In the demanding world of construction and industrial operations, handling suspended loads is an everyday reality. Despite its routine nature, the process presents a range of potential hazards that demand serious attention and strict safety measures. This blog post delves into the crucial subject of suspended load safety. We discuss what constitutes a suspended load, the inherent risks, examples of common hazards, and an extensive array of safety tips and guidelines.

Whether you’re an employer, a safety officer, or a worker in an environment where suspended loads are commonplace, this article provides valuable insights and guidelines to ensure safety is paramount. As the saying goes, “An ounce of prevention is worth a pound of cure.” Let’s delve in and explore how we can make working with suspended loads safer.

What Is a Suspended Load?

A suspended load refers to any material or object lifted and held above the ground by a mechanical device or equipment. This can include but is not limited to, items such as construction materials, containers, machinery, or any other heavy objects lifted and suspended in the air by cranes, hoists, forklifts, or other lifting equipment.

In construction and industrial settings, suspended loads are often managed using rigging equipment such as chains, cables, slings, and hooks. The term ‘suspended load’ highlights that the object or material is not supported by a solid surface but rather is hanging in the air and therefore requires careful handling and safety precautions to prevent accidents or injuries. When not managed properly, suspended loads can be unstable and pose significant hazards to nearby people and property.

Suspended loads are not limited to industrial settings. In geological terms, ‘suspended load’ refers to the sediment carried by a stream in the water column rather than on or near the stream’s bed. This sediment is held up by the turbulence in the flowing water and consists mainly of particles like silt and clay.

Suspended Load Examples

Suspended loads can be found in various industries and work environments. Here are a few examples to illustrate the diversity and scale of suspended loads:

- Construction Site Materials: On construction sites, cranes often suspend loads such as steel beams, concrete blocks, and prefabricated components. These materials are lifted and moved to specific locations as required for building structures.

- Shipping Containers: At ports, large cranes, called container cranes, are used to load and unload shipping containers from cargo ships. These containers can be very heavy and are often suspended high above the ground during the loading/unloading.

- Vehicle Repairs: In auto repair shops, engines or other heavy components are often suspended from hoists or lifts during repair or replacement.

- Warehouse Inventory: In warehouses, forklifts are used to lift, move, and store heavy pallets of goods. These pallets are suspended from the forklift’s prongs during transportation.

- Logging Operations: Trees cut down are often suspended by cranes or other heavy machinery cables and transported to a different location.

- Wind Turbine Installation: When installing wind turbines, heavy components like the nacelle, tower sections, and blades are lifted by cranes and suspended at great heights to be assembled.

- Theatrical and Event Rigging: In theaters and event venues, lighting, sound equipment, and scenery are often suspended above the stage using rigging systems.

- Manufacturing Assembly Lines: In manufacturing plants, assembly lines often use overhead conveyor systems to suspend and move parts or products through various stages of assembly.

- Helicopter Aerial Lifts: In remote areas or in emergencies, helicopters are used to airlift heavy equipment or supplies. These loads are suspended beneath the helicopter by cables.

- Mining Operations: Various materials and equipment are often moved using cranes or hoists. This includes lifting ore, heavy machinery, and other materials in and out of mines.

These examples illustrate the broad range of situations in which loads are suspended. Safety precautions must be rigorously observed in all these cases to prevent accidents and injuries.

Importance Of Safety When Working Under A Suspended Load

The importance of safety when working under or around a suspended load cannot be overstated. Below are some of the key reasons why safety should be the utmost priority in such scenarios:

- Preservation of Life and Prevention of Injuries: The primary reason for emphasizing safety is to preserve human life and prevent injuries. Suspended loads, if not managed properly, can fall, leading to fatal accidents or causing severe injuries to the workers.

- Legal Compliance: Adhering to safety standards is not just a moral obligation but a legal requirement. Many countries ‘ occupational health and safety regulations mandate that employers provide a safe working environment. Non-compliance can lead to legal consequences, including fines and, in severe cases, imprisonment.

- Protecting Equipment and Property: Besides the human aspect, a falling load can cause significant damage to equipment and property. Adhering to safety procedures can minimize the risk of damage to valuable assets.

