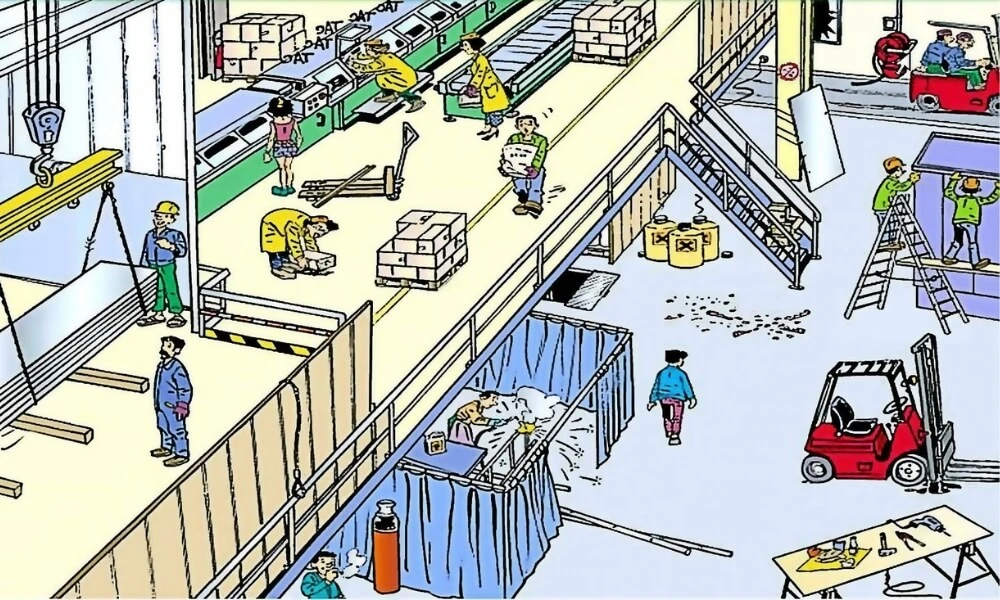

1. Physical Hazards & Control Measures

Physical hazards refer to the dangers a substance or object poses due to its physical properties. These hazards can be either visible or invisible or naturally occurring or man-made.

Many different types of physical hazards can be present in the workplace. Some of the most common include:

- Falls: Falls from heights are among the most common causes of severe injury and death in the workplace. Workers should always use proper safety equipment and follow safe work practices when working at heights.

- Slips, trips, and falls: Slips, trips, and falls are also common causes of injuries in the workplace. Workers should be aware of potential hazards in their work area and take precautions to avoid them.

- Exposure to harmful substances: Workers may be exposed to harmful substances such as chemicals, dust, or fumes while working. Following safe work practices and using proper personal protective equipment is essential to avoid exposure.

- Ergonomic hazards can cause musculoskeletal disorders such as carpal tunnel syndrome or back injuries. Workers should be aware of potential ergonomic hazards in their work environment and take steps to prevent them.

- Noise: Exposure to loud noise can cause hearing loss. Workers should use hearing protection when working in noisy environments.

- Heat and cold: Exposure to extreme temperatures can cause heat or cold stress. Workers should take precautions to avoid exposure to extreme temperatures.

- Lighting: Poor lighting can cause eye strain and other vision problems. Workers should have adequate lighting in their work area.

- Electricity: Exposure to electrical hazards can cause shock, burns, or even death. Workers should be aware of potential electrical hazards in their work environment and take steps to avoid them.

- Fire is one of the most dangerous physical hazards because it can spread quickly and cause extensive damage. If you are in an area where a fire is burning, staying calm and evacuating immediately is essential. Do not try to fight the fire yourself; instead, call 911 and let the professionals handle it.

- Floods: Floods are another major physical hazard that can occur suddenly and without warning. If you live in an area prone to flooding, planning how you will evacuate if a flood occurs is essential. Do not try to drive through floodwaters; seek higher ground and wait for help.

- Earthquakes are another type of physical hazard that can be very dangerous. If you are in an area prone to earthquakes, knowing what to do during one is essential. Drop to the ground, cover your head, and hold on to something sturdy until the shaking stops. Then, evacuate the area immediately and do not re-enter until it has been declared safe by authorities.

- Hurricanes are another type of physical hazard that can cause significant damage. If you live in an area prone to hurricanes, it is important to have a plan for how you will evacuate if one does occur. Do not try to ride out the storm; seek shelter and wait for help.

