I remember walking onto a massive EPC site where the air was thick with more than just dust—there was a palpable sense of dread. During a routine site walkthrough, I noticed workers wouldn’t make eye contact, and supervisors were visibly shaking while answering basic questions about their logbooks. Later that week, a senior engineer resigned without a backup plan, citing “mental exhaustion.” It wasn’t just a tough project; it was a textbook case of a toxic culture where the pressure to perform had completely eroded the safety margins and the dignity of the workforce.

Identifying these red flags is not about HR buzzwords; it is about survival. A toxic workplace is a breeding ground for catastrophic incidents, as psychological distress leads to cognitive failure, bypassed procedures, and eventual physical harm. This article breaks down the specific indicators of toxicity from a field-level perspective so you can recognize when a job site has crossed the line from “challenging” to “dangerous.”

TL;DR

- Trust Your Health: Chronic stress, burnout, and physical symptoms are often the first objective indicators of a systemic HSE failure.

- Watch the Revolving Door: High turnover is rarely a “coincidence”; it is a symptom of a failure in leadership and psychological safety.

- Identify Communication Gaps: Information hoarding and “management by fear” create critical safety risks in high-hazard environments.

- Prioritize Integrity: When ethical shortcuts or “production over safety” become the norm, the workplace has become toxic and dangerous.

What is a Toxic Workplace?

In my experience as an HSE Manager, I define a toxic workplace as an environment where the culture, leadership, or peer dynamics actively undermine the well-being and safety of the employees. It is a place where “the way we do things here” contradicts the written policies and basic human respect.

- Psychological Unsafe Haven: A site where people are afraid to report near-misses for fear of retribution.

- The “Meat Grinder” Mentality: Treating human capital as a disposable resource to achieve a project milestone.

- Policy-Reality Gap: When the safety manual says one thing, but the supervisor’s verbal instructions say another.

Signs Of A Toxic Workplace

Recognizing the warning signs of a toxic workplace is essential for protecting your professional integrity and physical safety. These indicators often manifest as subtle cultural shifts before evolving into the systemic failures that cause catastrophic site incidents.