- Operational Continuity and Productivity: Accidents can cause work stoppages and delays. Maintaining a safe work environment ensures operations continue smoothly and without interruptions, contributing to overall productivity.

- Worker Morale and Retention: A safe work environment produces high employee morale. Workers who feel that their safety is a priority are more likely to be satisfied with their jobs and remain with the company. This reduces turnover and the associated costs of hiring and training new employees.

- Reputation Management: Accidents and unsafe practices can tarnish a company’s reputation. A company known for prioritizing safety is more likely to be trusted by its clients and partners, and it can attract top talent in the industry.

- Financial Costs: Accidents can result in significant financial costs, including medical expenses, compensation to injured employees, repair or replacement of damaged equipment, and potential legal fees and fines. By investing in safety, companies can avoid these costs.

- Insurance Premiums: Consistently safe operations may lead to lower insurance premiums. Insurance companies often provide incentives or discounts to companies that maintain high safety standards.

- Regulatory Compliance and Auditing: Maintaining safety when working with suspended loads can facilitate the fulfillment of regulatory compliance and pass safety audits with ease. This could lead to qualifications for certain industry certifications and standards that might give a competitive advantage.

- Social Responsibility: Companies have a social responsibility to ensure the safety and well-being of their workers. This extends to the communities in which they operate. Ensuring safety when working under suspended loads is part of fulfilling this responsibility.

In summary, the importance of safety when working under a suspended load is multifaceted, encompassing human, economic, legal, and social dimensions. Employers must understand these aspects and implement comprehensive safety measures accordingly.

Suspended Load Hazards

Suspended load hazards refer to the potential dangers and risks associated with handling and being in the vicinity of loads lifted and suspended in the air by equipment such as cranes, hoists, and forklifts. These hazards can result in accidents, injuries, or even fatalities if not properly managed. Some of the common suspended load hazards include:

- Falling Loads: One of the most obvious hazards is the risk of the load falling. This can be due to equipment failure, improper rigging, or overloading. A falling load can cause severe injuries or fatalities.

- Swinging or Shifting Loads: A suspended load may begin to swing or shift, especially if it’s not properly balanced. This can make it unpredictable and dangerous for those in the vicinity.

- Crushing Hazards: If a suspended load is moved improperly, individuals are likely caught between the load and another object or surface, which could result in crushing injuries.

- Rigging Failure: The failure of slings, chains, hooks, or other rigging equipment can cause the load to be released unexpectedly.

- Load Ejection: If a suspended load contains loose materials, these might be ejected from the load during movement, potentially striking and injuring workers.

- Overloading: Lifting a load that exceeds the safe working load limit of the lifting equipment can cause structural failures in the lifting equipment or rigging.

- Structural Collapse: The weight of a suspended load could potentially cause a structure, such as a crane, to collapse if the structure cannot support the load.

- Electric Shock: When operating lifting equipment, there’s a risk of coming into contact with overhead power lines. This can cause electric shocks or electrocution.

- Poor Visibility: Operators might not have a clear view of the suspended load or the surrounding area, increasing the risk of an accident.

- Inadequate Communication: In environments where suspended loads are being moved, poor communication between the equipment operators and the ground crew can lead to misunderstandings and accidents.

- Inadequate Training and Experience: Operators and workers who are not adequately trained or lack experience handling suspended loads can make mistakes contributing to accidents.

To mitigate these hazards, it is critical to follow safety protocols, use proper equipment, ensure good communication, and provide adequate training for all personnel involved in operations with suspended loads. Regular equipment maintenance and inspection are also vital in minimizing these hazards.

Suspended Loads Safety Tips – Working Under Suspended Loads Safely

Safety while working with suspended loads is critical to prevent accidents and injuries. Here are some safety tips that should be followed:

- Proper Training: All personnel handling suspended loads should undergo comprehensive training programs. This should include understanding the equipment’s operational limits, how to inspect the equipment, proper rigging techniques, and how to respond to emergencies. Refresher training should also be conducted periodically to ensure the workers stay updated.

- Use Personal Protective Equipment (PPE): Workers should use PPE such as hard hats to protect against falling objects, safety glasses to shield the eyes from debris, gloves to protect hands from sharp or rough materials, and steel-toed boots to protect feet from heavy falling objects. Wearing high-visibility clothing is also crucial to ensure equipment operators easily see workers.