Physical hazards are present in many workplaces. Workers need to be aware of the potential hazards and take steps to avoid them.

2. Chemical Hazards & Control Measures

Many different types of chemical hazards can be present in the workplace. Some of these hazards are more common than others, and others can be more dangerous. It is important to be aware of all the different types of chemical hazards that could be present in your workplace so that you can take steps to protect yourself and your coworkers.

Here are the most common types of chemical hazards that you might encounter in the workplace:

1. Asbestos

Asbestos is a material that can cause lung cancer and other health problems. It is found in some construction materials, such as insulation, and can be released into the air when these materials are disturbed. Asbestos exposure is a serious health hazard, and it is important to take steps to avoid it. You should see a doctor immediately if you suspect you have been exposed to asbestos.

2. Lead

Lead is a heavy metal that can damage the brain, kidneys, and nervous system. Exposure to lead can cause learning and behavior problems and even death. There is no safe level of lead exposure, so it is important to avoid exposure.

Lead is found in many products, including paint, plumbing pipes, and even some types of food. Lead exposure is most common in children, who can be exposed by eating lead-contaminated dust or soil. Adults can also be exposed to lead through work or hobbies that involve lead, such as soldering or working with lead-based paint.

3. Acids and Bases

Acids and bases can be extremely dangerous chemicals. They can cause burns, irritation, and corrosion. If you come into contact with an acid or base, it is important to seek medical attention immediately.

Acids and bases are often used in industrial and manufacturing settings. If you work with these chemicals, taking precautions to protect yourself is important. Wear protective clothing, including gloves and a face mask. Ensure you have access to an emergency eyewash station in case of accidental contact.

4. Flammable Liquids

Flammable liquids are another common type of chemical hazard. These liquids can easily catch fire and can be very dangerous to work with. If you come into contact with a flammable liquid, it is important to seek medical attention immediately.

5. Toxic Gases

Toxic gases can be extremely dangerous. They can cause respiratory problems, irritation, and even death. It is important to know how to safely handle and store toxic gases.

Toxic gases should always be stored in a well-ventilated area. If possible, they should be kept in a specialized storage container. Always wear protective clothing when handling toxic gases. This includes gloves, a mask, and eye protection. If you are working with a large volume of gas, have an emergency plan in case of a leak.

5. Corrosive Chemicals

Corrosive chemicals can cause burns, irritation, and corrosion. Corrosives are found in many common household products, such as drain and oven cleaners. Inhalation of corrosive fumes can also be dangerous. If you come into contact with a corrosive substance, immediately rinse the affected area with cool water for at least 15 minutes. If you have any questions about the safety of a product, always consult the product label or manufacturer.

6. Oxidizing Agents

Some oxidizing agents are so reactive that they can cause fires or explosions. Others may be corrosive, eating away at skin or other tissues. Some oxidizing agents are poisonous if ingested.

Overall, it is important to handle all oxidizing agents with care. If you come in contact with an oxidizing agent, wash the area thoroughly with soap and water. If you are exposed to a large amount of an oxidizing agent or if you experience any adverse effects, seek medical attention immediately.

7. Toxic Metals

There are a variety of ways that toxic metals can enter the body. Inhaling them can cause respiratory problems, while skin contact can lead to irritation or burns. Ingested, they can cause serious gastrointestinal issues. In some cases, exposure to these substances can be fatal.

Identifying toxic metals is often difficult, as they may not be immediately obvious. However, some common signs of exposure include skin irritations, difficulty breathing, and gastrointestinal distress. If you believe you have been exposed to a toxic metal, it is important to seek medical attention immediately.

8. Flammable Solids

Flammable solids are another common type of chemical hazard. These solids can easily catch fire and can be very dangerous to work with. Flammable solids can include things like dust, powders, and chips. They can be made from various materials, including metals, plastics, and chemicals. When these materials are heated, they can catch fire and burn quickly. This can be a serious hazard in the workplace, and it is important to take precautions to avoid it.

There are a few things that you can do to prevent flammable solids from catching fire. First, you should always keep them away from heat sources. This includes things like open flames, heaters, and hot surfaces. Second, you should store them in a cool, dry place. This will help to prevent them from catching fire. Finally, you should always wear protective clothing when working with flammable solids. This includes things like gloves, goggles, and a face mask.

9. Toxic Liquids

Toxic liquids can be extremely dangerous. They can cause respiratory problems, irritation, and even death. If you come into contact with a toxic liquid, it is important to seek medical attention immediately.

