In the vast landscape of workplace safety, the term “Line of Fire” frequently emerges as a focal point of discussion, often leaving many pondering its exact implications. Yet, its significance cannot be overstated. “What’s The Line of Fire Hazards?” delves deep into this critical safety concept, unravelling its categories and shedding light on how to circumvent potential threats.

By comprehending the nature and subcategories of these hazards, we can foster safer work environments and minimize the risk of unfortunate incidents. Whether you’re a seasoned professional or someone new to workplace safety, this blog promises to equip you with valuable insights to keep danger at bay. Join us as we navigate the intricate dynamics of Line of Fire Hazards, ensuring that safety remains a priority and a culture.

What is the Line of Fire Safety?

“Line of Fire” safety refers to understanding, identifying, and mitigating the risks associated with being in harm’s way during various job tasks, especially in industrial and construction environments. When someone is in the “line of fire,” they are in a position where they could get hurt due to moving machinery, falling objects, released energy, or other hazards.

Key concepts of “Line of Fire” safety include:

- Awareness of Surroundings: Workers should always be aware of their immediate surroundings, particularly when working near machinery, elevated objects, or any area with moving parts or potential energy release.

- Understanding Potential Hazards: Recognizing the sources and types of hazards in one’s work environment can significantly reduce the chances of injuries. Examples include machinery with moving parts, suspended loads, pressurized systems, and even vehicles in motion.

- Use of Protective Barriers and Equipment: Wherever feasible, barriers, guards, and other protective devices should shield workers from potential hazards. This could be physical barriers around a machine or safety nets to catch falling objects.

- Proper Training: Workers should be adequately trained to recognize and mitigate line of fire hazards. This includes understanding the machinery they’re using, the signs of potential equipment failure, and the safe zones in their working area.

- Continuous Communication: Clear communication can prevent mishaps in team settings, especially in noisy environments. This could involve using hand signals, whistles, or other established communication protocols.

- Routine Inspections: Regularly inspecting machinery, equipment, and work areas can identify potential hazards before they become critical issues.

In essence, “Line of Fire” safety is about understanding the direct path between a hazard and a potential injury and taking proactive steps to ensure that workers are never positioned in that path without adequate protection.

What is the Line of Fire Hazards?

“Line of Fire” hazards refer to situations where workers are put in the direct path of a powerful force. This force could be a moving object, releasing energy, or other situations where being in the wrong place at the wrong time can result in injury or fatality. Understanding and identifying these hazards is crucial for workplace safety.

In essence, to be in the line of fire means you are in harm’s way or in a position where a particular process or equipment could hurt you. This term is used primarily in the context of workplace safety to identify and prevent potential injury scenarios.

The Importance of Identifying Line of Fire Hazards

Countless professionals across diverse industries clock into their respective work environments daily. These settings, from construction sites to manufacturing floors, often buzz with activity – machines roar to life, tools clatter, and workers navigate tasks with well-practised precision. Yet, lurking among these routines are potential threats, often unperceived, waiting for just one misstep. These threats are termed ‘Line of Fire hazards, and understanding them is paramount to ensuring the safety of every individual in the workplace.

- The Ubiquity of the Threat: Firstly, the omnipresence of Line of Fire hazards makes it essential for professionals to be aware of them. They aren’t exclusive to high-risk jobs or large machinery operations. A simple office setting can pose a Line of Fire hazard in the form of a loose cable, while a construction site may have multiple such hazards with moving vehicles, swinging equipment, or collapsing structures. The universality of these threats means that no industry can afford to overlook their potential occurrence.

- Prevention Over Cure: Like many other risks, the consequences of Line of Fire hazards can range from minor injuries to fatal accidents. By identifying these hazards, we lean more towards prevention than reacting to an incident after it has happened. Early identification means that corrective measures can be taken in advance, thus dramatically reducing the chances of an unfortunate event.

- Economic Implications: Beyond the human cost, failing to identify and address the Line of Fire hazards can also bear significant financial burdens on companies. These may include medical expenses, lost workdays, compensations, and potential legal fees. Proactively addressing these hazards not only safeguards the well-being of the employees but also acts as a buffer against unforeseen financial drains.

- Cultivating a Culture of Safety: Identifying the Line of Fire hazards isn’t just about identifying the obvious risks. It’s about fostering an environment where safety becomes an ingrained culture. When workers are trained to spot and report these hazards, they become active participants in creating a safer workspace. Such proactive measures increase employee trust, knowing their well-being is a priority.

- Keeping up with Evolving Workspaces: As industries evolve and work processes adapt to new technologies and methodologies, the nature and scope of Line of Fire hazards also transform. Constant vigilance in identifying these ever-evolving threats ensures that safety measures aren’t stuck in the past but are always ahead of potential dangers.

Identifying a Line of Fire hazard is not merely a box to tick off in a safety checklist. It’s an ongoing commitment to ensure that every individual returns home in the same health and well-being as when they arrived at work. We can significantly reduce these hidden threats through awareness, training, and proactive measures, making workplaces more productive and safer for all.

