Cranes play a vital role in the construction industry, enabling the safe and efficient movement of heavy loads on construction sites. However, the operation of cranes requires effective communication between the crane operator and the signal person to ensure safety and precision. In this blog post, we will explore the crucial topic of crane operator signals and delve into three primary methods of crane signaling.

Understanding and employing these methods correctly is essential for maintaining a secure working environment and preventing accidents on construction sites. So, whether you are a crane operator, a signal person, or simply interested in construction safety, read on to discover the key methods of crane signaling that keep operations running smoothly and safeguard lives.

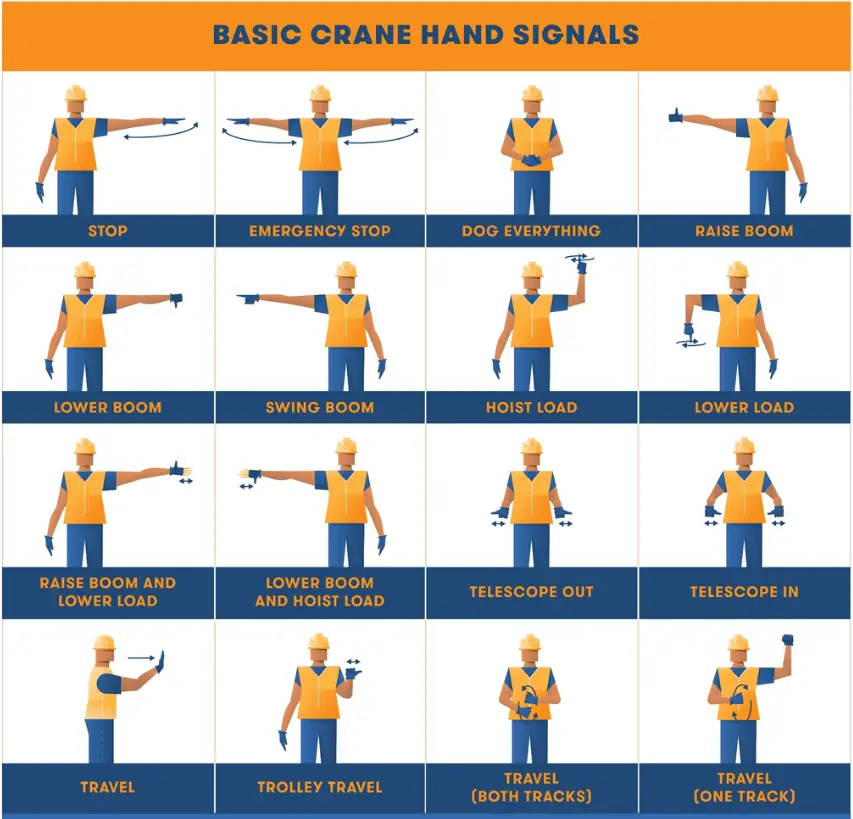

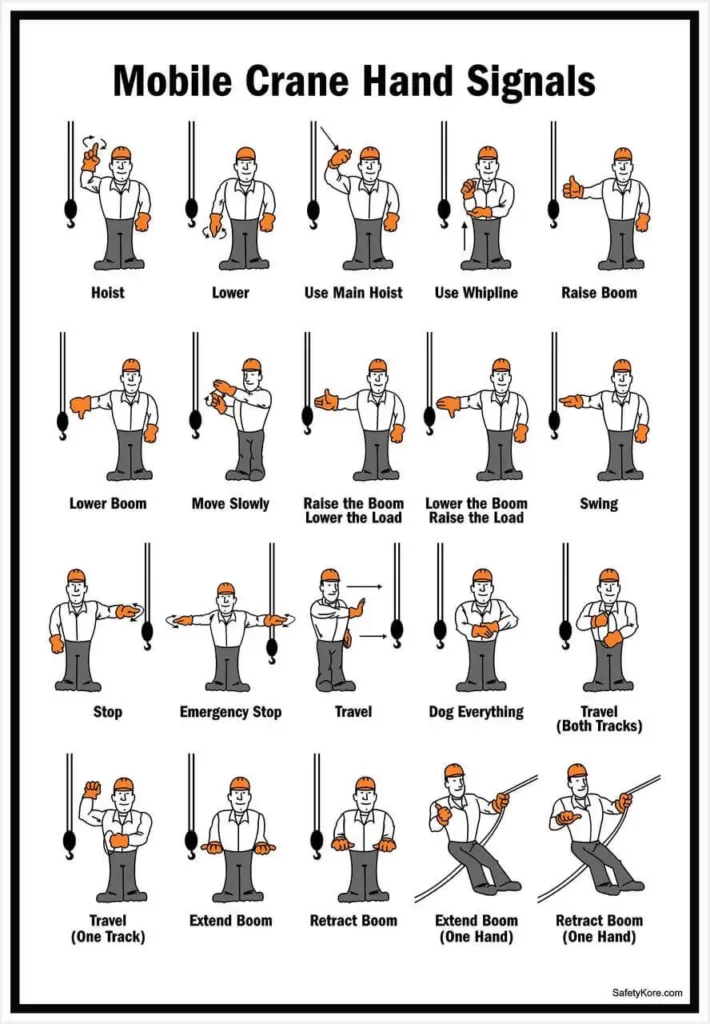

Cranes are the most effective way to move heavy loads on a construction site, and proper use of crane hand signals is a vital part of safe operation. After learning basic crane hand signals, a signal person can safely direct a crane operator to raise and lower the boom, hoist and lower the load, or move the load horizontally — and, of course, stop the crane in case of emergency.

Importantly, the Occupational Safety and Health Administration requires that anyone designated as a signal person must meet certain qualifications and be evaluated by a qualified individual. According to the Bureau of Labor Statistics, these regulations and a commitment to standardized signals have helped reshape the landscape of crane safety, with crane-related deaths falling to their lowest recorded level in 2017.

Crane Signals

Crane signals are standardized communication methods used between crane operators and signal persons to safely maneuver cranes during various lifting and moving operations on construction sites or industrial areas. These signals are essential for ensuring the safety and efficiency of crane operations, especially when the crane operator does not have a clear line of sight or when specific safety concerns require precise communication.

A crane operator often needs a signal person to operate safely. A signal person must be provided:

- When the point of operation, meaning the path the load travels or the area where the load is placed, is not in full view of the operator;

- When the equipment is traveling, and the operator’s view in the direction of travel is obstructed; or

- When, due to site-specific safety concerns, either the operator or the person handling the load determines that it is necessary.

The ability to transmit signals between the operator and the signal person must be maintained during operations requiring signals. If that ability is interrupted, the operator must safely stop operations until the signal transmission is reestablished and a proper signal is given and understood. Only one person may signal a crane/derrick at a time, though any person may give an emergency stop signal.

3 Methods Of Crane Signaling

There are three primary methods of crane signaling which are crucial for safely and efficiently operating cranes on construction sites and in other settings:

- Crane Hand Signals

- Crane Voice Signals

- Crane Audible Signals

1. Crane Hand Signals