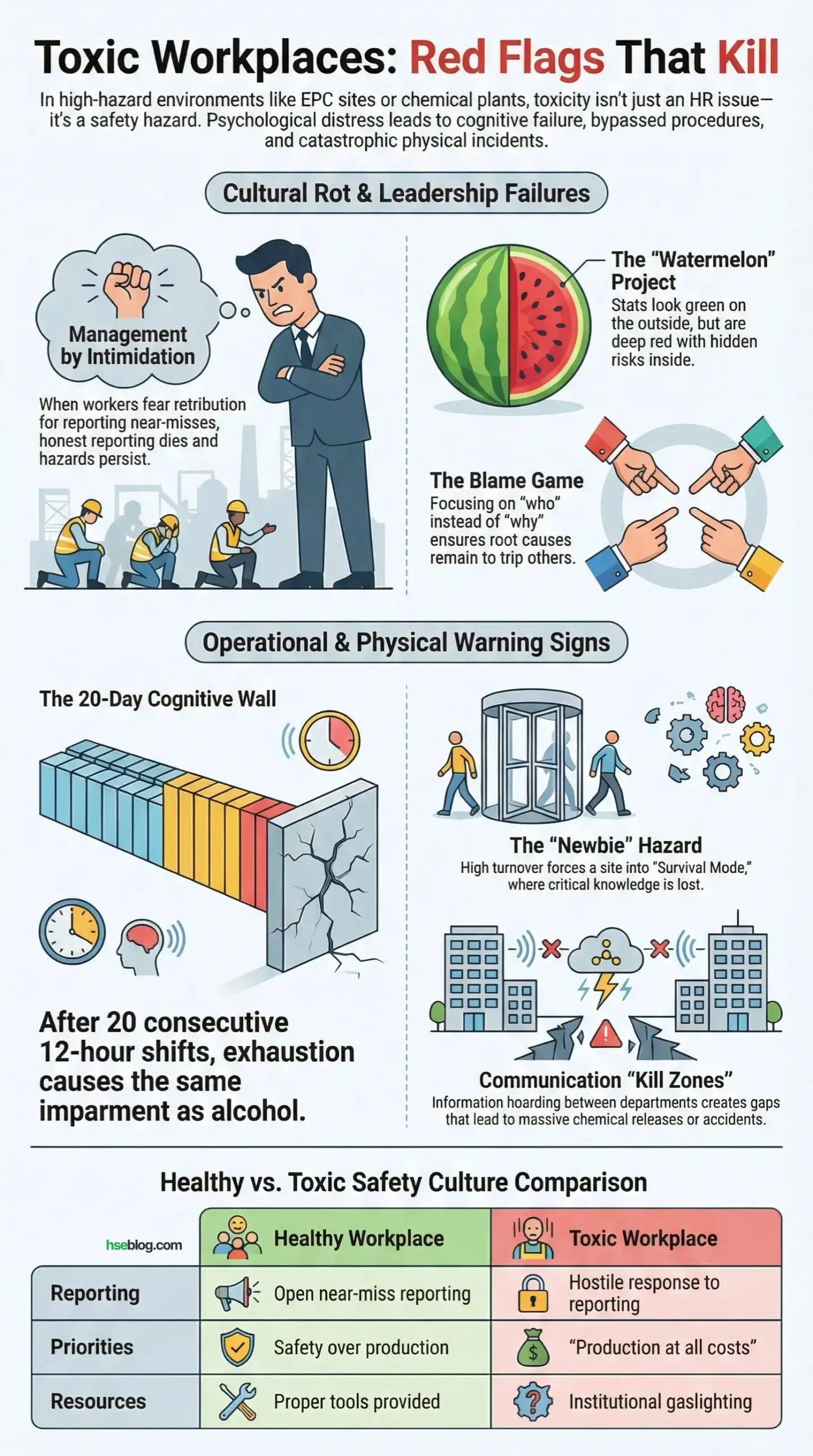

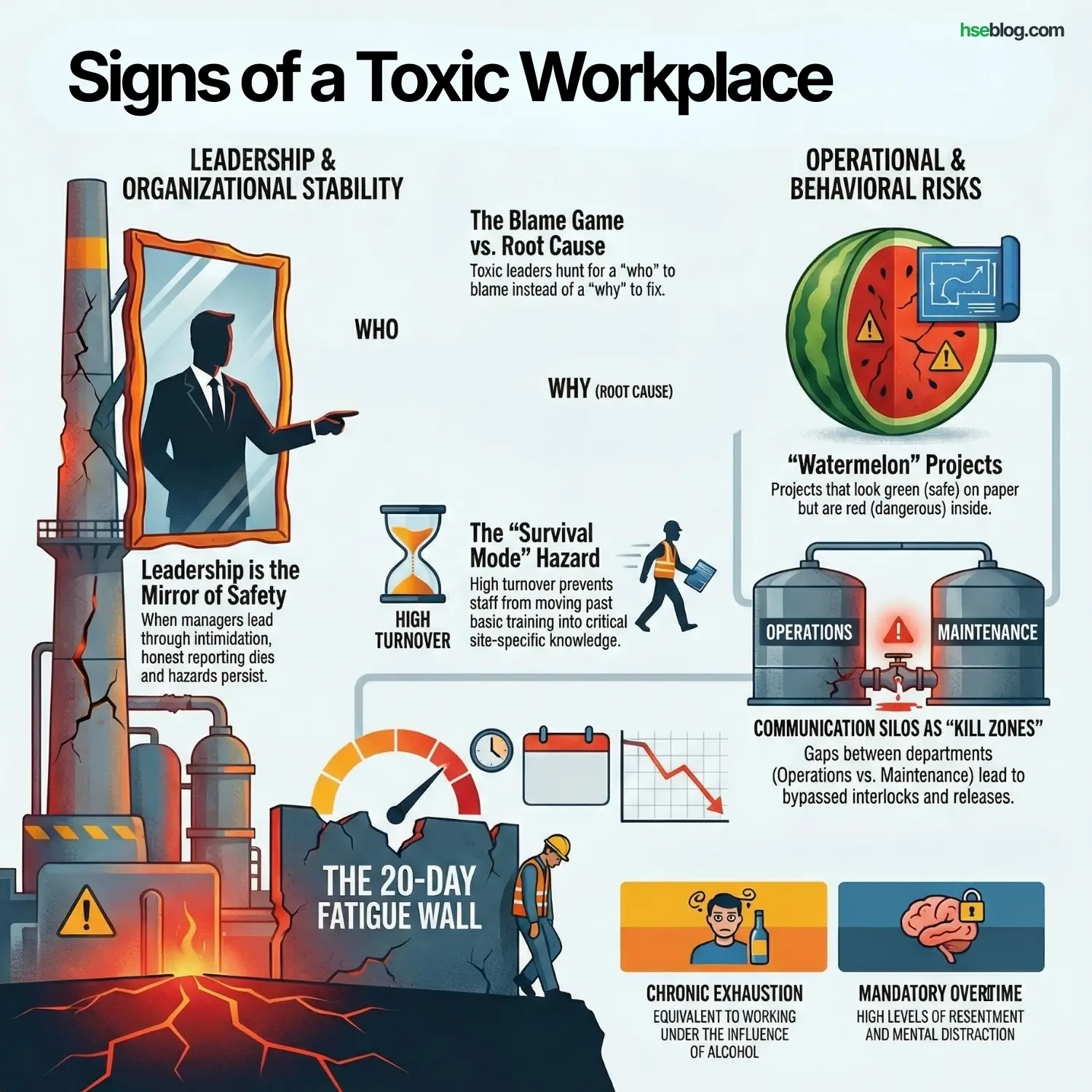

1. Poor Leadership: The Root of Cultural Rot

In my years on-site, I’ve learned that a site’s safety record is a mirror of its leadership’s character. When a manager leads through intimidation, the first thing that dies is honest reporting. If a worker knows they’ll be screamed at for stopping a job to address a hazard, they will simply keep their head down and let the hazard persist.

- The Favoritism Trap: Inconsistency is a poison. When the “star” welder is allowed to work without a harness because he’s fast, but a new hire is written up for a minor PPE lapse, the safety program loses all credibility.

- The Blame Game: Toxic leaders look for a “who” rather than a “why.” By blaming an individual for a slip or trip instead of investigating the poor lighting or leaking valve, they ensure the root cause remains to trip the next person.

2. High Turnover Rate: The Loss of Critical Knowledge

I once audited a chemical plant where the turnover for Permit-to-Work (PTW) Coordinators was less than six months. This is a massive red flag because these roles require deep, site-specific knowledge of piping and instrumentation.

- The “Newbie” Hazard: When you are constantly training new staff, you never move past “Survival Mode.” There is no continuity, and critical safety shortcuts begin to be treated as “standard practice” by people who don’t know better.

- Exit Interview Reality: If people are leaving high-paying roles in droves, they aren’t chasing more money—they are fleeing a fire. In heavy industry, high turnover usually means the workforce has lost faith in management’s ability to keep them safe.

3. Unhealthy Competition: Sabotaging Collective Safety

Competition can be healthy, but in a toxic workplace, it becomes a zero-sum game. I’ve seen civil crews hide specialized rigging equipment from the mechanical team just to ensure their own KPIs looked better at the end of the shift.