- Regular Equipment Inspection: Cranes, hoists, slings, and other equipment should be inspected regularly for wear and tear, corrosion, or other damage. Qualified professionals should perform these inspections, and any equipment that is found to be damaged should be repaired or replaced before being used again.

- Know the Load Limits: It’s essential to know the weight of the load and ensure it doesn’t exceed the maximum load capacity of the lifting equipment. Exceeding the load limit can cause the equipment to fail, leading to catastrophic accidents. The weight and load limits should be clearly marked on all lifting equipment.

- Ensure Proper Load Balancing and Securing: Before lifting, it’s critical to ensure the load is evenly balanced and secured properly. Uneven loads can shift during lifting, potentially causing the load to fall or the equipment to become unstable.

- Maintain Clear Communication: There should be a system for clear communication between the personnel involved in the lifting operation. This could include using radios for verbal communication or establishing a set of hand signals to communicate visually. The latter is particularly useful in noisy environments.

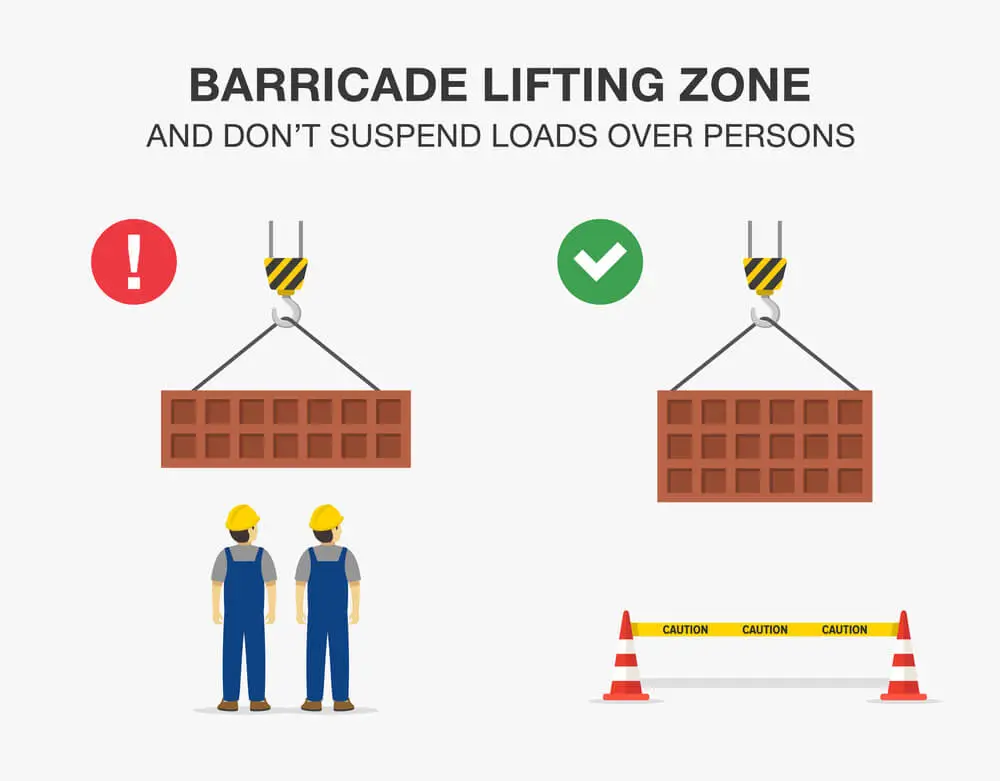

- Establish a Safety Zone: Mark a clear area around the location where lifting operations occur. This area should be kept free of all non-essential personnel. Barriers and signage should be used to keep people out of this area while lifting is in progress.

- Be Mindful of Overhead Power Lines: Lifting equipment and loads should be kept safe from overhead power lines. Contact with power lines can cause electrocution. Planning and surveying the site to identify the location of power lines is critical.

- Plan Lifts Carefully: A detailed lift plan should be prepared, which includes load weight, equipment capacity, lift path, and potential obstructions or hazards. This plan should be communicated to all personnel involved in the lifting operation.

- Smooth and Slow Operations: Sudden movements can cause the load to become unstable. Lifting and moving operations should be done smoothly and slowly to ensure the safety and control of the load.