10. Flammable liquids

Flammable liquids are another common type of chemical hazard. These liquids can easily catch fire and can be very dangerous to work with. If you come into contact with a flammable liquid, it is important to seek medical attention immediately.

11. Radioactive Materials

Exposure to radiation can cause several health effects, ranging from minor skin irritation to death. The severity of the health effects depends on the amount of radiation exposure and exposure time. Even brief exposures to high levels of radiation can cause serious health effects.

12. Mercury

Mercury is a heavy metal that is poisonous to humans. It can damage the brain, kidneys, and lungs. Mercury exposure can occur through contact with mercury-containing products, such as Thermometers, or from eating fish that contain mercury. Pregnant women and young children are particularly at risk for health effects from mercury exposure. Mercury can also be released into the environment from coal-fired power plants and other sources.

If you work with any of these chemicals, taking precautions to protect yourself is important. Be sure to read all warning labels carefully and follow all safety instructions. If you have any questions about a particular chemical, ask your supervisor or safety officer for more information. Remember, safety comes first!

Many different types of chemical hazards can be present in the workplace. Some of these hazards are more common than others, and others can be more dangerous. It is important to be aware of all the different types of chemical hazards that could be present in your workplace so that you can take steps to protect yourself and your coworkers.

3. Biological Hazards & Control Measures

Biological hazards can cause harm or damage to people, property, or the environment due to exposure to a biological agent. Examples of biological hazards include but are not limited to:

1. Bacteria

When it comes to the workplace, one of the most common hazards is bacteria. Bacteria are tiny, single-celled organisms that can cause disease. While some bacteria are essential for our health, others can make us sick.

Bacteria can enter our bodies through cuts or open wounds and inhale through our nose and mouth. Once inside our bodies, bacteria can multiply and cause illness.

Symptoms of bacterial infections vary depending on the type of bacteria but can include fever, diarrhea, vomiting, and abdominal pain. In severe cases, bacterial infections can lead to death.

2. Fungi

Fungi is a type of microorganism that can cause infections in humans. These infections can range from mild to life-threatening. Fungi can be found in many environments, including soil, water, and plants. Some fungi are even capable of causing disease in healthy people.

Fungal infections can be difficult to treat because the fungi can live inside the human body and are not always destroyed by antibiotics. In some cases, surgery may be required to remove the infected tissue. People with weakened immune systems are at a higher risk of developing fungal infections.

If you think you may have a fungal infection, it is essential to see a doctor to get the proper treatment. Fungal infections can be severe and even life-threatening if not treated promptly.

3. Viruses

Viruses are tiny infectious particles that can replicate inside the cells of living organisms. Viruses can cause various human diseases, from the common cold to more serious illnesses like AIDS. Most viruses are harmless, but some can be deadly. Viral infections have no cure, but treatments are available for some viruses, such as HIV and influenza.

Viruses are classified into two main groups: DNA viruses and RNA viruses. DNA viruses contain genetic material made of deoxyribonucleic acid (DNA). RNA viruses contain genetic material made of ribonucleic acid (RNA).

4. Protozoa

Protozoa are a serious biological hazard. They are responsible for causing diseases such as malaria, amoebiasis, and giardiasis. Protozoa can also contaminate food and water supplies, leading to gastrointestinal illnesses outbreaks. In some cases, protozoa can even be deadly.

There are a few things that you can do to protect yourself from protozoa. First, make sure that you cook your food properly. Protozoa can often be found in contaminated water, so it’s important to boil or filter your water before drinking it. You should also avoid contact with contaminated soil or water. If you do come into contact with contaminated materials, be sure to wash your hands thoroughly. Finally, if you are traveling to an area where protozoa are common, take precautions against mosquito bites, as mosquitoes can transmit some protozoa.

Following these simple tips can help protect yourself from the dangers of protozoa. Remember, however, that protozoa can be a serious threat, so it’s always best to consult a healthcare provider if you have any concerns.

5. Parasites

There are many different types of parasites, and they can be found in various environments. Parasites can cause many diseases, some of which can be deadly.

Most people think parasites only affect animals, but this is not always the case. Many parasites can also infect humans, some of which can be dangerous.

Knowing about these different types of biological hazards can help you avoid them and protect yourself from potential health risks. You must see a doctor immediately if you think you may have been exposed to these hazards.