- KPI Manipulation: When bonuses are tied strictly to “zero reported incidents,” teams will actively pressure injured coworkers not to report a cut or a strain. This creates a “watermelon” project: green on the outside (the stats look great), but deep red on the inside (full of hidden risks).

- Fragmentation: Safety is a team sport. When teams view each other as rivals, they stop performing the “brother’s keeper” checks that prevent fatalities in high-risk zones.

4. Lack of Work-Life Balance: The Fatigue Factor

We talk about “Safety Culture,” but we rarely talk about “Sleep Culture.” In my investigations, I’ve found that chronic overwork is as dangerous as working under the influence of alcohol. A toxic workplace views “exhaustion” as a badge of honor rather than a biological hazard.

- The 20-Day Wall: After 14 to 20 consecutive days of 12-hour shifts, cognitive function drops significantly. Reaction times slow, and “micro-sleeps” occur behind the wheels of heavy machinery.

- Resentment & Distraction: Workers who never see their families because of mandatory “voluntary” overtime are mentally checked out. A distracted mind on a scaffolding rig is a recipe for a fall.

5. Poor Communication: Information as a Weapon

In a healthy site, communication flows like water—everywhere. In a toxic one, it’s a “need to know” basis. I have seen incidents where a night shift team bypassed a safety interlock but failed to tell the day shift, leading to a massive chemical release during startup.

- The Silo Effect: When departments (Operations vs. Maintenance vs. HSE) don’t talk, the gaps between them become “kill zones.”

- Management Secrecy: If workers are kept in the dark about upcoming layoffs or project changes, the rumor mill takes over, and focus on the task at hand evaporates.