Major Categories of Line of Fire Hazard Incidents

Line of fire hazards refer to situations where a person is in the direct path of a moving object or force, posing a risk of injury. These incidents can occur in various settings, including workplaces, construction sites, industrial facilities, and more. Here are some major categories of line of fire hazard incidents:

1. Stored Energy Hazards

Stored energy hazards refer to situations where energy is accumulated within a system or device and can be suddenly released, posing a risk to anyone nearby. For example, pressurized systems such as air tanks or hydraulic systems store energy that, if released unexpectedly, can cause harm. Similarly, compressed springs in machinery or automotive parts contain potential energy that can be dangerous if the spring suddenly expands. Suspended weights, such as a heavy object held by a crane, can also be a source of stored energy, as the weight can fall if not secured properly, causing injury or damage.

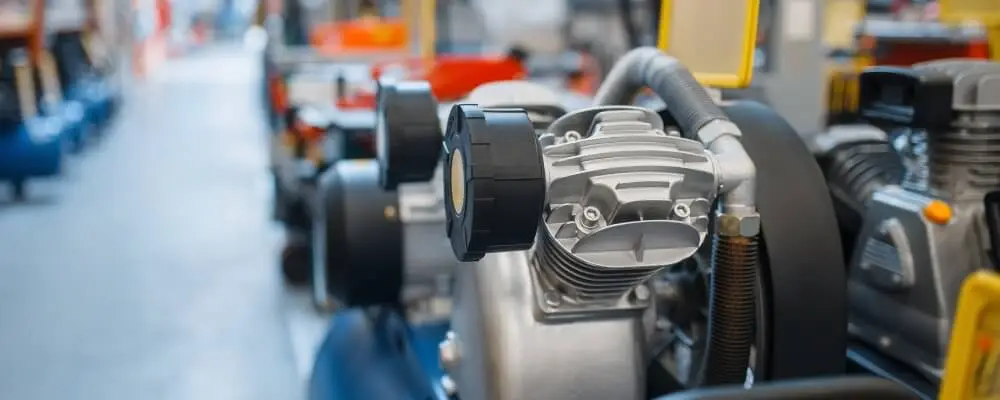

2. Equipment and Tools Hazards

Equipment and tools, especially power ones, are essential in many work environments but come with inherent risks. Power tools and machinery often have moving parts that can pose threats if one comes into contact with them. For instance, the rotating blade of a circular saw or the moving chain of a chainsaw can inflict severe injuries. Additionally, many machines have pinch points where two parts move together, and sharp edges, both of which can cause cuts, bruises, or more severe injuries if workers aren’t careful.

3. Falling Object Hazards

This category encompasses risks associated with objects that fall from a height, potentially striking workers or equipment below. Such situations can arise when tools or materials aren’t secured properly at elevated work sites, like scaffolding or on top of machinery. Furthermore, any work done overhead, such as construction tasks on an upper floor or maintenance work on ceilings, poses a risk if precautions aren’t taken to secure tools and materials. Even a small tool dropped from a significant height can cause severe injury upon impact.

4. Motions and Actions Hazards

Certain work activities require repetitive or sudden body movements, and these motions can lead to strains, sprains, or other musculoskeletal injuries. For example, repeatedly lifting heavy objects can strain the back, while sudden movements to avoid equipment or materials can cause sprains or falls. Additionally, being in close proximity to moving vehicles or equipment, such as forklifts in warehouses or heavy machinery at construction sites, poses risks. If workers aren’t vigilant about their surroundings, they can be struck by or caught in these moving entities.

5. Material Ejection Hazards

Some machines are designed to process or handle materials, and there’s potential for ejection during this handling. Wood chippers, for instance, can eject wood fragments at high speeds, posing a danger to anyone in the line of fire. Similarly, saws can send shards flying, especially when cutting brittle materials. Without proper guarding or personal protective equipment, workers risk being struck by these ejected materials, leading to lacerations, punctures, or eye injuries.

Effective Tips On How To Avoid Line of Fire Incidents

Avoiding Line Fire incidents is crucial for ensuring workplace safety. Here are some effective tips to help prevent such occurrences:

- Risk Assessment: Before starting any task, conduct a thorough risk assessment. This involves identifying potential hazards, evaluating their associated risks, and determining appropriate preventive measures.

- Safety Training: Regularly train all employees about the dangers of Line of Fire incidents. Ensure they understand the risks associated with their specific jobs and the precautions they must take.

- Clear Communication: Always communicate clearly and effectively. Workers should be encouraged to voice concerns, ask questions, and report any unsafe conditions or practices they observe.

- Maintain Equipment: Regularly inspect and maintain machinery and equipment to ensure they function correctly and safely. Defective or worn-out equipment is a significant contributor to Line of Fire incidents.

- Use Personal Protective Equipment (PPE): Ensure workers use the appropriate PPE for their tasks. This can include hard hats, safety glasses, gloves, and high-visibility clothing.

- Design Safe Work Areas: Layout work areas to minimize exposure to Line of Fire hazards. This could involve setting up barriers, designated walkways, or safety zones around dangerous equipment.

- Follow Procedures: Always follow established safety procedures and protocols. Never bypass safety mechanisms or take shortcuts.