4. Psychological Hazards & Control Measures

Psychological hazards can cause harm or damage to people, property, or the environment due to exposure to a psychological stressor. Examples of psychological hazards include but are not limited to:

1. Bullying

Bullying in the workplace can lead to many psychological hazards. The first hazard is that it can lead to stress. When you are constantly being bullied, it can take a toll on your mental health and well-being. You may start to feel anxious, depressed, or even suicidal. If you are not careful, bullying can also lead to substance abuse. Bullied people often turn to drugs or alcohol to cope with the pain.

Another psychological hazard of workplace bullying is that it can lead to social isolation. When you are constantly ridiculed and made to feel inferior, you may withdraw from social interactions. You may become scared to speak up or participate in activities because you don’t want to be humiliated. This can lead to loneliness and feeling like you have no one to turn to.

If you or someone you know is being bullied at work, a few things can be done. First, try to talk to the person who is doing the bullying. This can be difficult, but trying to resolve the issue is important. You can talk to a supervisor or the HR department if that does not work. They can help to investigate the situation and take action if necessary. Finally, you can also seek help from a professional counselor or therapist. They can provide support and guidance to help you cope with the situation.

2. Harassment

It is a common scenario in workplaces today. You are sitting in your chair, minding your business, when someone from the other side hurls a lewd comment your way. You are frozen in shock, not knowing how to react. This is just one example of the many ways in which people can be harassed at their workplaces.

While sexual harassment is the most common form of workplace harassment, there are other types. These include but are not limited to racial harassment, religious harassment, and disability-based harassment. Workplace harassment can have a severe impact on an individual’s mental health. It can lead to anxiety, depression, and post-traumatic stress disorder (PTSD).

If you are being harassed at work, you must reach out for help. Talk to a trusted friend or family member about what is going on. You can also contact a professional therapist or counselor to help you deal with the psychological effects of workplace harassment. Remember, you are not alone in this. There is help available if you reach out for it.

3. Stress

Stress is the number one psychological hazard in the workplace. It can lead to various problems, including anxiety, depression, gastrointestinal disorders, headaches, heart disease, sleep disorders, and stroke.

A number of things can cause stress in the workplace, including long hours, tight deadlines, heavy workloads, job insecurity, and conflict with co-workers.

There are several things you can do to manage stress in the workplace. These include:

- Taking breaks during the day

- Eating healthy foods

- Exercising regularly

- Getting enough sleep

- Avoiding caffeine and alcohol

- Practicing relaxation techniques such as yoga or meditation.

If you are feeling overwhelmed by stress, seeking help from a mental health professional is important. Left untreated, stress can lead to serious problems at work and in your personal life.

4. Violence

Violence can be defined as an act of aggression, whether physical or psychological, that is intended to hurt or kill. It can occur in the workplace, at home, or in public. According to the National Institute for Occupational Safety and Health (NIOSH), violence is a leading cause of death and injury in the workplace. In fact, it is the second leading cause of death for American workers, behind only car accidents.

Many factors can contribute to workplace violence, including job stress, bullying, and exposure to violence in the community. However, one of the most important risk factors is a history of violence or aggression. This includes a history of domestic violence, assault, or other violent crimes.

If you have a history of violence or aggression, getting help from a mental health professional is important before it leads to workplace violence. There are many resources available to help you deal with anger and aggression in a healthy way. With the right support, you can prevent workplace violence before it happens.

5. Public Health Hazards & Control Measures

Many potential public health hazards can occur when people do not have access to clean water. Waterborne diseases, such as cholera and typhoid fever, are a major concern in areas where water is contaminated. In addition, people who do not have access to clean water are at risk of developing skin infections and other health problems.

One of dirty water’s most significant public health hazards is the spread of waterborne diseases. Waterborne diseases are caused by bacteria, viruses, and parasites that can contaminate water supplies. These diseases can cause severe diarrhea, vomiting, dehydration, and even death. In areas where clean water is unavailable, people risk contracting waterborne diseases if they consume contaminated water or come into contact with it.

Another public health hazard associated with dirty water is the development of skin infections. Skin infections can occur when people come into contact with contaminated water. These infections can cause redness, swelling, and pain, sometimes leading to serious health problems.

Dirty water can also lead to other health problems, such as respiratory infections and digestive problems. In addition, dirty water can exacerbate existing medical conditions, such as asthma and allergies.

The best way to avoid public health hazards associated with dirty water is to ensure access to clean water. If you are unsure about the quality of your water supply, you should contact your local public health department or water utility company. You can also take steps to purify your water at home using a filter or boiling it before drinking it. These simple precautions can help protect yourself and your family from potential public health hazards.