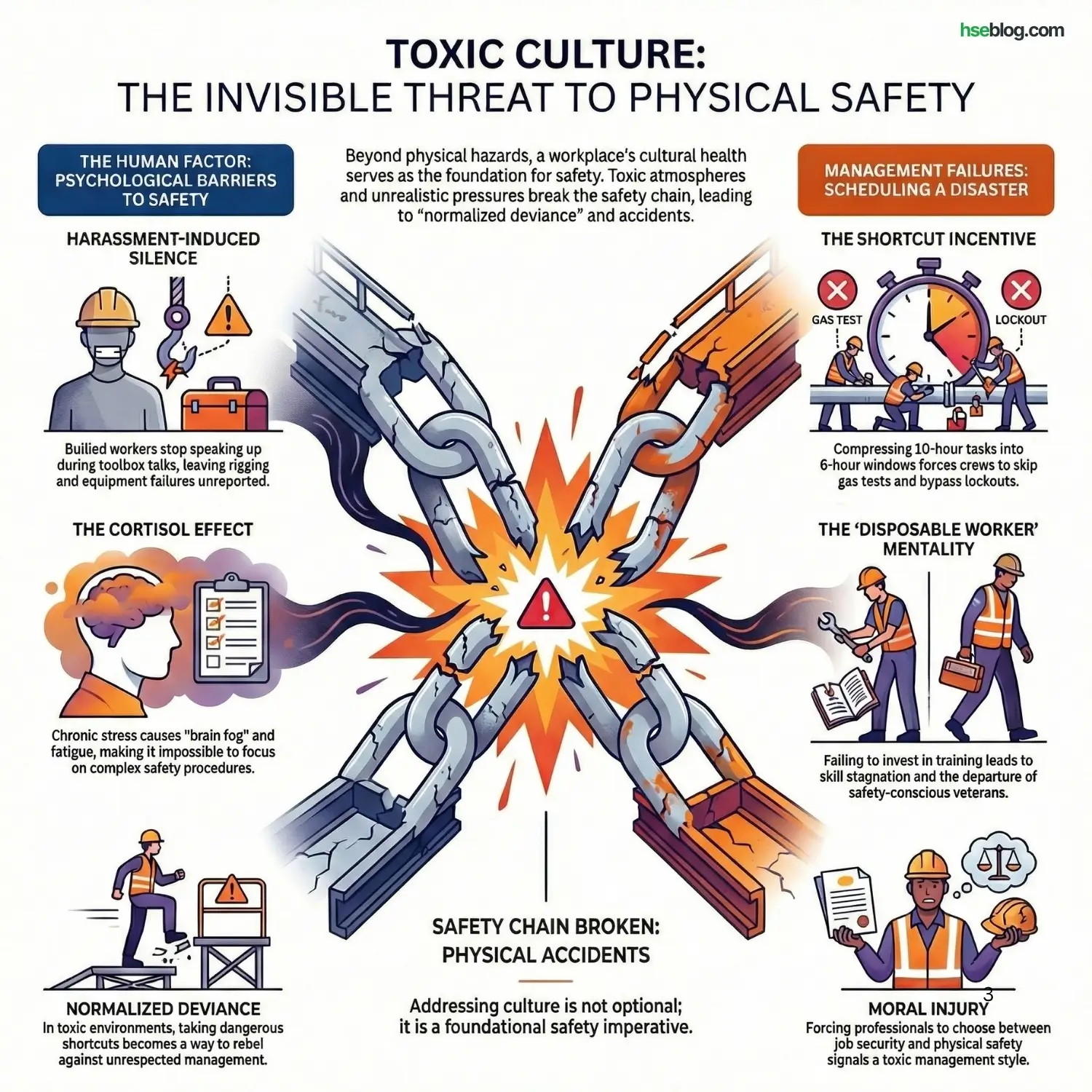

6. Discrimination and Harassment: Breaking the Safety Chain

I have intervened in situations where “old school” crews bullied younger workers or those from different backgrounds. This isn’t just about “feelings”—it’s about the fact that a bullied worker will not speak up during a tool-box talk if they see a rigging failure.

- Targeted Distraction: Harassment creates intense psychological stress. A worker who is busy looking over their shoulder for a bully isn’t looking at the forklift approaching them.

- Erosion of Trust: Safety relies on the “Stop Work Authority.” If a worker feels marginalized, they won’t feel empowered to use that authority, even when they see a life-threatening error.

7. Negative Atmosphere: The Precursor to Negligence

A toxic atmosphere is a “vibe” backed by data. When you walk into a mess hall and the only talk is about how “management doesn’t care” or “safety is just a joke,” you are looking at a site that has given up.

- The Sarcasm Shield: When safety protocols are met with eye-rolls and sarcasm, it means the workforce has seen too many “safety slogans” and not enough “safety actions.”

- Normalized Deviance: In a negative atmosphere, taking shortcuts becomes a way to “rebel” against a management that isn’t respected. This normalization of deviance is how major disasters like Deepwater Horizon begin.

8. Unrealistic Expectations: The Production vs. Safety War

In the field, we call this “scheduling a disaster.” When a Project Manager sets a timeline that ignores cure times, weather delays, or mandatory rest periods, they aren’t being “ambitious”—they are being reckless.

- The Shortcut Incentive: If a crew is told they must finish a 10-hour task in 6 hours, the first thing they drop isn’t the work; it’s the safety check. They’ll skip the gas test, ignore the lanyards, and bypass the lockout.

- Moral Injury: Forcing a professional to choose between their job security and their physical safety is the ultimate sign of a toxic management style.

9. Lack of Professional Development: The “Disposable Worker” Mentality

I’ve walked onto sites where the “refresher training” was just a sign-in sheet passed around during lunch. When a company stops investing in your skills, they’ve decided you are a depreciating asset.

- Skill Stagnation: In high-risk industries like Oil & Gas or Renewables, technology and standards change. Without ongoing training, your team is operating on obsolete safety knowledge.

- Devaluation: A lack of development tells the worker, “We don’t see a future for you here.” This leads to a total lack of loyalty, which is when the high-quality, safety-conscious veterans start looking for the exit.