- Stay Alert: Encourage workers to remain alert and aware of their surroundings. Distractions can lead to accidents, so staying focused on the task is essential.

- Use Signage: Display clear warning signs and labels in areas with potential Line of Fire hazards. This serves as a visual reminder for workers to exercise caution.

- Limit Exposure: Automate hazardous tasks or use remote-control tools to minimize direct human exposure to potential dangers whenever possible.

- Lockout/Tagout Procedures: Ensure machinery is fully shut down, and energy sources are isolated during maintenance or repair to prevent unintentional startups.

- Regular Safety Drills: Conduct regular safety drills simulating different Lines of Fire scenarios to keep workers prepared and aware.

- Emergency Plans: Have a comprehensive emergency response plan in place. Workers should know what to do in case of an incident, including how to shut down machinery and alert medical personnel.

- Housekeeping: Maintain a clean and organized work environment. Clutter can obscure hazards or create additional ones.

- Monitor Worksite Activities: Supervisors should actively monitor worksite activities, ensuring that workers follow safety protocols and conditions to remain safe.

- Feedback Loop: Create a system where workers can provide feedback about safety concerns or suggest improvements. Their insights from the ground can be invaluable in identifying and mitigating potential risks.

Remember, the best way to manage a Line of Fire hazards is through training, awareness, equipment maintenance, and vigilance. Ensuring everyone is committed to safety is essential for minimizing risks and protecting workers.

The Role of Technology in Preventing Line of Fire Hazards

The digital age has transformed countless sectors, streamlining processes and introducing unprecedented innovations to revamp how we operate. One crucial domain that has significantly benefited from these advancements is workplace safety, especially in mitigating Line of Fire hazards. From advanced sensors to artificial intelligence, technology now plays an instrumental role in predicting, identifying, and preventing these risks, ensuring the safety of workers in diverse environments.

1. Advanced Surveillance and Sensors

With the advent of smart sensors and high-definition surveillance cameras, monitoring large industrial areas or intricate machinery has become easier and more precise. These sensors detect unusual activities, equipment overheating, or potential machinery failures. Providing real-time feedback allows supervisors to take immediate corrective actions, averting potential Line of Fire incidents.

2. Wearable Technology

Wearable devices equipped with advanced sensors can alert workers about potential hazards in their vicinity. For example, hard hats with proximity sensors warn workers of approaching heavy machinery or potential overhead risks. Similarly, smart gloves can vibrate or sound an alert if a worker’s hand is too close to a potential pinch or caught-in point.

3. Virtual Reality (VR) and Augmented Reality (AR) Training

Before workers set foot on an actual worksite, VR and AR can simulate real-world scenarios, allowing them to experience potential Lines of Fire hazards in a controlled environment. This immersive training enables workers to identify and respond to threats, equipping them with the skills and reflexes they need in real-life situations.

4. Drones and Automated Inspections

Drones equipped with cameras and sensors can access hard-to-reach places, providing a bird’s eye view of large construction sites or industrial areas. This reduces the need for manual inspections, potentially exposing workers to Line of Fire hazards and offers detailed, comprehensive data that might not be visible from ground level.

5. Machine Learning and Predictive Analysis

Machine learning algorithms can predict potential failures or malfunctions by analyzing vast amounts of data from various equipment and machinery. Predictive analysis can forewarn supervisors about parts that are likely to fail or machinery that might malfunction, allowing for timely maintenance and reducing the risk of sudden breakdowns that could pose Line of Fire hazards.

6. Internet of Things (IoT) for Safety Integration

The IoT allows for interconnected safety systems. This means wearable tech, machinery sensors, and other safety devices can communicate. If one device detects a potential hazard, it can instantly relay that information to other connected systems, ensuring a coordinated and immediate response to any threat.

7. Mobile Apps for Real-Time Reporting

Numerous safety apps now enable workers to report potential hazards instantly. These apps can also integrate with other safety systems, sending alerts to supervisors or shutting down machinery if a Line of Fire hazard is detected.

As industries evolve and the nature of work changes, so do the associated risks. Fortunately, the rapid advancement of technology offers solutions that adapt to these evolving challenges and proactively work towards eliminating them. Embracing these technologies ensures a safer work environment, minimizing Line of Fire hazards and promoting a culture where safety and innovation go hand in hand.

Conclusion

In the intricate tapestry of workplace safety, understanding the concept of “Line of Fire” hazards stands paramount. While varied in nature, these hazards all share a common thread: the potential to cause harm when individuals find themselves unwittingly in harm’s way. By categorizing and dissecting these risks, we’ve taken a significant step toward preemptive safety measures. However, mere awareness isn’t enough. Proactive measures, continuous training, and cultivating a safety-first mindset are essential to ensure these hazards remain theoretical and don’t translate into real-world mishaps.

As we conclude our exploration into the Line of Fire hazards, it becomes evident that knowledge is our first line of defense. Armed with this understanding, we can champion safer workplaces where everyone is aware of potential dangers and empowered with strategies to sidestep them. Safety isn’t a one-time task; it’s an ongoing commitment, and with the insights from this blog, we’re one step closer to a hazard-free work environment.