Hand signals are visual gestures a signal person makes to guide the crane operator. This method is primarily used when the operator and signal person are in sight of each other. There are standard hand signals that are universally recognized. For example:

- Raising one arm vertically means “hoist.”

- Moving one arm horizontally means “move slowly.”

- Clasping both hands together above the head means “emergency stop.”

These standard hand signals are crucial for safety and consistency. The signal person must be properly trained in these signals, and charts depicting the standard hand signals should be visible on the crane or nearby for reference.

2. Crane Voice Signals

Voice signals involve the signal person using oral communication to guide the crane operator. This method is useful when the operator and signal person is at a distance from each other or if the operator is inside a cabin where hand signals may not be easily visible.

- Before operations start, there must be a clear agreement on the specific voice commands.

- Communications equipment such as radios or intercom systems may be used to amplify or transmit voice signals.

- Standardized terms like “hoist,” “lower,” “boom up,” etc., are commonly used.

3. Crane Audible Signals

Audible signals are non-verbal sounds used to communicate specific instructions. They are often used in environments where visual signals might not be effective due to distance, poor visibility, or the operator being in an enclosed cabin.

- These can include sounds from bells, horns, or whistles.

- Each sound or series of sounds corresponds to a specific instruction.

- For example, a short horn blast might mean “stop,” while two short blasts might mean “lower.”

- The meaning of each sound must be agreed upon and understood by both the signal person and the operator before operations begin.

Additionally, as technology evolves, new methods are being developed, such as:

New Signal Methods

This category encompasses emerging technologies and methods that enhance or replace traditional signaling methods. For example:

- Video Cameras: Video monitoring systems can be used when the line of sight is unclear. The signal person can watch the crane’s operation on a screen and communicate with the operator through radio or other means.

- Sensors and Alarms: Advanced sensors can detect proximity to objects, and automated alarms can warn the operator of potential hazards.

These new methods should meet all OSHA requirements for signaling and be agreed upon by all parties involved in the crane operation.

Conclusion

In conclusion, crane hand signals are essential to safe and effective operation on a construction site. The signal person and the operator must clearly understand the different signaling methods. When used correctly, these signals can help prevent accidents and fatalities while keeping everyone on the worksite safe. All employers should ensure that their operators and signal persons are thoroughly trained in safely using hand signals and other signaling methods.

Furthermore, employers must ensure that all workers exposed to crane-related hazards follow all safety protocols and regulations set by OSHA when working near a crane. This can help create an environment freeing everyone from injury or harm.