10. Employee Health Issues: The Invisible Hazard

As an HSE practitioner, I look at the sick bay logs as closely as the incident logs. If there’s a spike in gastric issues, migraines, or “mental health days,” the workplace is toxic.

- The Cortisol Effect: Constant stress from a “bully boss” keeps the body in a state of high alert. This causes physical fatigue and “brain fog,” making it nearly impossible for a worker to focus on complex safety procedures.

- Psychosomatic Warning: When workers start feeling sick before they even arrive at the gate, the environment has become bio-hazardous to their mental well-being.

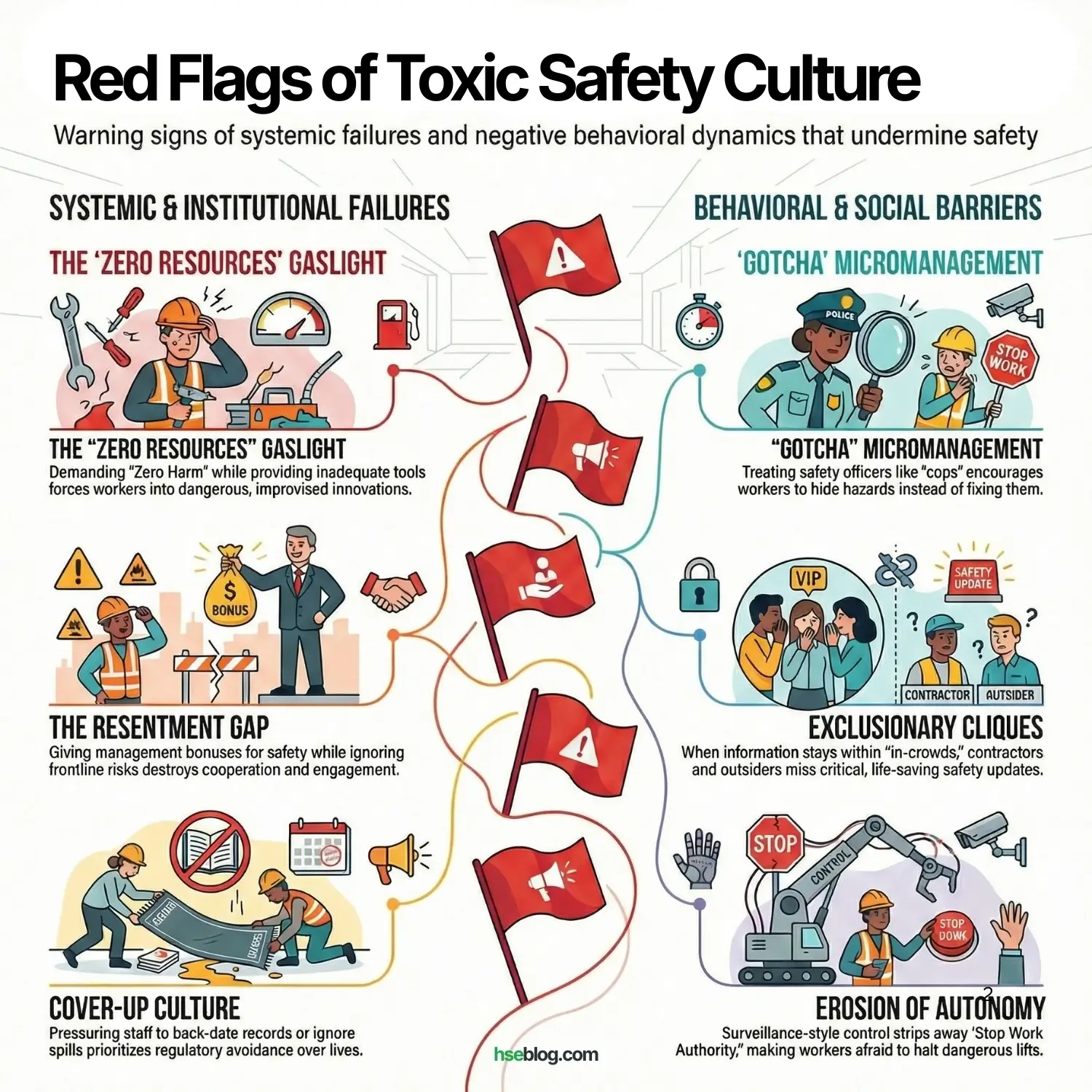

11. Lack of Recognition or Compensation: The Resentment Gap

Safety is a thankless job—until something goes wrong. If a crew works a month of nights in the rain to hit a milestone safely, and the only “reward” they get is a more aggressive schedule for next month, they will burn out.

- The “Safety Bonus” Irony: I’ve seen companies give massive bonuses to managers for “Low TRIR” while the workers who actually took the risks get nothing. This creates a “them vs. us” divide that kills cooperation.

- Disengagement: A worker who feels unappreciated will stop going the extra mile. They won’t tighten that loose bolt they see; they’ll leave it for “the next guy.”

12. Micromanagement: Surveillance vs. Safety

There is a massive difference between “High Oversight” and “Micromanagement.” A micromanager doesn’t want you to be safe; they want you to be compliant and controlled.

- The “Gotcha” Culture: When HSE officers act like “Safety Cops” looking for a reason to write a ticket, workers become experts at hiding hazards. They’ll hide the frayed sling the moment they see the white truck coming.

- Loss of Autonomy: Micromanagement strips away a worker’s “Stop Work Authority.” If they can’t even choose their own tool without being questioned, they won’t feel empowered to stop a multi-million dollar lift when something feels “off.”

13. Ethical and Legal Violations: The Point of No Return

This is where I tell my juniors to pack their bags. If you are asked to back-date a training record or ignore a spill to avoid a regulatory fine, the company has no “Safety Culture”—it has a “Cover-Up Culture.”