Hierarchy Of Control Measures For Hazards

There are a variety of control measures that can be taken to mitigate the risks associated with hazards. The type of control measure that is most appropriate will depend on the specific hazard involved. Some common control measures include but are not limited to:

- Engineering controls

- Administrative controls

- Personal protective equipment

1. Engineering Controls

Engineering controls seek to eliminate or minimize exposure to a hazard by altering the work environment. Examples of engineering controls include but are not limited to:

- Local exhaust ventilation

- Machine guards

- Guardrails

2. Administrative Controls

Administrative controls seek to eliminate or minimize exposure to a hazard by altering how work is done. Examples of administrative controls include but are not limited to:

- Job rotation

- Workplace policies and procedures

- Training programs

3. Personal Protective Equipment

Personal protective equipment (PPE) is clothing, equipment, or a device that is worn by an individual to protect them from risks in the work environment. Examples of PPE include but are not limited to:

- Hard hats

- Safety glasses

- Earplugs

- Protective clothing

By understanding what hazard is, the different types of hazards, and the various control measures that can be taken to mitigate those risks, you can create a safer workplace for yourself and your employees.

Different Categories Of Hazards

The employer is responsible for identifying hazards. It’s helpful to categorize them into five categories:

- The first three categories (materials, equipment, and the environment) represent hazardous conditions. Hazardous conditions are the surface causes that account for only a tiny percentage of all workplace accidents.

- The fourth category (people) describes employee behaviors. Employee behaviors represent the surface causes that contribute to or cause a higher percentage of workplace accidents.

- The fifth category (system) identifies safety management systems weaknesses. They are the root causes that ultimately contribute to or cause most accidents.

Let’s review these five categories:

Materials: liquids, solids, and gases that can be hazardous to employees.

- Liquid and solid chemicals (such as acids, bases, solvents, and explosives) can produce harmful effects.

- Raw materials (solids like metal, wood, and plastic) used to manufacture products are usually bought in large quantities and can cause injuries or fatalities in many ways.

- Gases, like hydrogen sulfide and methane, may be extremely hazardous if leaked into the atmosphere.

Equipment: machinery and tools used to produce or process goods.

- Hazardous equipment that is improperly guarded and places workers in a danger zone around moving parts could cause injury or death.

- Lack of preventive and corrective maintenance will make it challenging to ensure equipment operates properly.

- Tools not in good working order, improperly repaired, or unused for their intended purpose are only accidents waiting to happen.

Environment: a general area that employees are working in.

- Poor facility design, hazardous atmospheres, temperature, and/or noise can cause stress.

- If areas in your workplace are too hot, cold, dusty, dirty, messy, or wet, then measures should be taken to minimize the adverse conditions.

- Extreme noise that can damage hearing should not be present.

- Workstations may be misdesigned, contributing to an unsafe environment.

People: employees, managers, and supervisors in the workplace.

- Unsafe employee behaviors include taking shortcuts or not using personal protective equipment.

- Employees working while fatigued, under the influence of drugs or alcohol, distracted for any reason, or in a hurry are “walking and working hazards.”

System: Ultimately, the root cause of most accidents is one or more weaknesses within the safety management system.

- Management may unintentionally promote unsafe behaviors. For example, they may ignore non-compliance.

- Inadequate or missing safety plans, programs, policies, processes, procedures, practices, and rules (written and unwritten) may result in workplace injury, illness, or death.

Conclusion

In essence, hazards are a part of our daily lives. They can come in various forms, from biological and psychological to public health hazards. Understanding hazards, their types, and their potential impact is fundamental in our quest to create safer spaces for ourselves and those around us.

Throughout this blog, we have delved into the diverse hazards world, unpacking their various forms and providing tangible examples. We have explored the complexities of hazards ranging from bacteria and viruses to stress and workplace bullying and the significant public health hazards arising from poor access to clean water.

But awareness is only the first step. Knowing how to control and manage these hazards is crucial. With the various control measures discussed, from engineering and administrative controls to personal protective equipment, we hope you have gained insight into creating a safer environment in your home, workplace, and public areas.

In the end, hazards will always exist, but their negative impact doesn’t have to. We can significantly reduce the risk they pose through vigilance, education, and proper control measures. Let’s carry forward the knowledge gained for our benefit and educate and protect those around us. Remember, safety isn’t merely a personal responsibility; it’s a collective endeavour.

Stay safe and continue to learn and educate. After all, understanding hazards and their control is an ongoing process, vital for our well-being and our communities.