- Monitor Weather Conditions: Adverse weather, such as high winds, heavy rain, or snow, can make lifting operations more dangerous. Monitoring weather conditions and postponing operations in adverse conditions is critical.

- Stay Vigilant and Focused: Distractions can be deadly during lifting operations. All personnel involved should be focused and vigilant throughout the operation. Personal electronics such as mobile phones should be prohibited.

- Emergency Procedures: All personnel should be trained in emergency response procedures. This includes knowing how to quickly shut down equipment and respond if something goes wrong.

- Documentation and Compliance: It’s crucial to maintain proper documentation, including inspection records, training records, and lift plans. Ensuring compliance with local, state, and federal regulations is a legal requirement and critical for maintaining safety standards.

Additional Suspended Loads Safety Rules

- Avoid Working Under Suspended Loads: Workers should never position themselves under a suspended load. In cases where it is absolutely necessary to be under a suspended load, special precautions, and planning should be employed to mitigate the risks.

- Use Tags and Barricades: When lifting operations are being conducted, using tags and barricades to mark the area can help prevent unauthorized or unaware individuals from entering a potentially dangerous zone.

- Use Spotters: When a load is being moved, especially in congested areas, have a person dedicated to watching the surrounding area to ensure that the path is clear and that no one enters an unsafe area during the move.

- Load Testing: Before beginning a critical lift, it’s advisable to perform a load test with a weight at or above the weight of the load to be lifted. This ensures that the equipment can safely lift and move the load.

- Use of Redundant Systems: When lifting very heavy or critical loads, redundant systems, such as using multiple slings and ensuring that the failure of one component will not result in an uncontrolled release of the load, is vital.

- Routine Maintenance: According to the manufacturer’s recommendations, regular crane and lifting equipment maintenance is essential. Proper maintenance helps in preventing mechanical failures that could cause an accident.

- Good Housekeeping: Keep the area around the load and the path where the load will be moved clear of debris, tools, or any other items that could cause tripping or other hazards.

- Lighting Conditions: Ensure that the area where lifting operations are conducted is well-lit. If operating during hours of darkness, additional lighting should be employed.

- Addressing Psychological Factors: Ensure that the operators and workers are not under stress or fatigue, which can impair judgment and reaction times.

- Emergency Stop Systems: Ensure that cranes and other lifting equipment have an easily accessible emergency stop system and that all operators are trained.

- Inspection of Load Attachments: Before lifting, inspect chains, slings, hooks, and other attachments to ensure they are in good condition, suitable for the load, and securely attached.

- Clear Roles and Responsibilities: Before starting lifting operations, clearly define each team member’s roles and responsibilities. This will prevent confusion and ensure that important safety steps are not overlooked.

- Monitor Load Stability During Lifting: During the lifting operation, continuously monitor the load for movement or instability. If any instability is observed, lower the load immediately to a safe location.

- Public Safety: If lifting operations occur near public areas, take extra precautions to ensure the public’s safety. This might include additional barriers, signs, or having personnel dedicated to keeping the public at a safe distance.

- Lifting in Adverse Weather Conditions: If lifting must be performed in adverse weather conditions, take additional safety precautions, such as reducing load weights and movement speeds and using additional personnel to monitor the operation.

- Documentation of Incidents and Near Misses: Record any incidents or near misses, regardless of whether an injury occurred. Analyzing this information can help in identifying potential problems and preventing future incidents.

By implementing these detailed safety tips, organizations can greatly reduce the risks of handling suspended loads and create a safer working environment.

Conclusion

In conclusion, handling suspended loads is a complex and potentially hazardous operation requiring vigilance, training, and adherence to safety protocols. Understanding the risks and implementing preventive measures is crucial in construction, industrial environments, or any setting involving lifting and moving heavy objects.

By fostering a safety culture, ensuring proper training, utilizing appropriate equipment, and closely following safety guidelines, organizations can safeguard human lives and assets, enhance operational efficiency, maintain a positive reputation, and fulfill legal and social responsibilities. It’s incumbent upon all stakeholders to recognize the gravity of the hazards associated with suspended loads and to actively engage in minimizing risks through educated and prudent practices.