- The Scapegoat Strategy: Toxic firms love to have an HSE Manager sign off on bad paperwork so that when the incident happens, they can blame the “failed oversight” of the individual rather than the systemic pressure.

- The Integrity Test: Once you compromise your ethics once, management knows they “own” you. The pressure to lie only gets stronger.

14. Inadequate Resources: Institutional Gaslighting

I once inspected a site where workers were using duct tape to “repair” fall-protection harnesses because the warehouse was out of stock. Demanding “Zero Harm” while providing “Zero Resources” is an insult to the profession.

- Dangerous Innovation: When the right tool isn’t available, workers use the wrong tool. They’ll use a screwdriver as a chisel or a forklift as a man-lift.

- Resource Hoarding: In toxic sites, the “Inner Circle” gets the new PPE and the working trucks, while the contractors get the scrap.

15. Exclusion and Cliques: The Breakdown of the PTW

Safety relies on the “Permit-to-Work” (PTW) being a collaborative process. When “cliques” form—usually based on tenure, nationality, or department—information stops flowing to those who need it most.

- The “In-Crowd” Blindness: If the supervisors only talk to their “friends” in the morning meeting, the sub-contractors or the “outsiders” miss critical safety updates.

- Isolation Risks: In an emergency, cliques fall apart. If you haven’t built a team that trusts each other across the board, you won’t have a team that saves each other when the alarm sounds.

Conclusion

A toxic workplace is more than just a “bad job”—it is a high-risk environment that threatens your mental health and physical safety. As an HSE professional, my duty has always been to protect life, and that includes protecting workers from the slow-motion disaster of a poisonous culture. If you recognize these red flags, do not ignore them. Document the issues, use the official reporting channels, and if the toxicity is systemic and unchangeable, recognize that no paycheck is worth a permanent injury or the loss of your professional integrity.

Safety is not just about hard hats and harnesses; it is about a culture of respect, transparency, and the courage to do what is right even when the pressure is on.